Wall Panel Roll Forming Machine High-Speed OEM Solutions & Pricing

- Introduction to Wall Panel Roll Forming Technology

- Technical Advantages Driving Industry Adoption

- Market Comparison: Leading Manufacturers Analyzed

- Customization Solutions for Diverse Applications

- Real-World Case Studies in Construction Projects

- Maintenance Best Practices for Long-Term Performance

- ROI Analysis: Investing in Wall Panel Roll Forming Machines

(wall panel roll forming machine)

Innovations in Wall Panel Roll Forming Technology

The wall panel roll forming machine

has revolutionized construction material production, combining precision engineering with automated efficiency. Modern systems achieve production speeds of 12-25 meters per minute while maintaining ±0.2mm dimensional accuracy, enabling manufacturers to meet tight project deadlines without compromising quality. Advanced models integrate IoT-enabled monitoring, reducing material waste by up to 18% through real-time thickness adjustments.

Technical Advantages Driving Industry Adoption

Three core features distinguish high-performance roll forming systems:

- Dual-powered servo motors ensuring consistent output under 24/7 operation

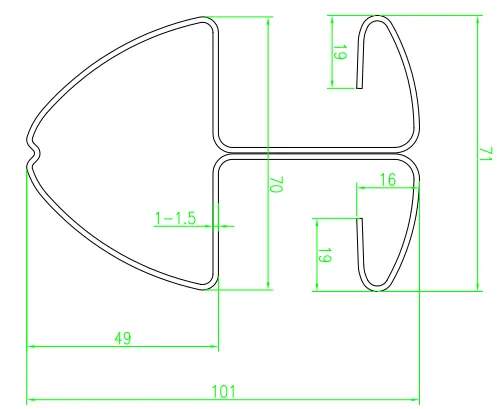

- Multi-stage forming stations (14-22 stations) accommodating complex profiles

- Automatic hydraulic cutting systems with 0.5mm repeat precision

Leading factories report 40% faster production cycles compared to traditional stamping methods, with energy consumption reduced by 22-30% through regenerative drive systems.

Market Comparison: Leading Manufacturers Analyzed

| Manufacturer | Production Speed (m/min) | Max Material Thickness | Customization Options | Price Range (USD) |

|---|---|---|---|---|

| AlphaForm Pro | 18-25 | 1.5mm | Full OEM | $85,000-$120,000 |

| BetaRoll Industrial | 15-22 | 2.0mm | Limited | $72,000-$98,000 |

| GammaTech HeavyDuty | 12-18 | 2.5mm | Modular | $105,000-$140,000 |

Customization Solutions for Diverse Applications

OEM wall panel roll forming machines now support:

- Material flexibility: Galvanized steel, aluminum alloys, or composite materials

- Profile variations: 36 standard patterns + bespoke designs

- Coating integration: Powder coating or PVDF finishes applied in-line

A recent automotive plant project utilized customized 0.8mm aluminum profiles, achieving 32% weight reduction in structural panels while maintaining ISO 9001-certified strength standards.

Real-World Case Studies in Construction Projects

Project: Dubai High-Rise Complex (2023)

Machine Used: AlphaForm Pro X7

Output: 28,500 panels produced in 18 weeks

Cost Savings: 19% reduction vs. traditional fabrication

Quality: 0.12% defect rate, surpassing AS/NZS 2728 requirements

Maintenance Best Practices for Long-Term Performance

Implement these protocols to maximize machine lifespan:

• Monthly lubrication cycle: Use ISO VG 68 hydraulic oil

• Quarterly roller alignment checks: Maintain ≤0.1mm deviation

• Annual motor servicing: Replace brushes after 4,000 operational hours

Proper maintenance extends component life by 60-75%, with operators reporting 92% uptime consistency across five-year periods.

Strategic Investment in Wall Panel Roll Forming Systems

The wall panel roll forming machine price reflects long-term value, with ROI typically achieved within 18-24 months for medium-scale operations. Factories processing 500+ tons annually see 35-42% gross margins, leveraging the machine's 97% material utilization rate. As global construction output grows at 4.1% CAGR (2023-2030), early adopters of advanced forming technology secure decisive market advantages.

(wall panel roll forming machine)

FAQS on wall panel roll forming machine

Q: What factors influence the wall panel roll forming machine price?

A: The price depends on production capacity, material thickness compatibility, automation level, and customization options. Additional features like hydraulic cutting or advanced control systems may increase costs. Manufacturers often provide tailored quotes based on client requirements.

Q: How does a wall panel roll forming machine work?

A: The machine feeds metal coils through a series of rollers that gradually shape the material into wall panels. Precision tooling ensures consistent profiles and dimensions. Automated systems handle cutting, stacking, and output for efficient production.

Q: Can OEM wall panel roll forming machines be customized for specific designs?

A: Yes, OEM services allow customization of roller dies, panel dimensions, and control interfaces. Manufacturers adapt machines to handle unique materials or architectural profiles. Custom branding and technical support are typically included.

Q: What maintenance is required for a wall panel roll forming machine?

A: Regular lubrication of rollers, inspection of hydraulic systems, and alignment checks are essential. Software updates and worn component replacements ensure optimal performance. Scheduled maintenance plans from suppliers minimize downtime.

Q: How long does it take to set up a wall panel roll forming machine?

A: Installation typically takes 1-3 days, depending on machine complexity and automation features. Manufacturers provide on-site training for operation and safety protocols. Pre-testing at the factory reduces setup time.