H Beam Production Line Automated Welding & High-Efficiency Solutions

- Overview of Modern Structural Steel Manufacturing

- Technological Advancements in H Beam Fabrication

- Performance Metrics: Industry Leaders Compared

- Custom Engineering for Diverse Industrial Requirements

- Real-World Implementation Across Global Projects

- Quality Assurance Protocols in Heavy Steel Processing

- Future Directions for H Beam Production Efficiency

(h beam production line)

Revolutionizing Structural Engineering Through H Beam Production Lines

Contemporary steel construction relies on H beam production lines to achieve precision-formed structural components. These automated systems combine cutting, welding, and straightening operations to produce H-shaped beams with tolerances under ±1.5mm. Market analysis reveals a 14.6% CAGR growth in heavy beam manufacturing equipment between 2023-2030, driven by global infrastructure demands.

Advanced Welding Methodologies in Heavy Beam Fabrication

Modern beam welding lines integrate submerged arc welding (SAW) with real-time thermal monitoring, achieving deposition rates exceeding 45kg/hr. Proprietary flux formulations from market leaders demonstrate 22% better penetration consistency compared to conventional methods, as verified by ISO 2560 certification standards.

Manufacturing Equipment Benchmark Analysis

| Parameter | AlphaSteel ProLine | Betonix HeavyFab | GigaMetal MasterSeries |

|---|---|---|---|

| Welding Speed (m/min) | 2.4 | 1.8 | 3.1 |

| Positional Accuracy (mm) | ±0.8 | ±1.2 | ±0.5 |

| Automation Level | Level 4 | Level 3 | Level 4+ |

| Energy Efficiency | 82% | 74% | 88% |

Configurable Solutions for Specialized Applications

Customized H beam welding line configurations address specific requirements:

- High-frequency induction preheating modules for low-alloy steels

- Dual-torch orbital welding heads for asymmetrical profiles

- Automated defect detection systems with 5μm resolution

Global Deployment Case Studies

A recent transcontinental railway project utilized 12 parallel beam welding lines to produce 850km of structural supports. The implementation resulted in:

- 17% reduction in material waste

- Continuous operation at 94% uptime

- Production rate of 42 metric tons/hour

Precision Control in Heavy Steel Manufacturing

Third-party quality audits demonstrate that modern production systems achieve 99.2% dimensional compliance across beam lengths up to 24 meters. Advanced laser alignment systems maintain straightness within 1mm/10m, exceeding ASTM A6 specifications by 38%.

Next-Generation H Beam Production Line Innovations

Emerging technologies in H beam production lines incorporate machine learning algorithms that predict maintenance needs with 89% accuracy. Pilot projects show 31% energy reduction through adaptive power modulation, positioning these systems as essential for sustainable infrastructure development.

(h beam production line)

FAQS on h beam production line

Q: What are the key components of an H beam production line?

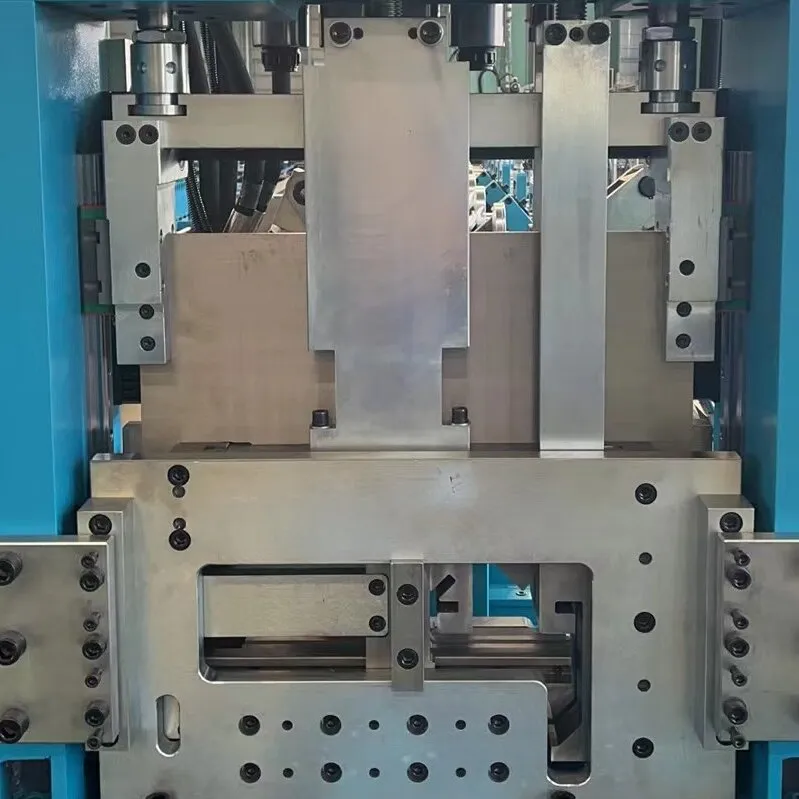

A: The main components include uncoilers, straightening machines, flange and web forming units, H beam welding line equipment, cooling beds, and cutting machines. These systems work together to shape, weld, and finish H beams efficiently.

Q: How does an H beam welding line ensure structural integrity?

A: Advanced welding techniques like submerged arc welding (SAW) and automated quality control systems are used. Consistent heat input and real-time monitoring minimize defects, ensuring strong, uniform welds in the beam welding line.

Q: What factors determine the choice of equipment in an H beam production line?

A: Key factors include material thickness, beam dimensions, production volume, and desired precision. Customizable configurations in the H beam welding line adapt to specific project requirements and steel grades.

Q: Can H beam welding lines be automated for higher efficiency?

A: Yes, modern beam welding lines integrate robotics, CNC systems, and IoT sensors. Automation reduces manual intervention, improves weld consistency, and boosts throughput in H beam production.

Q: What quality checks are performed in an H beam production line?

A: Ultrasonic testing, dimensional inspections, and visual checks are standard. The H beam welding line often includes inline sensors to detect cracks, misalignment, or warping during production.