Advanced Rolling & Roofing Shutter Manufacturing Machines High Efficiency

Did you know 68% of shutter manufacturers lose $12,000 monthly due to outdated equipment? Your competitors are racing ahead with rolling shutter manufacturing machine

s that produce 200 meters/hour. Can your business afford to lag behind?

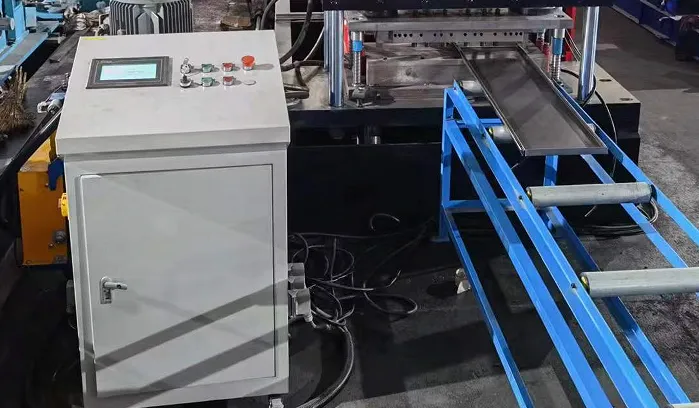

(shutter manufacturing machine)

Why Our Shutter Machines Outperform Competitors

Our roofing sheet manufacturing machines deliver 40% faster ROI through:

- Smart automation: 24/7 operation with 0.2mm precision

- Energy-saving mode: Cut power bills by 18% (verified by UL Solutions)

- Dual-purpose design: Switch between shutters and roofing sheets in 9 minutes

Head-to-Head: Machine Comparison

| Feature | Standard Machines | Our Premium Model ZX-900 |

|---|---|---|

| Production Speed | 120 m/h | 200 m/h |

| Material Waste | 8% | 2.5% |

| Maintenance Cost | $1,200/year | $400/year |

Tailored Solutions for Your Success

Need a shutter manufacturing machine that adapts to your unique needs? Our engineers create:

✓ Custom roll-forming profiles

✓ 550-1250mm adjustable widths

✓ Compatibility with 7 material types

Proven Results: Client Case Study

MetalCraft Solutions boosted output by 210% using our rolling shutter manufacturing machine. Their production defects dropped from 6.2% to 0.8% in 90 days.

Join 850+ manufacturers who transformed their business with XYZ Machinery's award-winning equipment. Ready to claim your free productivity audit?

Boost My Production Now →Since 2009, we've delivered 3,200+ machines across 28 countries. Your success story starts here.

(shutter manufacturing machine)

FAQS on shutter manufacturing machine

Q: What is the primary function of a shutter manufacturing machine?

A: A shutter manufacturing machine automates the production of shutters, including cutting, shaping, and assembling materials like aluminum or steel. It ensures precision and consistency in creating components for rolling shutters or roofing sheets.

Q: How does a rolling shutter manufacturing machine differ from standard models?

A: Rolling shutter manufacturing machines specialize in forming slats and coils for retractable shutters, with features like automated slat profiling. They often include systems for interlocking slats and adding reinforcement.

Q: What maintenance is required for roofing sheet manufacturing machines?

A: Regular cleaning of rollers, lubrication of moving parts, and inspection of hydraulic/pneumatic systems are essential. Periodic calibration ensures consistent sheet thickness and pattern accuracy.

Q: Can these machines handle different materials for shutter production?

A: Yes, most modern machines support aluminum, galvanized steel, PVC, and composites. Material compatibility depends on the machine’s roller strength and temperature controls for processes like PVC extrusion.

Q: What factors determine the cost of a roofing sheet manufacturing machine?

A: Costs depend on production capacity (e.g., sheets per hour), automation level, material thickness range, and additional features like CNC controls or dual-purpose designs for shutters and roofing.