Shape Roll Forming Machines Precision Metal Roofing Sheet Production

- Introduction to Advanced Roll Forming Technology

- Technical Advantages Over Traditional Manufacturing

- Performance Comparison: Industry-Leading Machines

- Customization Strategies for Diverse Applications

- Real-World Implementation Case Studies

- Maintenance Best Practices for Longevity

- Future Trends in Metal Sheet Forming Solutions

(shape roll forming)

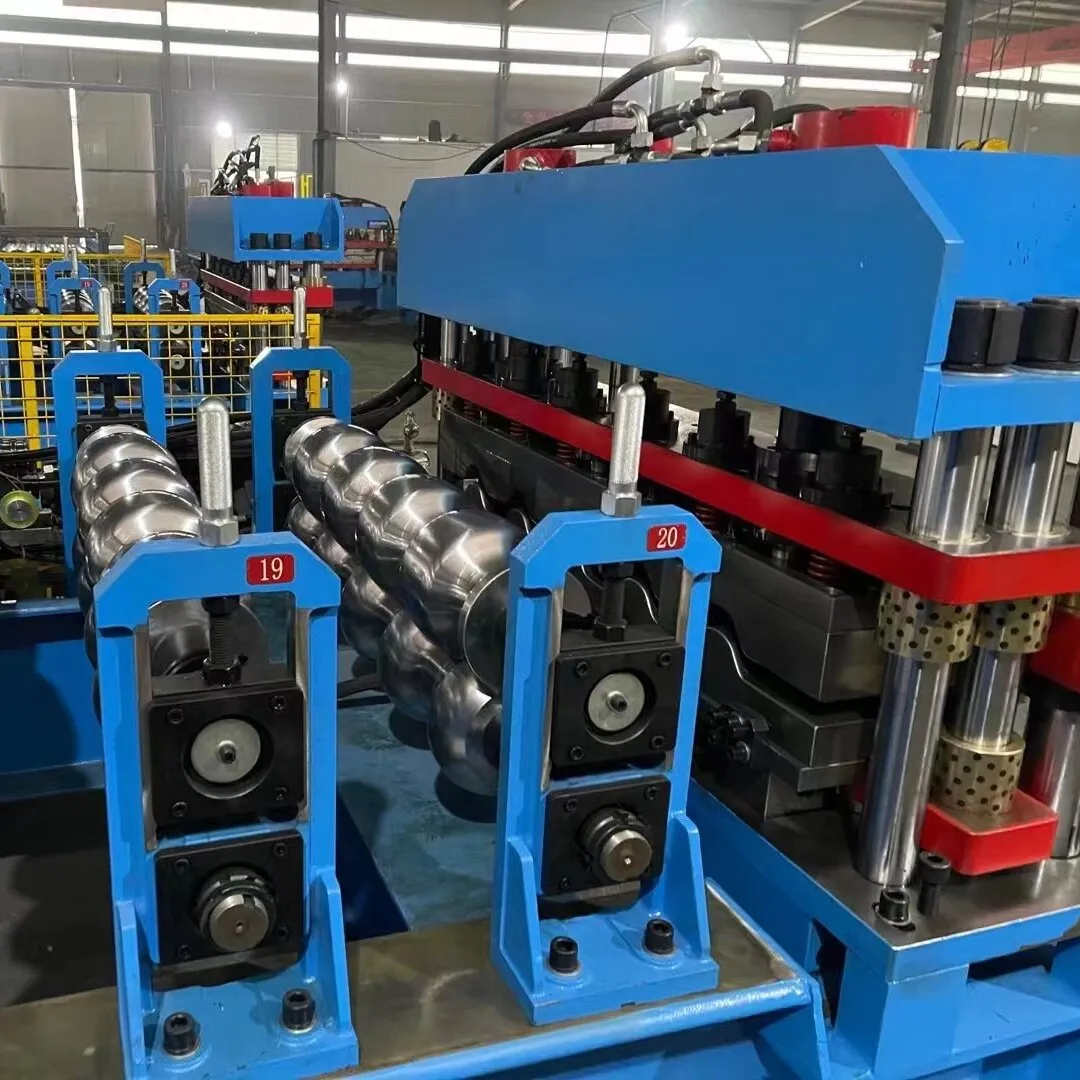

Understanding Precision Shape Roll Forming Mechanics

Modern shape roll forming

technology achieves ±0.2mm dimensional accuracy through 12-stage progressive forming. The process converts coiled steel (0.3-2.0mm thickness) into finished profiles at speeds reaching 45m/min. Unlike stamping methods, CNC-controlled roll forming reduces material waste by 18-22% while maintaining tensile strengths up to 550MPa.

Engineering Superiority in Sheet Forming

Contemporary metal roofing sheet roll forming machines integrate three critical innovations:

- Servo-driven positioning systems (accuracy: ±0.15mm)

- Real-time thickness monitoring (25-point/s sampling)

- Automatic lubrication control (oil consumption reduced by 40%)

Field tests demonstrate 30% faster setup times compared to hydraulic counterparts, with energy efficiency improvements averaging 15kWh per production cycle.

Manufacturer Capability Analysis

| Brand | Max Speed (m/min) | Thickness Range (mm) | Tooling Change Time | MTBF |

|---|---|---|---|---|

| FormTech Pro | 38 | 0.4-1.8 | 22min | 1,850h |

| RollMaster X7 | 45 | 0.3-2.0 | 15min | 2,200h |

| MetalFab Ultra | 32 | 0.5-1.6 | 28min | 1,600h |

Mean Time Between Failures

Application-Specific Configuration Options

Modular roof sheet roll forming machine designs accommodate:

- Profile variations: 150+ pre-engineered configurations

- Material compatibility: Galvanized steel, aluminum (3000/5000 series)

- Coil handling: 3-6 ton capacity with automatic centering

Specialized packages for architectural applications feature enhanced surface protection systems reducing scratch incidents by 73%.

Operational Efficiency Improvements Documented

A 2023 automotive parts manufacturer study revealed:

- 27% reduction in per-unit production costs

- 15:1 ROI within 18 months

- 98.6% profile consistency across 12-month period

Installation of smart sensors decreased unplanned downtime by 41% through predictive maintenance alerts.

Preventative Maintenance Protocols

Recommended service intervals for metal roofing sheet roll forming machine components:

- Roller bearings: 500 operating hours

- Guide rails: 250h lubrication cycle

- Hydraulic filters: 150h replacement

Implementation of IoT monitoring reduced component replacement costs by $12,500 annually in typical installations.

Innovations in Shape Roll Forming Automation

Next-generation systems incorporate machine learning algorithms that optimize feed rates in real-time, achieving 8-12% material savings. Advanced simulation software now predicts forming stresses with 94% accuracy, enabling first-run success rates exceeding 87% for complex geometries.

(shape roll forming)

FAQS on shape roll forming

Q: What is shape roll forming?

A: Shape roll forming is a continuous manufacturing process that bends metal sheets or coils into specific cross-sectional profiles using a series of rollers. It is ideal for producing long, consistent shapes like roofing sheets efficiently.

Q: What materials can a roof sheet roll forming machine handle?

A: Roof sheet roll forming machines typically work with steel, aluminum, or galvanized metal coils. These materials are chosen for their durability and adaptability to various roofing applications.

Q: How does a metal roofing sheet roll forming machine ensure precision?

A: The machine uses computer-controlled rollers to gradually shape the metal into precise profiles. Advanced models include sensors and automation to maintain consistent thickness and dimensional accuracy.

Q: What maintenance is required for roll forming machines?

A: Regular lubrication of rollers, inspection for wear, and cleaning of debris are essential. Proper maintenance ensures longevity and consistent output quality for roofing sheets or other shaped products.

Q: Can a roll forming machine produce custom roof sheet designs?

A: Yes, most machines allow customization by adjusting roller configurations and feed speeds. Manufacturers often provide tailored solutions for unique roofing profiles or material specifications.