Drywall Light Keel Roll Forming Machine – the ultimate solution for efficient and precise drywall construction. Designed for modern manufacturing needs, this state-of-the-art machine revolutionizes the way drywall keels are produced, ensuring high-quality output with minimal labor and time investment.

Nostra Drywall Light Keel Roll Formans Machina machinata est ad creandum leves carinas chalybeas quae necessariae sunt ad institutionem drywall. Cum suo provecto volumine technologiam formando, machina haec carinas varias magnitudinum et specificationum efficere potest, variis constructionis requisitis praebens. Consilium robustum firmitatem et longibilitatem efficit, eamque certam addit ad lineam productionis tuae.

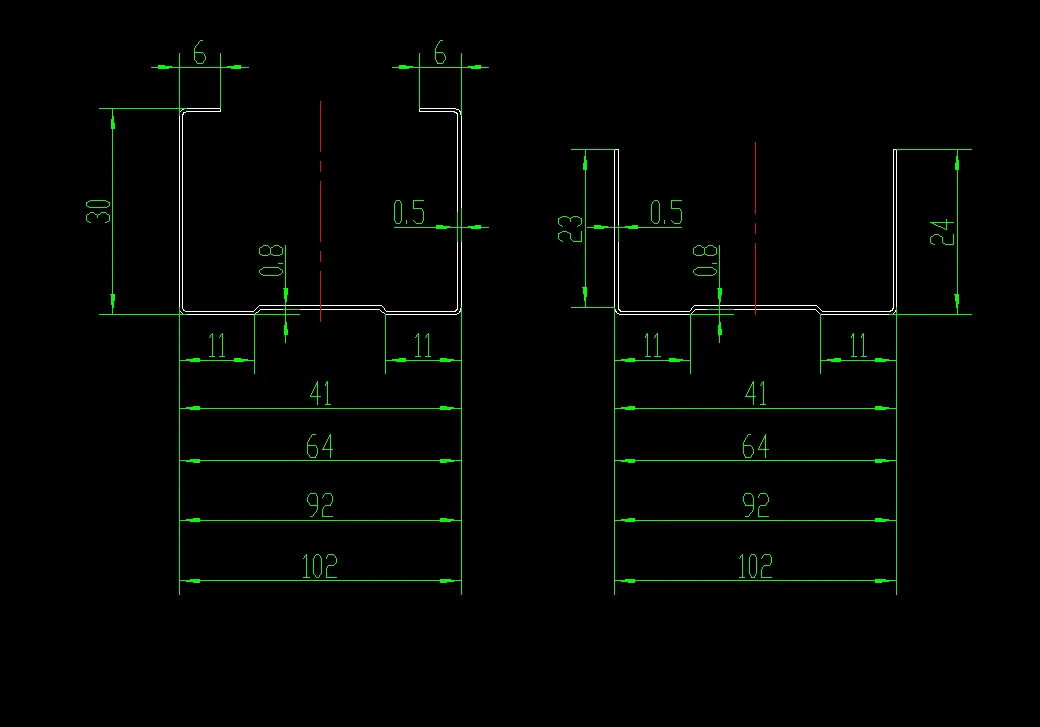

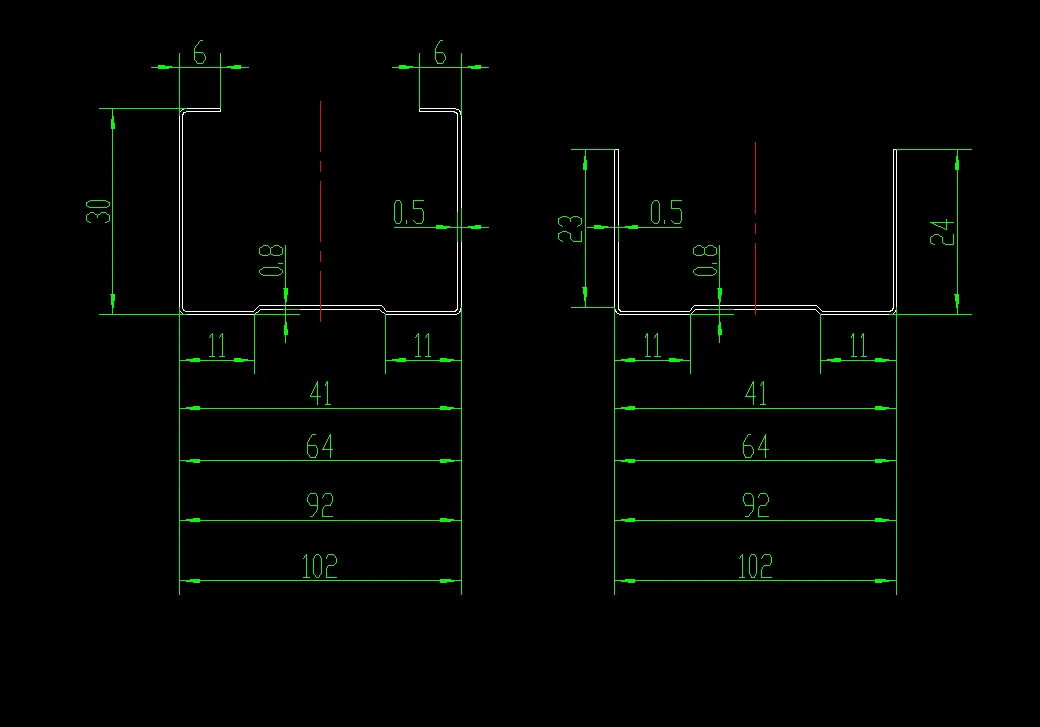

Drawings

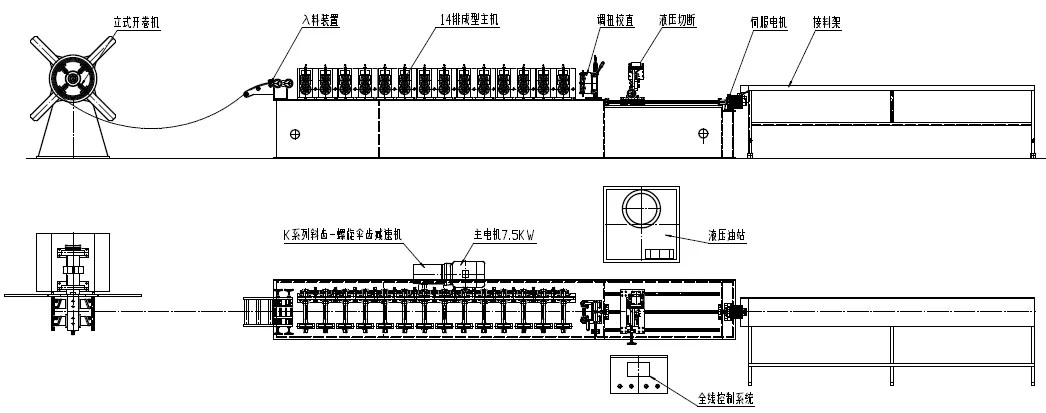

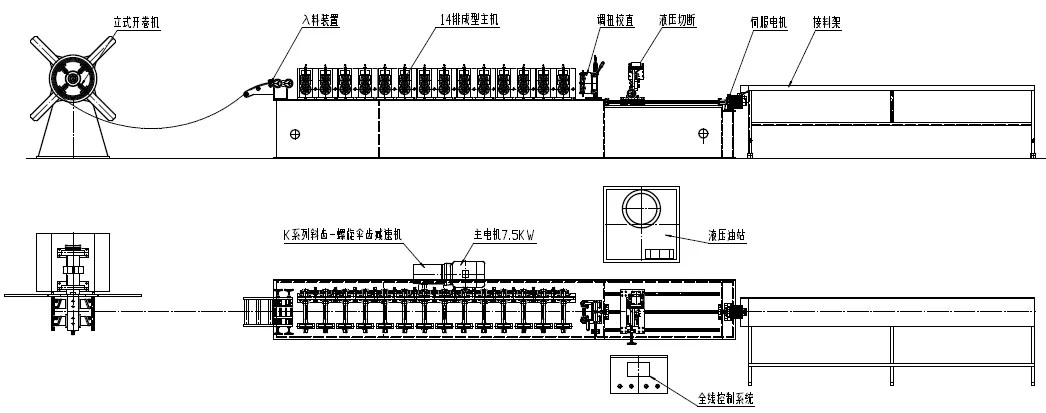

Processus et components

| Manual decoiler |

x 1 set |

| Apparatus guiding |

x 1 set |

| Pelagus volumine formatam machinam |

x 4 set |

| Servo tracking cutting system |

x 4 set |

| HYDRAULICUS station |

x 1 set |

| PLC Control system |

x 1 set |

| Currere de mensa (3M * II) |

x 1 set |

Processus working

|

Decoiler

1) Capacity: 3 tons

2). Manual decoiler

|

|

|

Materia guiding

Input width adjustable

|

|

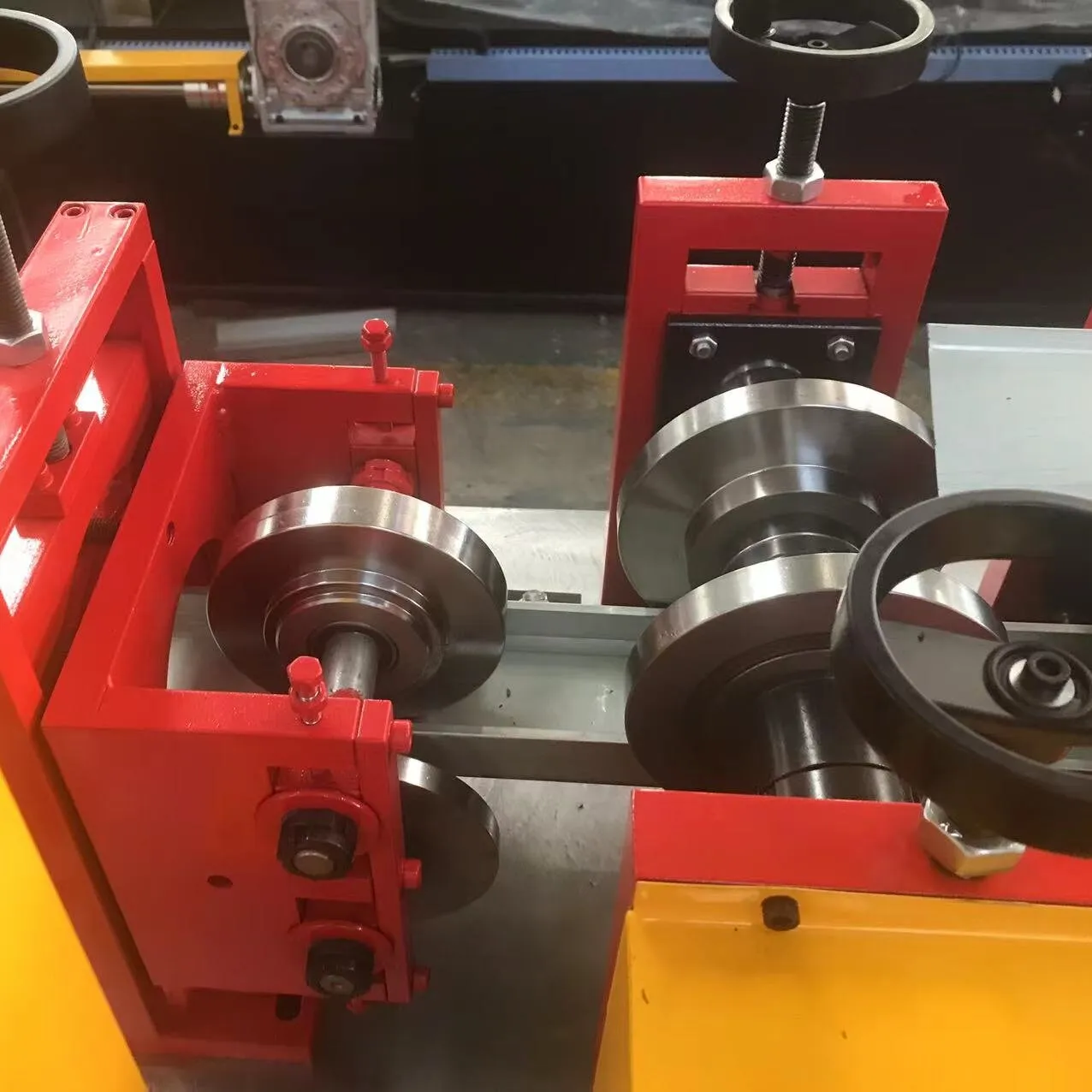

Roll machinatio

Matching material: Galvanized vel PPGI

Crassitudo materialis range: 0.3-0.9mm

Formans celeritatem: 0-40m/min

4. Praecipua potentia: 5kw,

HYDRAULICUS station: 4.0kw

5. Quantitas cylindro:10

6. Material et diametri Shaft: ¢ 50mmmaterial est 45CR

7.The via pulsis: Apparatus

8. Controlling system: PLC

9. Voltage: 380V/ 3phase/ 60 HZ

10.Material formandi scutulis: Cr12,HRC58-62

11.Material of dromonis: Cr12 ferrum fingunt cum restincto treatment,HRC 58-62℃

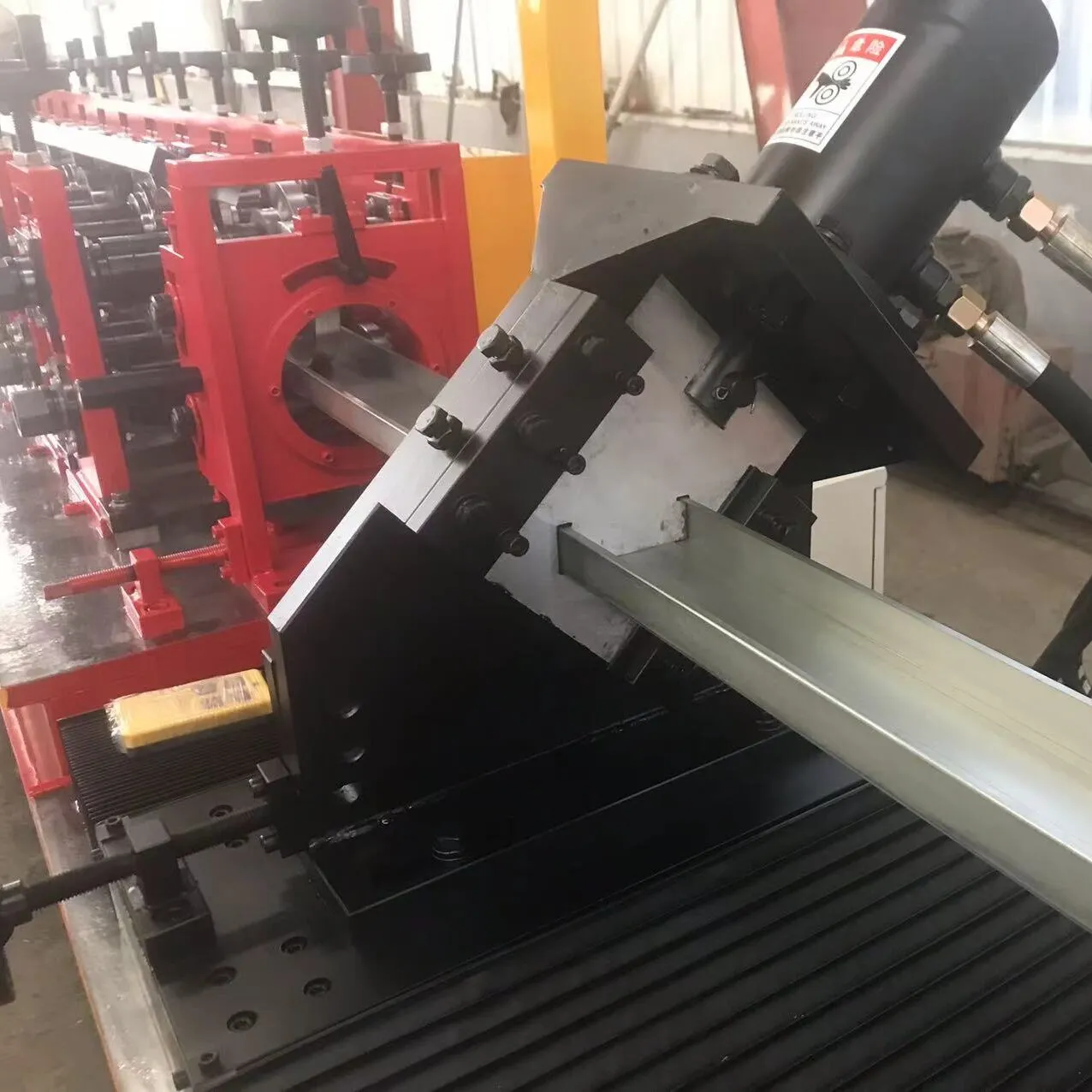

12.Hydraulic servo semita cutting

|

|

|

Imperium systema

It adopts PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

|

|

HYDRAULICUS station

Vis motoris stationis hydraulicae: potentia est 7.5Kw, et statio hydraulicae systematis secans agit.

|

|

|

Servo inuestigandum systematis sectionis

1.Tolerance longitudinis: +/- 1.5mm

2.Material of ferrum: CR12 cum calor curatio

3.Length mensuræ: Lorem longitudinem mensurae

4.Control: ab occasu in PLC systema

|