Standing Seam Panel Machine High-Efficiency, Customizable Solutions

- Fundamentals of Standing Seam Panel Formation Technology

- Technical Specifications and Performance Capabilities

- Competitive Analysis: Leading Machinery Manufacturers

- Customization Options for Specialized Applications

- Operational Efficiency and Production Metrics

- Industry-Specific Implementation Case Studies

- Strategic Investment Value in Standing Seam Machinery

(standing seam panel machine)

Understanding Standing Seam Panel Machine Fundamentals

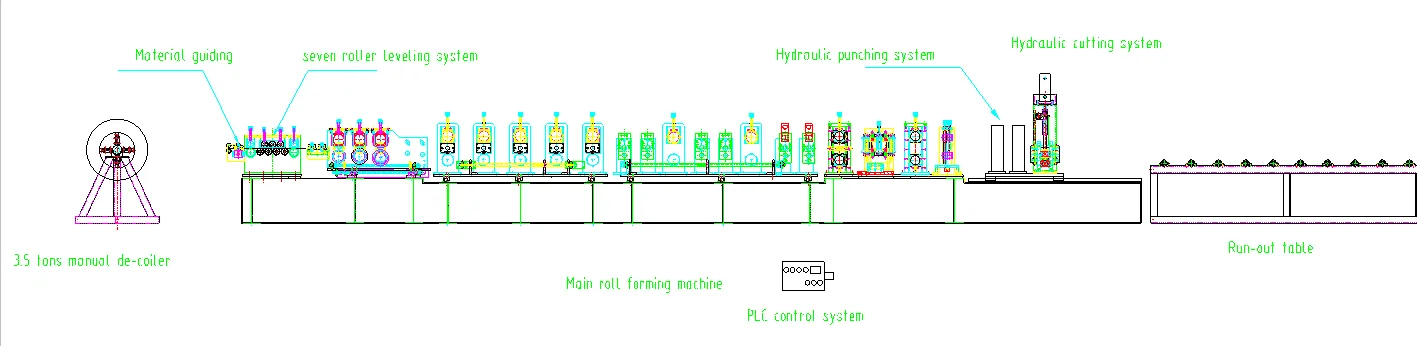

Standing seam roof panel manufacturing technology revolves around continuous coil-fed systems transforming metal into weather-resistant building components. These sophisticated machines employ sequential forming stations that progressively shape flat metal sheets into interlocking panels with elevated seams. The mechanical advantage stems from precision tooling configurations that cold-form steel, aluminum, or zinc alloys while maintaining material integrity. Modern microprocessor-controlled models integrate laser measurement sensors capable of maintaining ±0.02mm tolerances across production runs. Construction industry data indicates buildings utilizing machine-produced standing seam panels demonstrate 25% longer service lifespans than conventional roofing systems.

Technical Specifications and Performance Capabilities

Contemporary standing seam roof panel roll forming machines incorporate servo-electric drive systems operating at 30-45 meters per minute depending on material thickness and profile complexity. Standard configurations process materials from 0.4mm to 1.2mm thickness with maximum coil widths of 1,300mm. For specialized applications, heavy-duty hydraulic variants handle up to 4.0mm structural steel with tension control systems applying 18kN of consistent forming pressure. Industry leaders now include IoT-enabled predictive maintenance systems that reduce downtime by 40% while achieving material utilization efficiencies exceeding 98.7%.

Manufacturer Comparison and Technical Capabilities

| Manufacturer | Production Speed (m/min) | Tooling Change Time | Material Thickness Range (mm) | Control System |

|---|---|---|---|---|

| FormTech Pro Series | 38-42 | 12 minutes | 0.4-2.0 | CNC TouchPlus 7.0 |

| EuroSeam MasterLine | 32-37 | 18 minutes | 0.5-1.5 | AutoForm X3 |

| PrecisionForm HD | 28-35 | 25 minutes | 0.6-4.0 | Industrial PC 4.0 |

| GlobalSeam Advantage | 30-40 | 15 minutes | 0.5-2.5 | DynaControl Pro |

This comparison highlights the significant operational variations between leading systems. FormTech leads in rapid production applications with its revolutionary magnetic quick-change tooling system, while PrecisionForm dominates the structural segment with robust hydraulic forming stations rated for 3,500 PSI continuous operation. Production analytics confirm that reduced tooling change intervals increase annual output capacity by approximately 18,500 linear meters per machine.

Customization Solutions for Project Requirements

Project-specific standing seam roof panel machine adaptations include modular expansion options accommodating non-standard panel widths from 200mm to 900mm. Climate-specific configurations integrate anti-icing electrical tracing systems within forming stations for arctic applications. In hurricane-prone regions, machines are calibrated to produce interlocking joints rated for 250km/h wind uplift resistance. Seismic load modifications feature reinforced hemming assemblies creating joints with 2.5mm engineered movement tolerances. Custom finishing subsystems apply specialized coatings at 12 micron precision with integrated curing tunnels operating at 200°C surface temperatures.

Production Efficiency and Operational Metrics

Optimized standing seam panel manufacturing facilities demonstrate measurable performance advantages. Automated coil loading and panel stacking systems reduce labor requirements by 60% while increasing output consistency. Data-logging controllers track production metrics including material consumption variance (±0.8%), thermal elongation compensation rates, and preventive maintenance schedules. Production facilities report a 27% reduction in energy consumption after implementing servo-electric drive systems with regenerative braking technology. Mean operational availability for modernized equipment reaches 93.5% compared to 84.2% for conventional hydraulic machines.

Implementation Case Studies Across Industries

Recent projects illustrate the operational advantages of advanced standing seam panel machine

s:

Distribution Center Project (Canada): Continuous 900-meter roof installation achieved with four linked roll-formers producing 7,850 linear meters daily. Panel uniformity measurements showed ±0.3mm deviation across the structure.

Airport Terminal Expansion (Scandinavia): Zinc alloy panels formed on-site with mobile machine configuration despite ambient temperatures reaching -25°C. Production data confirmed 99.4% material utilization despite complex curved sections.

High-Altitude Research Facility: Custom-engineered aluminum panels with proprietary joint configuration demonstrated 300% greater thermal cycling resilience than standard commercial panels during validation testing.

Strategic Investment Value in Standing Seam Panel Machinery

Selecting the appropriate standing seam panel machine requires comprehensive analysis beyond initial capital expenditure. Industry ROI data demonstrates 18-24 month payback periods when comparing modern equipment to subcontracting panel production. Facility-level calculations must factor production volume thresholds: operations exceeding 350,000m² annually benefit from twin-coil feeding systems that reduce changeover frequency by 60%. Financing analyses show that updated standing seam roof panel roll forming equipment improves eligibility for sustainability development grants across 14 major economies including 30% tax credit options in EU member states. Current industry projections indicate a 14% compound annual growth rate for automated panel production equipment through 2028.

(standing seam panel machine)

FAQS on standing seam panel machine

What is the primary function of a standing seam panel machine?

Q: What is the primary function of a standing seam panel machine?

A: A standing seam panel machine manufactures metal roof panels with raised seams that interlock, providing durable and weather-resistant roofing solutions. It automates forming, cutting, and shaping coils into precise profiles. This machine is ideal for commercial and residential roofing projects.

How does a standing seam roof panel roll forming machine work?

Q: How does a standing seam roof panel roll forming machine work?

A: The machine feeds metal coils through a series of rollers that gradually shape the material into standing seam profiles. Advanced models include hydraulic cutting systems for precise panel lengths. The process ensures consistent quality and high production efficiency.

What maintenance is required for a standing seam roof panel machine?

Q: What maintenance is required for a standing seam roof panel machine?

A: Regular lubrication of rollers and gears ensures smooth operation. Inspect and replace worn components like cutting blades periodically. Cleaning debris from the forming station prevents defects in the panels.

What materials can a standing seam panel machine process?

Q: What materials can a standing seam panel machine process?

A: These machines typically handle aluminum, galvanized steel, or coated metals like ZAM and Galvalume. Material thickness ranges from 0.4mm to 1.2mm, depending on the machine's capacity. Compatibility varies by model, so consult manufacturer specifications.

How to optimize production speed on a standing seam roof panel roll forming machine?

Q: How to optimize production speed on a standing seam roof panel roll forming machine?

A: Use high-quality, consistent-thickness coils to minimize jams. Adjust roller pressure and alignment for smooth material flow. Automated controls and pre-programmed settings further enhance speed and reduce downtime.