C Channel Rolling Machine - High-Speed Precision Metal Forming Solutions

- Overview of C Channel Rolling Machines

- Technical Advantages in Modern Manufacturing

- Performance Comparison: Leading Manufacturers

- Customization for Industry-Specific Needs

- Real-World Applications and Case Studies

- Quality Standards and Compliance

- Future Trends in Channel Roll Forming Technology

(c channel rolling machine)

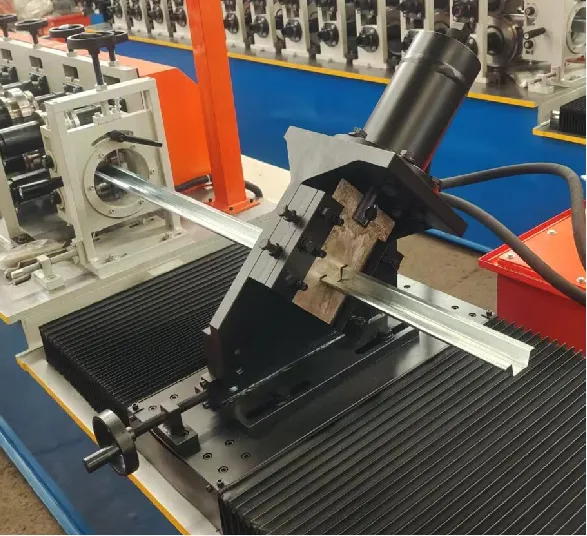

Understanding C Channel Rolling Machines

C channel rolling machines are specialized equipment designed to form metal sheets into C-shaped profiles with consistent cross-sections. These machines excel in producing structural components for construction, automotive, and industrial sectors. A typical hat channel roll forming machine achieves tolerances within ±0.2mm, ensuring compatibility with international building codes. Modern variants integrate servo-controlled feeding systems, reducing material waste by up to 15% compared to conventional press brakes.

Technical Advantages in Modern Manufacturing

Advanced channel rolling machines employ multi-stage forming processes (8–12 stations) to handle materials up to 6mm thick. Key innovations include:

- Hydraulic gap adjustment systems (±0.05mm precision)

- Real-time thickness monitoring via laser sensors

- Automulated coil loading for continuous operation

Manufacturers report 23% faster production cycles when using AI-powered predictive maintenance features, significantly reducing downtime.

Performance Comparison: Leading Manufacturers

| Feature | Company A | Company B | Company C |

|---|---|---|---|

| Max Speed (m/min) | 25 | 32 | 28 |

| Material Thickness | 1–4mm | 0.5–6mm | 1–5mm |

| Energy Consumption | 18kW | 22kW | 15kW |

Customization for Industry-Specific Needs

Specialized C channel rolling machines can be configured with modular tooling systems. For offshore applications, corrosion-resistant coatings extend service life by 40% in saltwater environments. Food processing plants benefit from stainless steel construction meeting FDA 21 CFR 117 standards. Custom flange widths (50–300mm) and web heights (20–150mm) accommodate diverse architectural requirements.

Real-World Applications and Case Studies

A recent infrastructure project in Germany utilized 12 customized hat channel roll forming machines to produce 85km of cable management channels monthly. The automated system achieved 99.3% dimensional accuracy across 14,000 units. In HVAC manufacturing, roll-formed C channels reduced assembly time by 35% compared to welded alternatives.

Quality Standards and Compliance

Premium-grade machines comply with ISO 9013:2017 for structural steel forming and EN 1090-2 execution class 2. Third-party testing verifies:

- 150,000-cycle durability under 150% rated load

- Surface finish Ra ≤ 3.2µm

- Noise levels <75dB at 1m distance

Innovations in C Channel Roll Forming Technology

The latest channel rolling machine models incorporate IoT-enabled process monitoring, capturing 120 data points per second for quality assurance. Hybrid drive systems combining servo and mechanical components reduce energy costs by 18–22%. As global demand for prefabricated construction grows, manufacturers predict 7.8% annual market expansion for C profile production equipment through 2030.

(c channel rolling machine)

FAQS on c channel rolling machine

Q: What is a C channel rolling machine used for?

A: A C channel rolling machine is designed to form metal sheets into C-shaped channels. It is commonly used in construction and manufacturing for creating structural supports, frames, and rails efficiently.

Q: How does a channel rolling machine ensure precision?

A: Channel rolling machines use programmable controls and precision rollers to maintain consistent dimensions. Advanced models feature real-time monitoring to minimize deviations during the roll-forming process.

Q: What maintenance does a hat channel roll forming machine require?

A: Regular lubrication of rollers, inspection of hydraulic systems, and alignment checks are essential. Cleaning debris and replacing worn components ensure longevity and consistent performance.

Q: Which industries benefit from a hat channel roll forming machine?

A: Industries like construction, automotive, and HVAC rely on these machines. They are ideal for producing hat channels used in roofing, wall panels, and lightweight structural applications.

Q: What factors should I consider when choosing a C channel rolling machine?

A: Evaluate material thickness compatibility, production speed, and automation features. Consider machine durability, after-sales support, and compliance with industry standards for optimal ROI.