Affordable Roof Sheet Rolling Machine Prices High-Quality Solutions

- Overview of Roof Sheet Rolling Machines

- Cost Efficiency and Market Data Insights

- Technological Superiority in Modern Designs

- Competitor Analysis: Price vs. Performance

- Tailored Solutions for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Final Recommendations for Optimal Investment

(roof sheet rolling machine price)

Understanding Roof Sheet Rolling Machine Price Dynamics

Roof sheet rolling machines are critical for producing durable corrugated roofing materials. The price of these machines varies based on automation levels, material compatibility, and production capacity. Manufacturers often balance affordability with advanced features like hydraulic control systems or CNC integration. For businesses, evaluating the roof sheet rolling machine price

involves analyzing long-term ROI against upfront costs, especially when upgrading from manual to semi-automatic or fully automatic models.

Cost Efficiency and Market Data Insights

Recent industry reports indicate a 12-18% annual growth in demand for roofing machinery, driven by construction booms in emerging economies. A typical roof sheet rolling machine priced at $45,000 can reduce labor costs by 20% and increase output by 35% compared to manual alternatives. Below is a comparison of operational metrics:

| Metric | Manual Machine | Semi-Auto | Full-Auto |

|---|---|---|---|

| Output (sheets/day) | 120-150 | 300-400 | 600-800 |

| Labor Required | 4-5 workers | 2 workers | 1 operator |

| Error Rate | 8-10% | 3-4% | <1% |

Technological Superiority in Modern Designs

Leading models now incorporate laser-guided alignment and IoT-enabled predictive maintenance. For instance, Company X’s roof sheet rolling machine reduces material waste by 15% through real-time thickness calibration, while Company Y’s AI-driven system optimizes coil feeding sequences to save 9% energy per cycle.

Competitor Analysis: Price vs. Performance

| Brand | Price Range | Max Speed (m/min) | Customization | Warranty |

|---|---|---|---|---|

| AlphaRoll | $38,000-$52,000 | 25 | Tooling swaps | 3 years |

| BetaForm | $47,500-$68,000 | 32 | PLC programming | 5 years |

| GammaBend | $41,200-$58,000 | 28 | Multi-profile kits | 4 years |

BetaForm’s premium models justify their corrugated roof sheet machine price with 10-year lifespans, whereas GammaBend offers mid-range versatility for SMEs.

Tailored Solutions for Diverse Industrial Needs

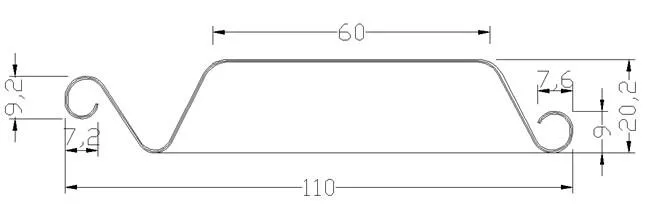

Vendors provide modular configurations: basic models ($28,000-$35,000) handle 0.3-0.7mm GI sheets, while heavy-duty versions ($55,000+) process 1.2mm stainless steel. Custom software add-ons like PRO-ROLL 3.0 enable profile presets for trapezoidal, tile, or concealed-fastener designs.

Real-World Applications and Case Studies

A Southeast Asian contractor reduced project timelines by 40% using roof sheet rolling machines to prefabricate 12,000㎡ of roofing daily. Another case in Germany saw a 22% reduction in scrap metal through precision servo-controlled roll forming.

Final Recommendations for Roof Sheet Rolling Machine Price Evaluation

Prioritize suppliers offering free technical training and localized spare parts networks. For budgets under $40,000, focus on semi-automatic machines with 350+ sheet/day capacity. High-volume manufacturers should consider $60,000+ automated systems with dual-decibel operation below 75dB for urban compliance.

(roof sheet rolling machine price)

FAQS on roof sheet rolling machine price

Q: What factors influence the price of a roof sheet rolling machine?

A: The price depends on automation level, production capacity, material thickness compatibility, and brand reputation. Advanced features like CNC controls or multi-layer designs increase costs.

Q: How much does a basic roof sheet rolling machine cost?

A: Manual or semi-automatic models start around $5,000-$15,000. Prices rise significantly for fully automated systems, which can exceed $50,000.

Q: Is a corrugated roof sheet machine price different from standard models?

A: Yes, machines specialized for corrugated patterns often cost 10%-20% more due to customized rollers and complex forming mechanisms.

Q: Can I get a used roof sheet rolling machine at a lower price?

A: Used machines typically cost 30%-50% less than new ones, but maintenance history and part availability should be verified before purchase.

Q: Why do prices vary between roof sheet rolling machine suppliers?

A: Variations stem from manufacturing standards, after-sales support, shipping costs, and included features like warranty or training programs.