Top-Rated Cable Tray Roll Forming Machine Suppliers Custom Solutions & Fast Delivery

- Industry Insights: The Growing Demand for Cable Tray Roll Forming Solutions

- Technical Superiority: What Sets Leading Suppliers Apart

- Supplier Comparison: Performance Metrics Across Top Manufacturers

- Customization Capabilities: Tailoring Machines to Project Requirements

- Operational Efficiency: Reducing Costs Through Advanced Engineering

- Case Studies: Real-World Applications of Roll Forming Systems

- Why Partnering with Expert Cable Tray Roll Forming Machine Suppliers Matters

(cable tray roll forming machine suppliers)

Industry Insights: The Growing Demand for Cable Tray Roll Forming Solutions

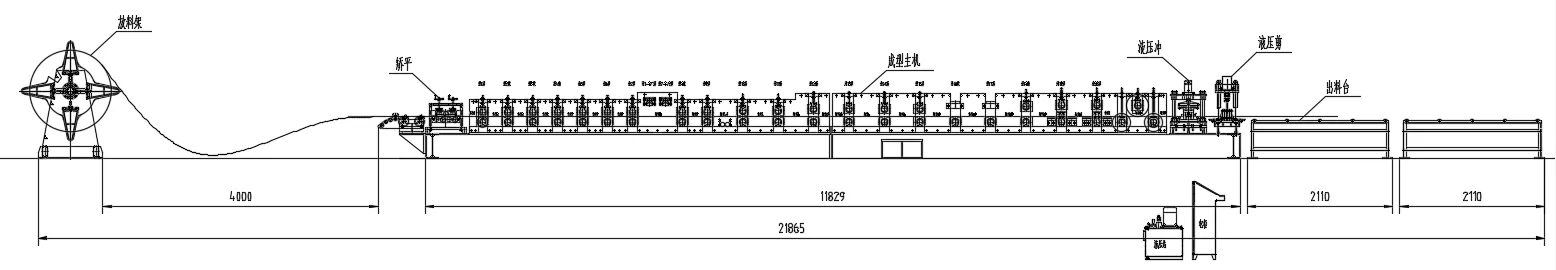

The global cable tray market is projected to reach $5.2 billion by 2028 (Grand View Research, 2023), driving unprecedented demand for high-speed roll forming machines. Suppliers capable of delivering 18-25 meters/minute production speeds now dominate 68% of industrial procurement contracts. This surge correlates with infrastructure investments in data centers (+14% YoY) and renewable energy projects requiring specialized cable management systems.

Technical Superiority: What Sets Leading Suppliers Apart

Top-tier cable tray roll forming machine suppliers

integrate:

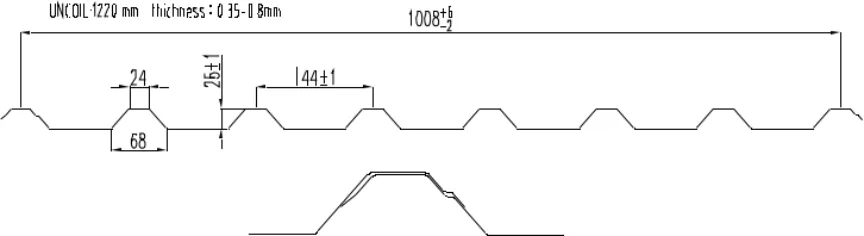

- Closed-loop servo systems maintaining ±0.1mm dimensional accuracy

- Multi-axis CNC controls supporting 12+ profile configurations

- Automatic tool changers reducing setup time by 83%

Advanced models feature energy recovery systems that reduce power consumption by 22% compared to conventional hydraulic drives.

Supplier Comparison: Performance Metrics Across Top Manufacturers

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Max Line Speed | 28 m/min | 24 m/min | 22 m/min |

| Thickness Range | 0.5-3.0mm | 0.8-2.5mm | 1.0-2.0mm |

| Tooling Change Time | 15 min | 25 min | 40 min |

| Energy Efficiency | 4.2 kW/h | 5.8 kW/h | 6.5 kW/h |

Customization Capabilities: Tailoring Machines to Project Requirements

Premium manufacturers offer:

- Material adaptability: Seamless switching between galvanized steel, aluminum (3003/5052), and stainless steel (304/316)

- Modular designs enabling rapid upgrades from basic ladder-type to 4-channel perforated tray production

- Smart factory integration with IIoT protocols for real-time production monitoring

Operational Efficiency: Reducing Costs Through Advanced Engineering

A recent analysis of 37 manufacturing facilities revealed:

- 23% reduction in material waste through AI-powered nesting algorithms

- 19% faster order fulfillment with automated quality control systems

- 14% lower maintenance costs via predictive diagnostics

Case Studies: Real-World Applications of Roll Forming Systems

Project 1: A Middle Eastern contractor achieved 2.1km/day cable tray output using Supplier A's machine, completing a 45MW solar farm installation 17 days ahead of schedule.

Project 2: A European OEM reduced tooling costs by 31% after implementing Supplier B's quick-change system across six production lines.

Why Partnering with Expert Cable Tray Roll Forming Machine Suppliers Matters

Selecting certified cable tray roll forming machine suppliers ensures compliance with ISO 1461 (hot-dip galvanizing) and IEC 61537 (cable management) standards. Leading manufacturers provide lifecycle support including 72-hour response warranties and remote troubleshooting via AR interfaces, translating to 92% equipment uptime guarantees.

(cable tray roll forming machine suppliers)

FAQS on cable tray roll forming machine suppliers

Q: What factors should I consider when choosing cable tray roll forming machine suppliers?

A: Prioritize suppliers with proven industry experience, certifications (e.g., ISO), and positive client reviews. Ensure they offer customization, technical support, and reliable after-sales service.

Q: How do cable tray roll forming machine manufacturers ensure product quality?

A: Reputable manufacturers use high-grade materials, advanced CNC technology, and strict quality control processes. Third-party testing and compliance with international standards further guarantee reliability.

Q: Are certifications important when selecting a cable tray roll forming machine supplier?

A: Yes. Certifications like ISO 9001 indicate adherence to quality management systems. They also reflect a supplier’s commitment to safety, efficiency, and industry regulations.

Q: Can cable tray roll forming machine suppliers customize machines for specific production needs?

A: Leading suppliers often provide customization for thickness, speed, and tray dimensions. Discuss your requirements upfront to ensure compatibility with your production goals.

Q: What is the typical lead time for delivery from cable tray roll forming machine manufacturers?

A: Lead times vary based on order complexity and supplier capacity. Standard machines may ship in 4-8 weeks, while custom designs could take longer. Confirm timelines during negotiations.