|

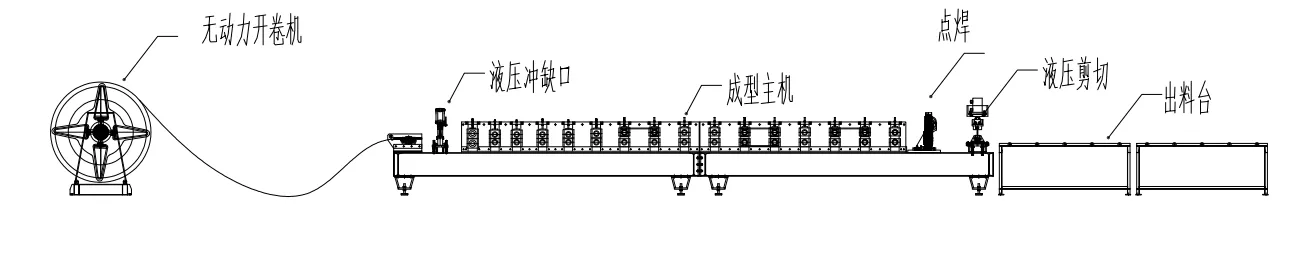

Decoiler

- Uncoiler: passivum unwinding, manual tensis

- Facultatem oneris afferens uncoiler: 5T

- Inner diameter of uncoiling machine: φ508mm

- Rolling range: φ460-530mm

- Rolling width: ≤500

|

|

Ratio dirigens

Statutum est in principio militiae adiuvare operantem recte aptare directionem limbi tabulae. In dextra parte manus rotae accommodare potes, et numerus pascendi monstratur.

|

|

|

Aequandi ratio

1.Diameter of leveling shaft: Φ80 (Harbin Bearing)

2. Materia vectis exaequationis: 40Cr exstingui et temperati (HB220-260)

3.Surface curatio methodi aequandi hastile: super-finiens post altum frequentiam exstinguendi, chromium durum curationis plating

4. Methodus componit medium inter superiores et inferiores scutulis: Turbine elevator commensurationem

|

|

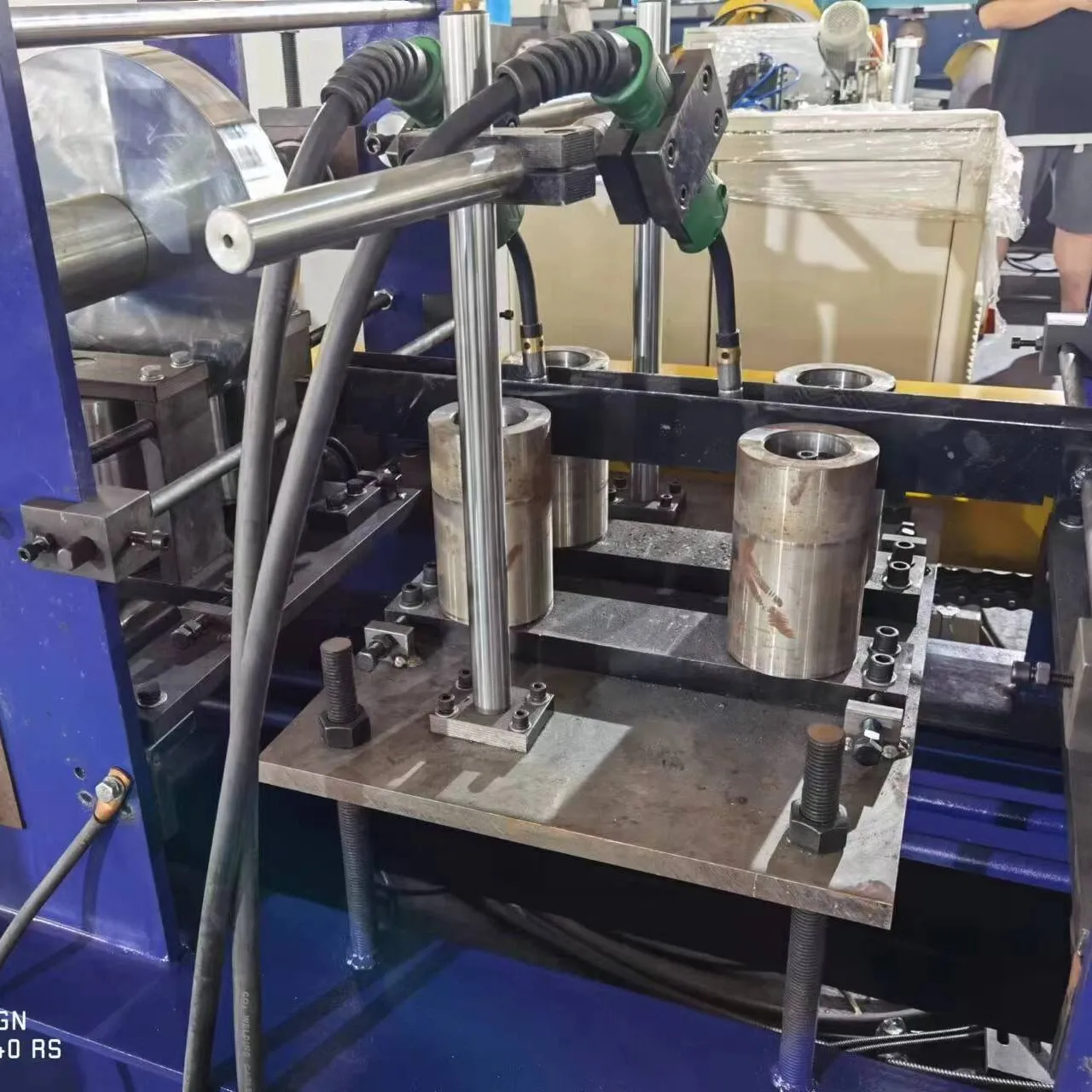

HYDRAULICUS punching

|

|

|

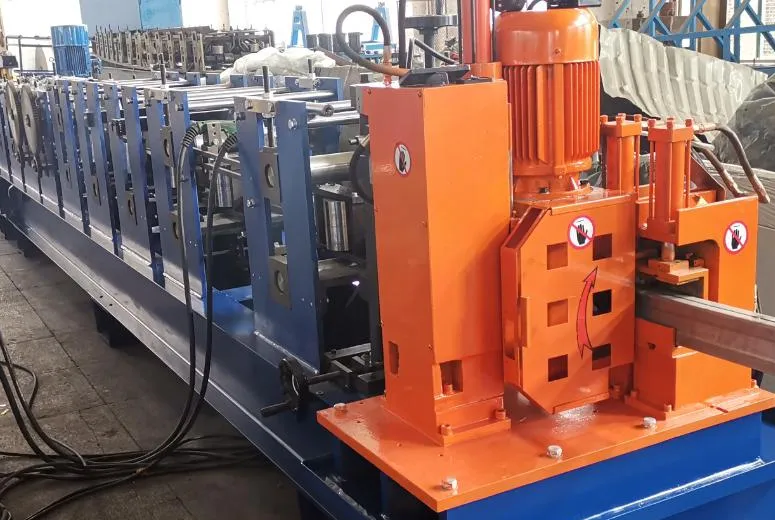

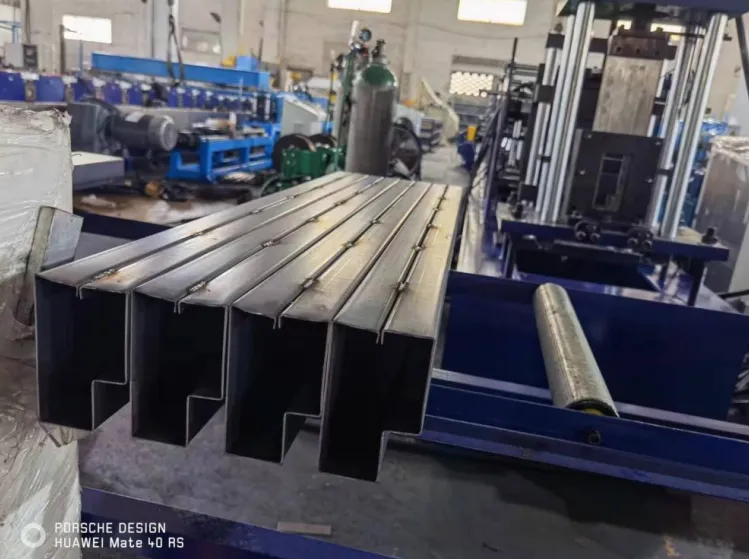

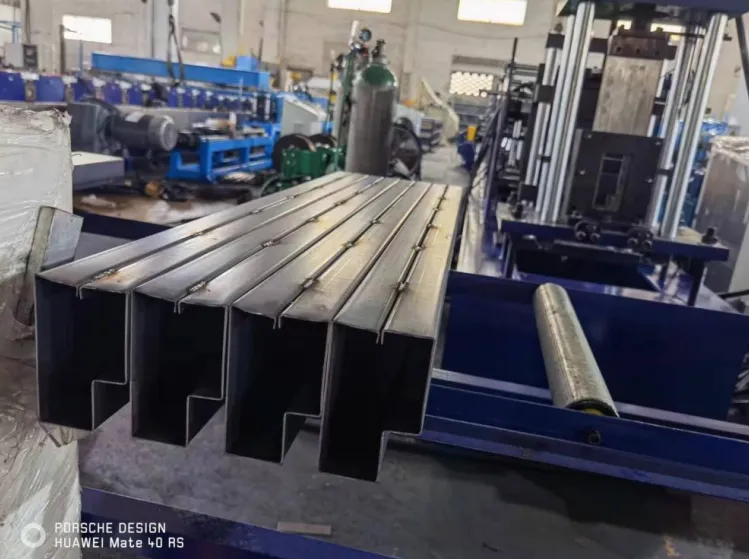

Roll machinatio

- Materia crassitudo range: 2 mm

- Praecipua motor potentia: 22 kw

- Transversus motor:2*0,75 kw

- 4. Volo: 3-5m/min

- 5. Quantitas scutulis: 26 scutulis

- Materiam scutulis: XLV # cum chromed

- 7. Telum Material et diameter: 80mm, materia est 45# malleoli chalybe

- 8. corpus machinae: 350H

- 9.Tolerance: 10m+-1.5mm

- Via Coegi: Chain

- Imperium systema: PLC

- 12.Material of cutter blade: Cr12 ferrum fingunt cum restincto curatione 58-62℃

- 1Voltage: 380V/3Phase/50HZ

|

|

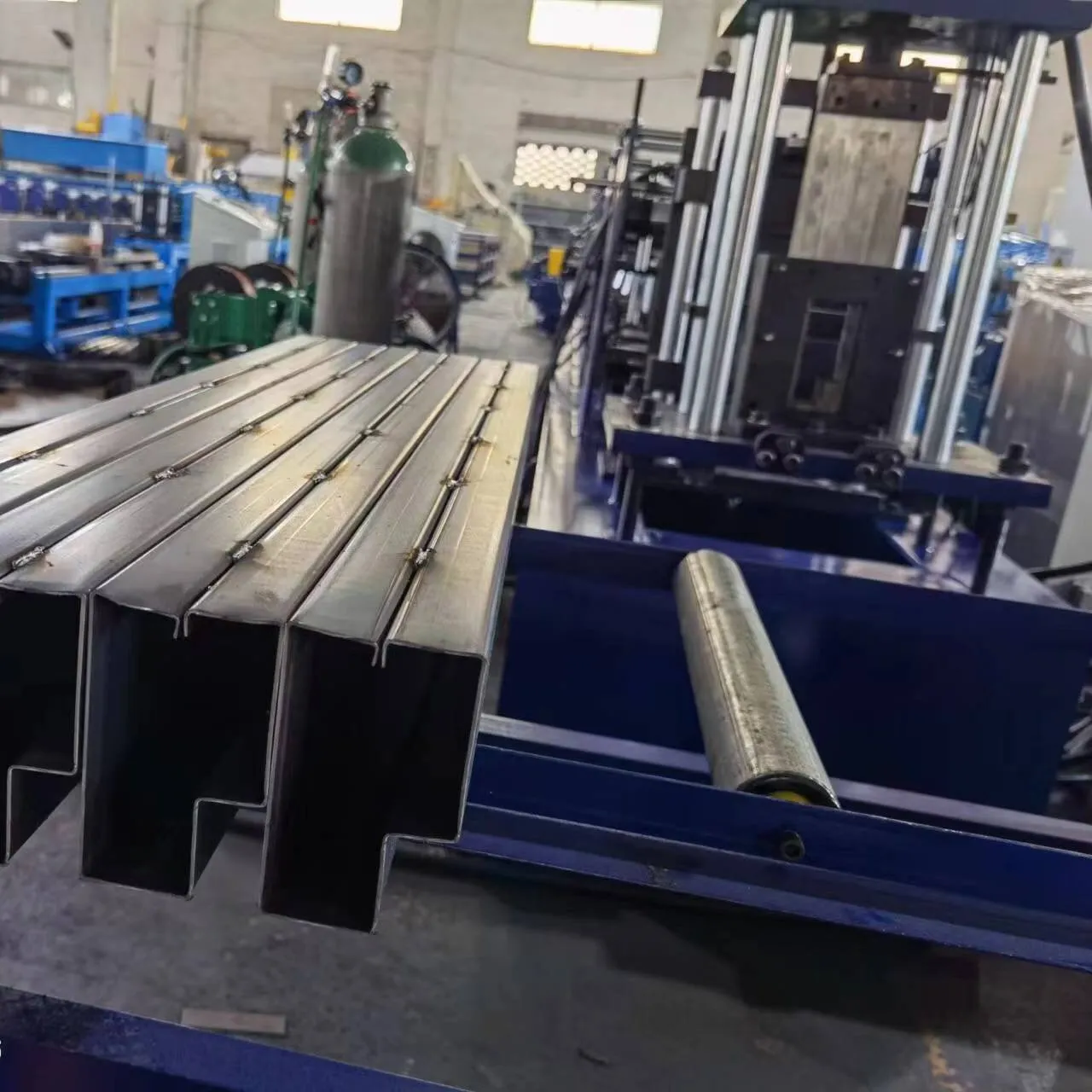

Machina welding

2 machinis glutino, macula glutino

|

|

|

Hydraulica sectione

Secans hydraulica, omnes dimensiones secans cum uno par cultellorum

Hydraulica statione notam: Wuxi Wansheng

Motor hydraulicus: 5.5KW

Hydraulica statione cum aeris refrigerationem

|

|

Accipiens mensam

2000mm* 2 Simplex et impotens (ferro angularis glutino, tympano custardo)

|

|

|

PLC Control system

1.Inverter: Anchuan (Iaponia)

2.PLC: Siemens

3.Computer operating panel: MCGS

4.Coder: Omron / Oceani Optical

5.Voltage; 380V, 50Hz, 3PH.

|