|

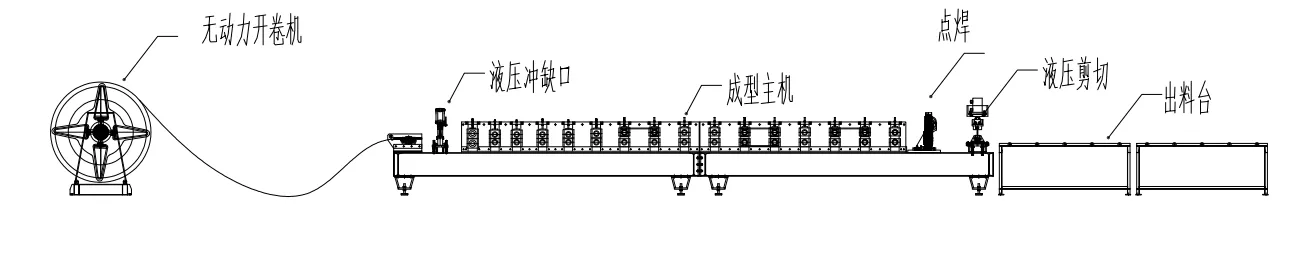

Decoiler

- Uncoiler: passive unwinding, manual tightening

- Load-bearing capacity of uncoiler: 5T

- Inner diameter of uncoiling machine: φ508mm

- Rolling range: φ460-530mm

- Rolling width: ≤500

|

|

Guiding system

It is set at the beginning of the host to help the operator correctly adjust the direction of the inlet board. You can adjust the left and right side by hand wheels, and the number of feed is displayed.

|

|

|

Leveling system

1.Diameter of leveling shaft: Φ80 (Harbin Bearing)

2.Material of leveling shaft: 40Cr quenched and tempered (HB220-260)

3.Surface treatment method of leveling shaft: super-finishing after high-frequency quenching, hard chromium plating treatment

4.The method of adjusting the gap between the upper and lower rollers: turbine elevator adjustment

|

|

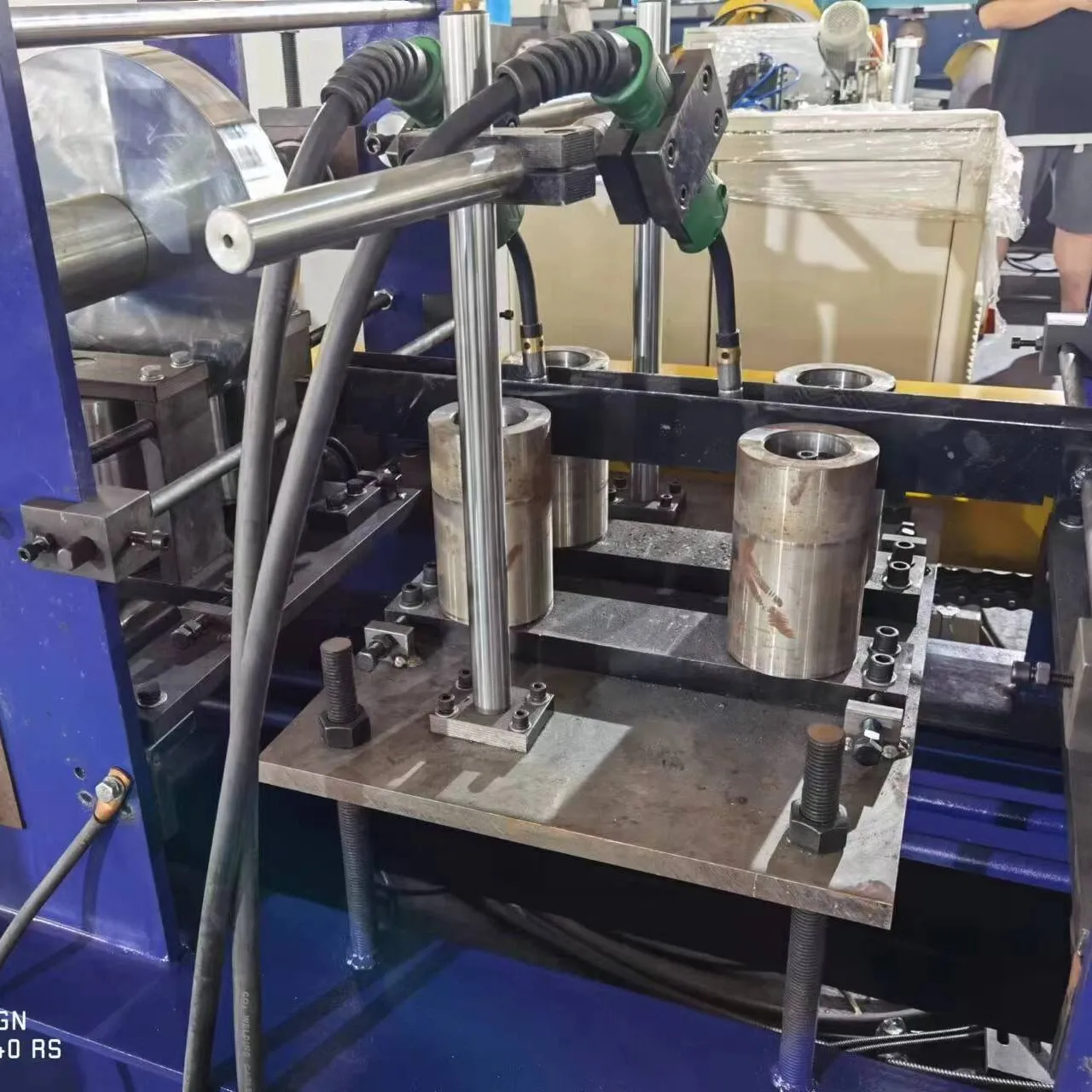

Hydraulic punching

|

|

|

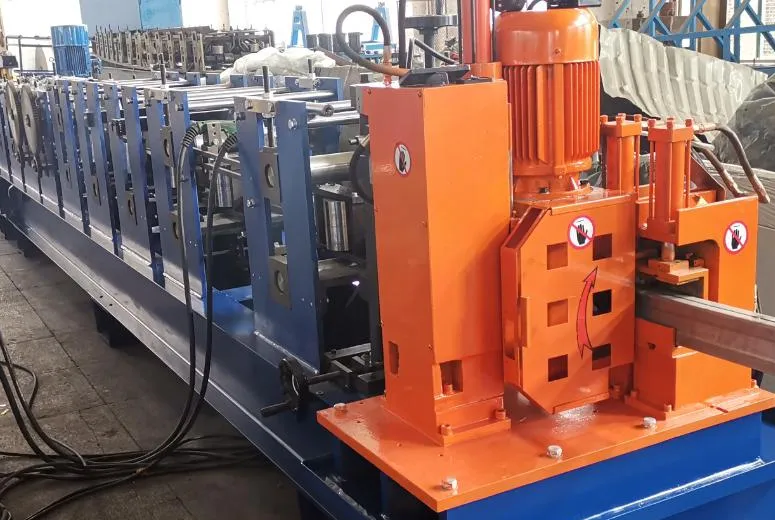

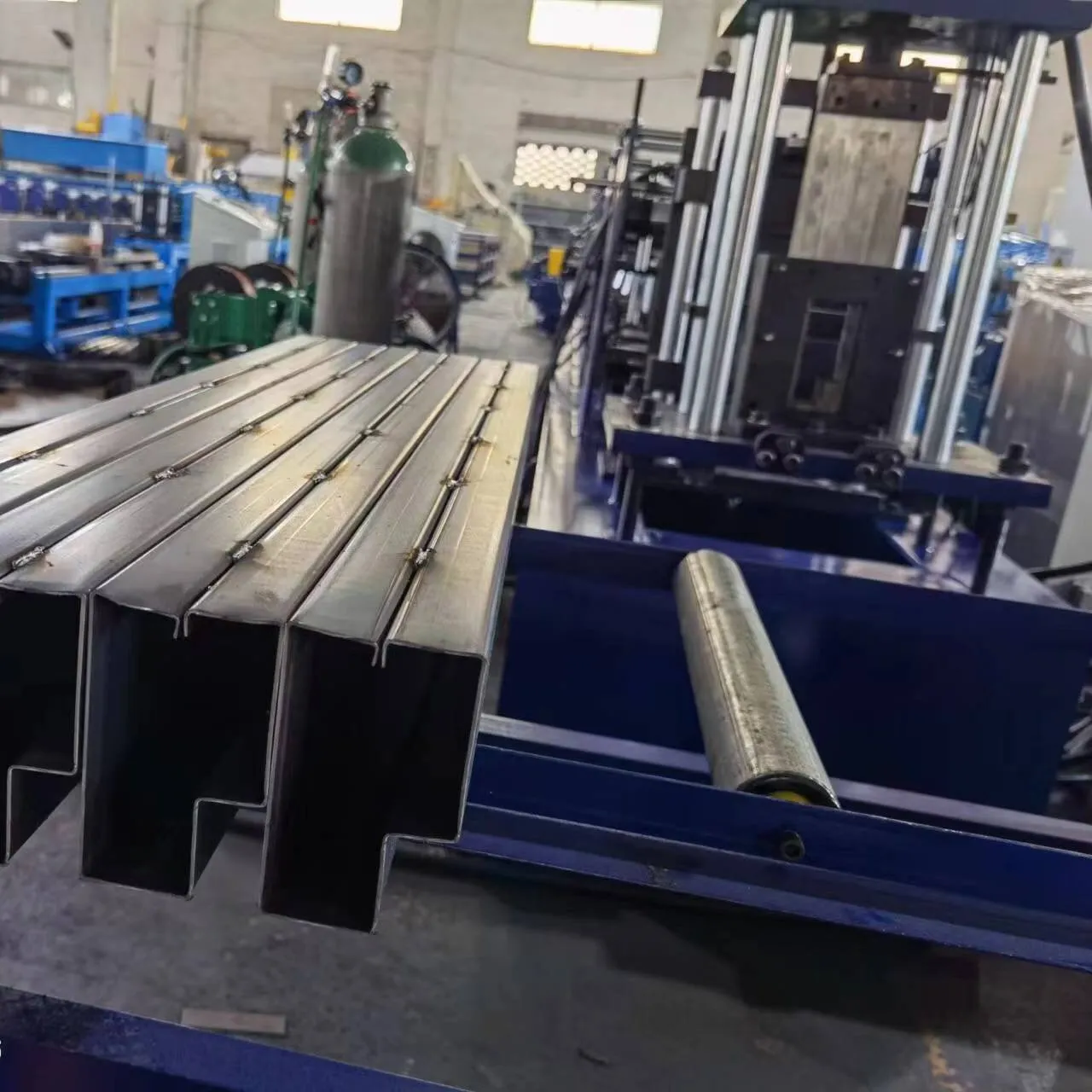

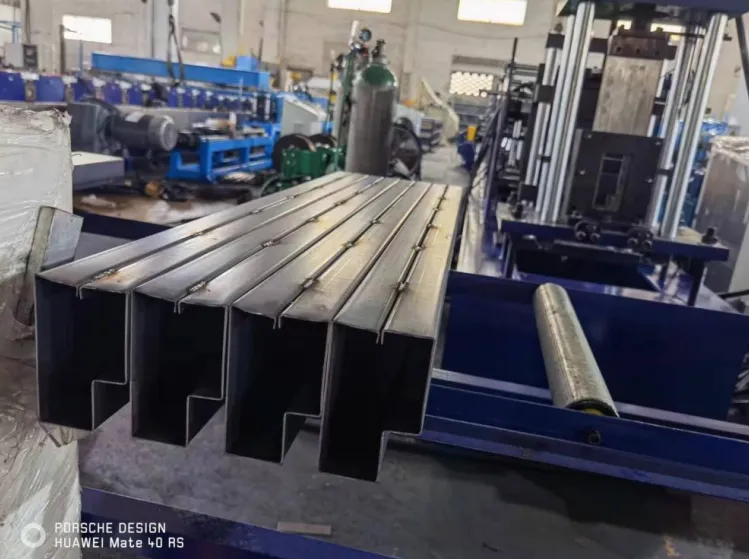

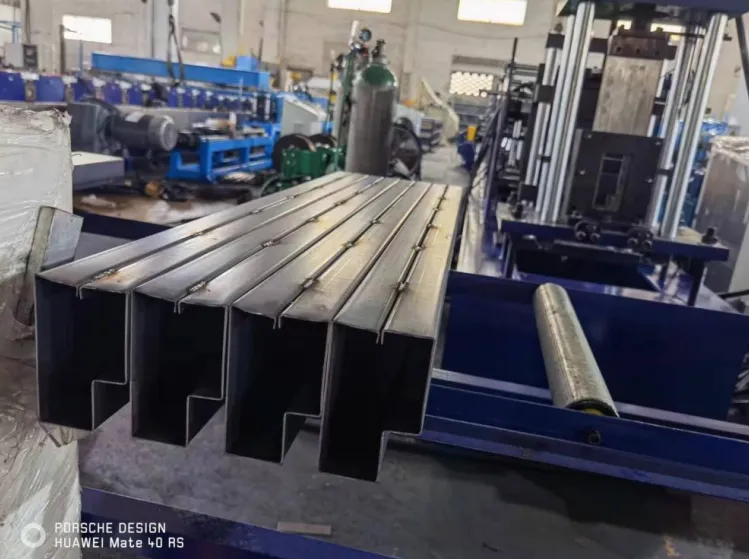

Roll forming machine

- Material thickness range:2 mm

- Main motor power:22 kw

- Transverse motor:2*0.75 kw

- 4. Speed:3-5m/min

- 5. Quantity of rollers:26 rollers

- Material of rollers: 45# with chromed

- 7. Shaft Material and diameter: ¢80mm, material is 45# forge steel

- 8.The body of machine: 350H

- 9.Tolerance: 10m+-1.5mm

- Way Of Drive: Chain

- Control system: PLC

- 12.Material of cutter blade: Cr12 mould steel with quenched treatment 58-62℃

- 1Voltage: 380V/3Phase/50HZ

|

|

Welding machine

2 welding machines, spot welding

|

|

|

Hydraulic cutting

Hydraulic cutting, cutting all dimensions with one pair of knives

Hydraulic station brand: Wuxi Wansheng

Hydraulic motor: 5.5KW

Hydraulic station with air cooling

|

|

Receiving table

2000mm*2 Simple and powerless (corner steel welding, drum custard)

|

|

|

PLC Control system

1.Inverter: Anchuan (Japan)

2.PLC: Siemens

3.Computer operating panel: MCGS

4.Coder: Omron/Optical Ocean

5.Voltage; 380V, 50Hz, 3PH (can be according to customer requirements)

|