The Angle Light Keel Roll Forming Machine stands out with its ability to produce multiple sizes of angle light keels, making it an incredibly versatile addition to your production line. Whether you need standard sizes or custom dimensions, this machine can be easily adjusted to accommodate your specific needs, allowing for greater flexibility in your operations.

Equipped with advanced technology, the machine operates at impressive speeds, significantly reducing production time and increasing efficiency. This means you can fulfill larger orders in shorter timeframes, giving you a competitive edge in the market. The precision engineering of the Angle Light Keel Roll Forming Machine ensures that every product meets the highest standards of quality, with consistent dimensions and finishes that enhance the overall integrity of your construction projects.

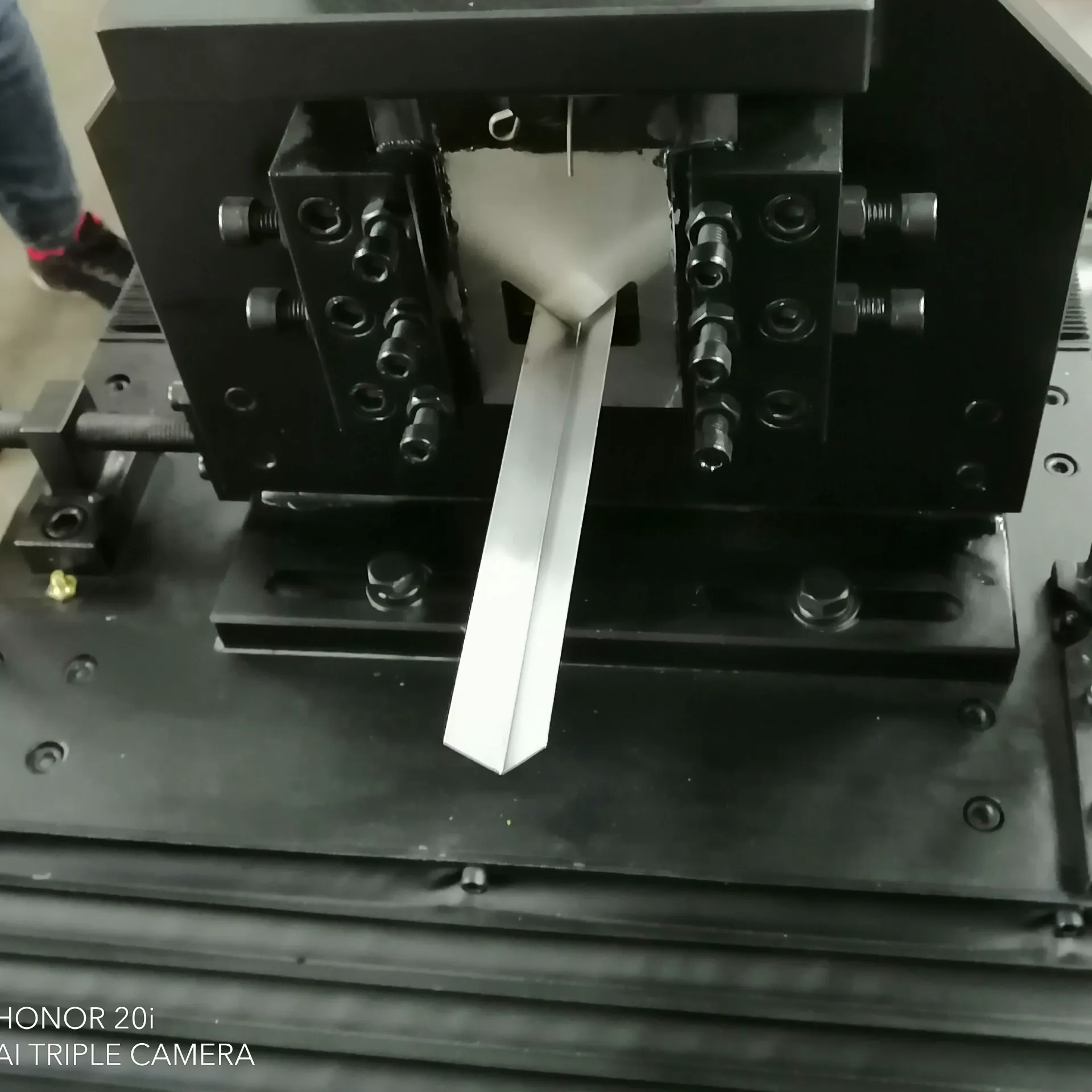

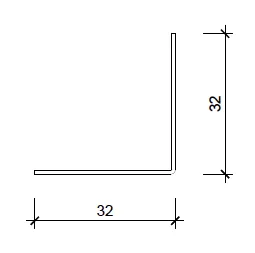

Drawings

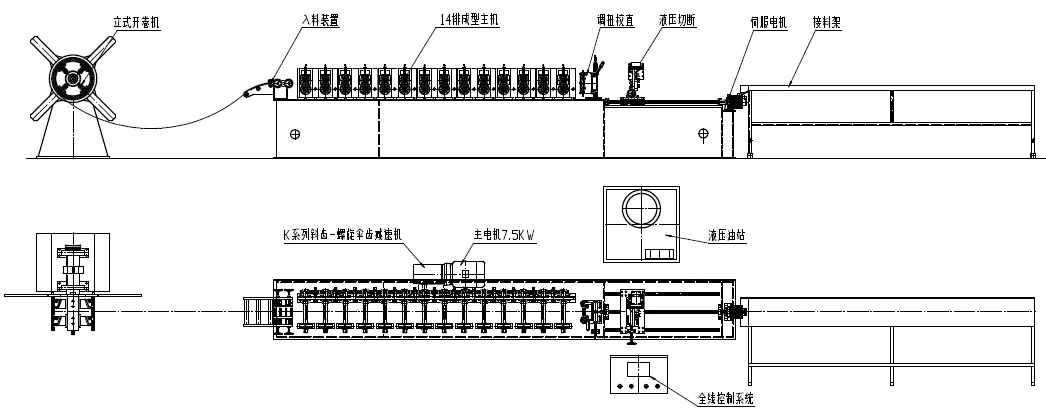

Processes and components

| Manuel decoiler | x 1 set |

| Guiding machine | x 1 set |

| Main roll forming machine | x 1 set |

| Servo tracking cutting system | x 1 set |

| Hydraulic station | x 1 set |

| PLC Control system | x 1 set |

| Run-out table (3M*2) | x 1 set |

Working Process

Technical Parameters

|

Decoiler 1) Capacity: 3 tons 2). Manual decoiler |

|

|

Material guiding Input width adjustable |

|

Roll forming machine Matching material: Galvanized or PPGI Material thickness range: 0.55-0.75mm Forming speed: 0-40m/min 4. Main power: 0KW ,Hydraulic station:3kw 5. Quantity of roller:8 6. Shaft Material and diameter: ¢40mm, material is 45CR 7.The way of driving:Gear 8. Controlling system: PLC 9. Voltage: 220V/ 3phase/ 60 Hz 10.Material of forming rollers: Cr12,HRC58-62 11.Material of cutter blade: Cr12 mould steel with quenched treatment,HRC 58-62℃ 12.Servo tracking cutting

|

|

|

Control system It adopts PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. |

|

Hydraulic station Motor power of hydraulic station: the power is 5.5Kw, and the hydraulic station drives the cutting system. |

|

|

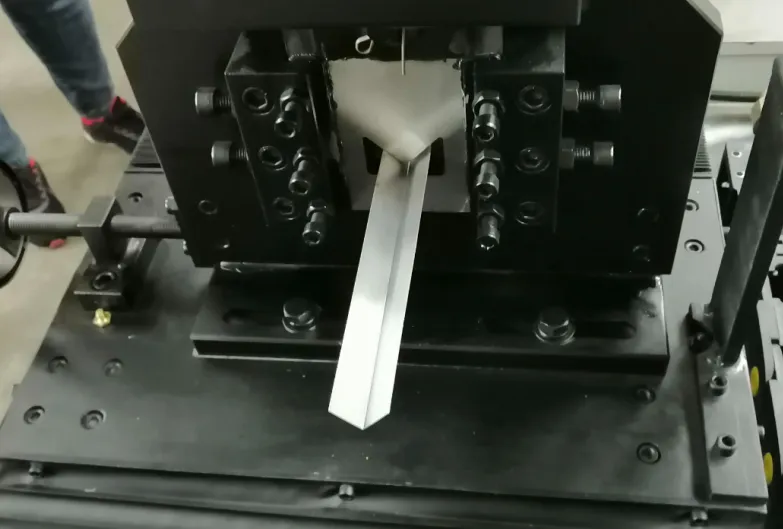

Servo track cutting system 1.Tolerance of length: +/- 1.5mm 2.Material of blade: CR12 with heat treatment 3.Length measuring: Automatic length measuring 4.Control: by setting on the PLC system |

More pictures