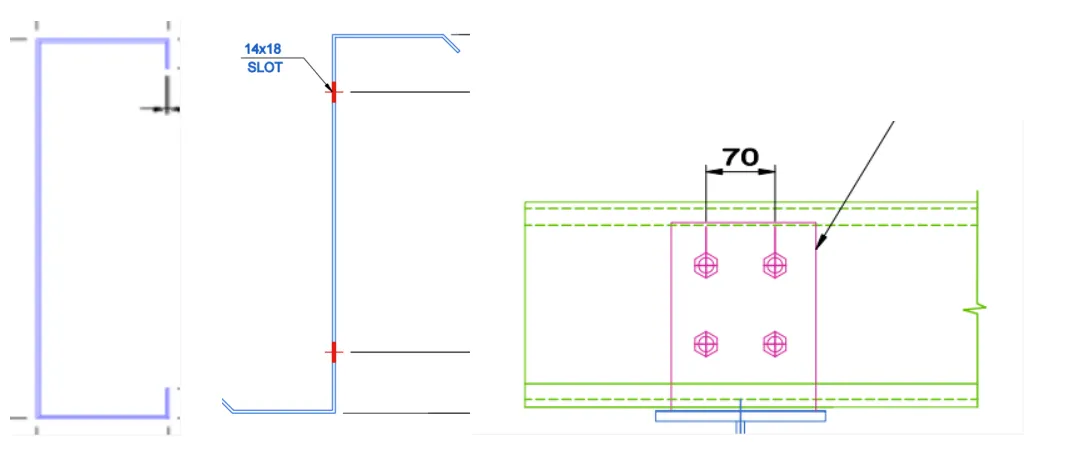

Drawings

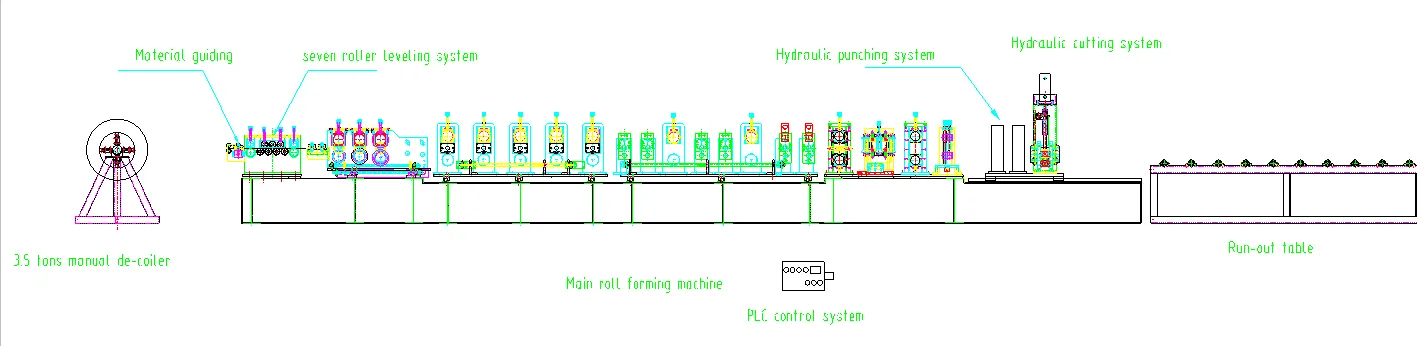

Flow chat

Component

|

Hydraulic decoiler |

1 set |

|

Feed guide |

1 set |

|

Leveling device |

1 set |

|

Main forming machine |

1 set |

|

Hydraulic punching |

1 set |

|

Hydraulic cutting system |

1 set |

|

Hydraulic station |

1 set |

|

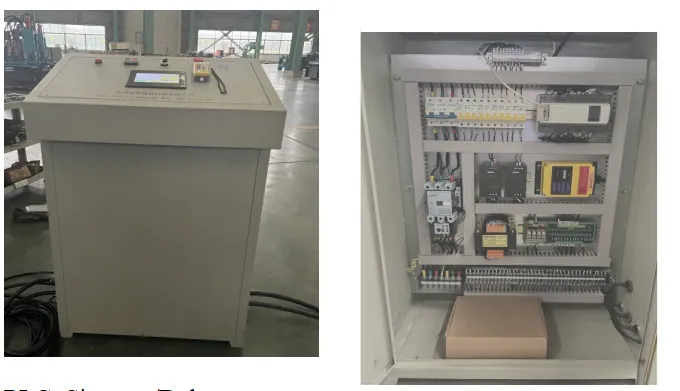

PLC control system |

1 set |

|

Receiving table (3M * 2) |

1 set |

Parameters And Specification

|

|

|

|

|

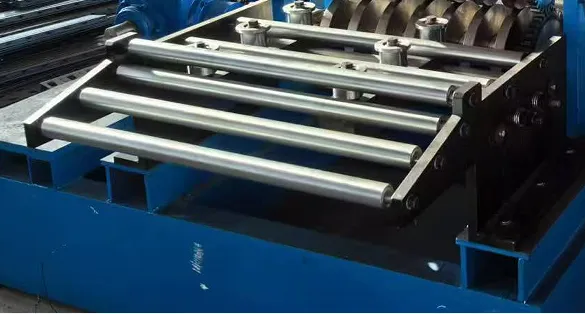

Leveling device

|

|

|

Main Forming machine 1> ① The width of C (122-342mm) and Z (122-342mm) can be changed during that; ② The waist height (53-99mm) can be changed freely; ③ Small edge (15-25mm); ④ Plate thickness t (1.5-3.0mm) adjustable 2> Material application: Q195, Q235 hot-rolled strip steel or hot-rolled galvanized strip steel (1.5-3.0mm) 3> Main forming: 16 stand 4>.Roller material: GCr15, process: heat treatment after CNC processing to HRC58-60, finish turning, polishing and electroplating 5>.shafts material:40Cr Processing technology: after numerical control processing, HRC28-32 is modulated, and then finish turning, polishing and electroplating 6>.Forming speed:0-15m/min 7>.Molding machine type: memorial archway chain drive 8>.Roller form: Adopting a split type roller conveyor on both sides, with a spindle insertion type transmission 9>.Main shaft diameter: Φ 85mm (insert part shaft diameter 65mm) 10>Main power:18.5kw 11> Type change mode: Automatic change size, (three type change motors: 0.75 * 2+1.5kw*1) |

|

Hydraulic punching 1>Adjustment range: 45~300mm 2>Structural form: One set of punching machine power source is the downward pressure of the oil cylinder 3>Punching plate thickness: ≤ 3.0mm 4>Horizontal adjustment method for punching hole distance: manual 5>Number of punching molds: 1 set |

|

|

|

|

|

|

Hydraulic station 1> Hydraulic station: hydraulic station power 11KW 2> Fuel tank capacity 350L

|

|

Receiving table 1> Supporting material length: 2m* 2 pieces

2>Material supporting method: the frame is welded with channel steel and angle steel, and the galvanized passive roller installed on the surface will not damage the galvanized layer of profile steel |

|

|

Products |

|