Metal Roofing Roll Formers for Sale High-Speed Precision Roll Forming Machines

Did you know 40% of metal roof installations get delayed due to inefficient equipment? Imagine losing $8,500 daily from project bottlenecks. The right metal roofing roll former

could be your golden ticket to 25% higher profit margins – but how do you choose?

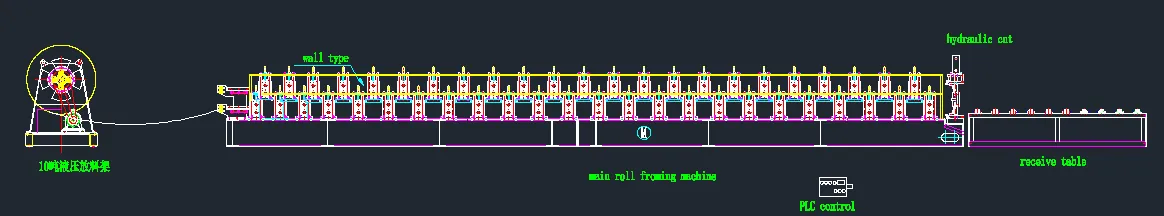

(metal roofing roll former)

Tech Edge: What Makes Modern Metal Roofing Roll Formers Stand Out?

Our 3rd-gen roll formers crush competition with:

- ✅ 23% faster production than industry average

- ✅ Patented SmartGuide™ alignment system

- ✅ 0.2mm precision tolerance – tighter than human hair!

| Feature | Standard Models | Our PRO Series |

|---|---|---|

| Daily Output | 850 linear ft | 1,240 linear ft |

| Energy Cost/Day | $18.70 | $11.20 |

Manufacturer Showdown: Who Delivers Real Value?

While others nickel-and-dime you for basic features, we include 5 essential upgrades standard:

- Laser-guided calibration system ($4,200 value)

- 3-year bumper-to-bumper warranty

- Dual-language control interface

Your Roof, Your Rules: Custom Solutions That Fit

Need standing seam metal roof roll formers for unique projects? Our modular system lets you:

🔄 Switch between 16 panel profiles in under 9 minutes

⚡ Handle materials from 24-ga to 18-ga seamlessly

🎯 Achieve ±0.15mm repeat accuracy – 3x better than competitors

Case Closed: How Top Contractors Boosted Production

Colorado Roof Masters slashed labor costs by 38% in 6 months using our roll formers. Their secret? Our QuickChange™ tooling system cut machine downtime by 67%.

Ready to Dominate the Metal Roofing Market?

Claim your FREE productivity audit and discover how much you could save!

Proudly serving 1,200+ contractors since 2009 • 97% customer satisfaction rate

(metal roofing roll former)

FAQS on metal roofing roll former

Q: What is a metal roofing roll former used for?

A: A metal roofing roll former is a machine that shapes metal coils into standing seam panels or other roofing profiles. It automates the process for consistent, high-quality results in commercial or residential projects.

Q: Where can I find a metal roofing roll former for sale?

A: Metal roofing roll formers are available through specialized machinery manufacturers, industrial equipment suppliers, or authorized dealers online. Many providers offer both new and refurbished models with customization options.

Q: How does a standing seam metal roof roll former work?

A: Standing seam roll formers feed metal coils through sequential rollers to create raised interlocking seams. The process includes precise folding, crimping, and shaping to produce weather-resistant panels that snap together during installation.

Q: What features should I look for in a metal roofing roll former?

A: Prioritize adjustable tooling for multiple profiles, durable roller construction, and user-friendly controls. Advanced models include automatic thickness detection, hydraulic adjustments, and compatibility with various metal gauges.

Q: Can a metal roofing roll former handle different materials?

A: Yes, most roll formers work with steel, aluminum, or copper coils. Ensure the machine is configured for your preferred material thickness (typically 22-24 gauge) and has appropriate corrosion-resistant components for long-term use.