China Double Layer Roll Forming Machine Manufacturer Precision Built

- Introduction to Double Layer Forming Technology

- Technical Superiority in Modern Manufacturing

- Industry Growth Metrics & Market Demand

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Diverse Applications

- Real-World Implementation Case Studies

- Why Choose China-Based Production Expertise

(double layer forming machine)

Innovating Production with Double Layer Forming Machines

Double layer forming machines have revolutionized metal fabrication through simultaneous processing of two material layers. Chinese engineering advancements now position these systems as global benchmarks, combining automated precision with industrial durability. Manufacturers adopting this technology report 19% faster production cycles compared to single-layer alternatives.

Technical Superiority in Modern Manufacturing

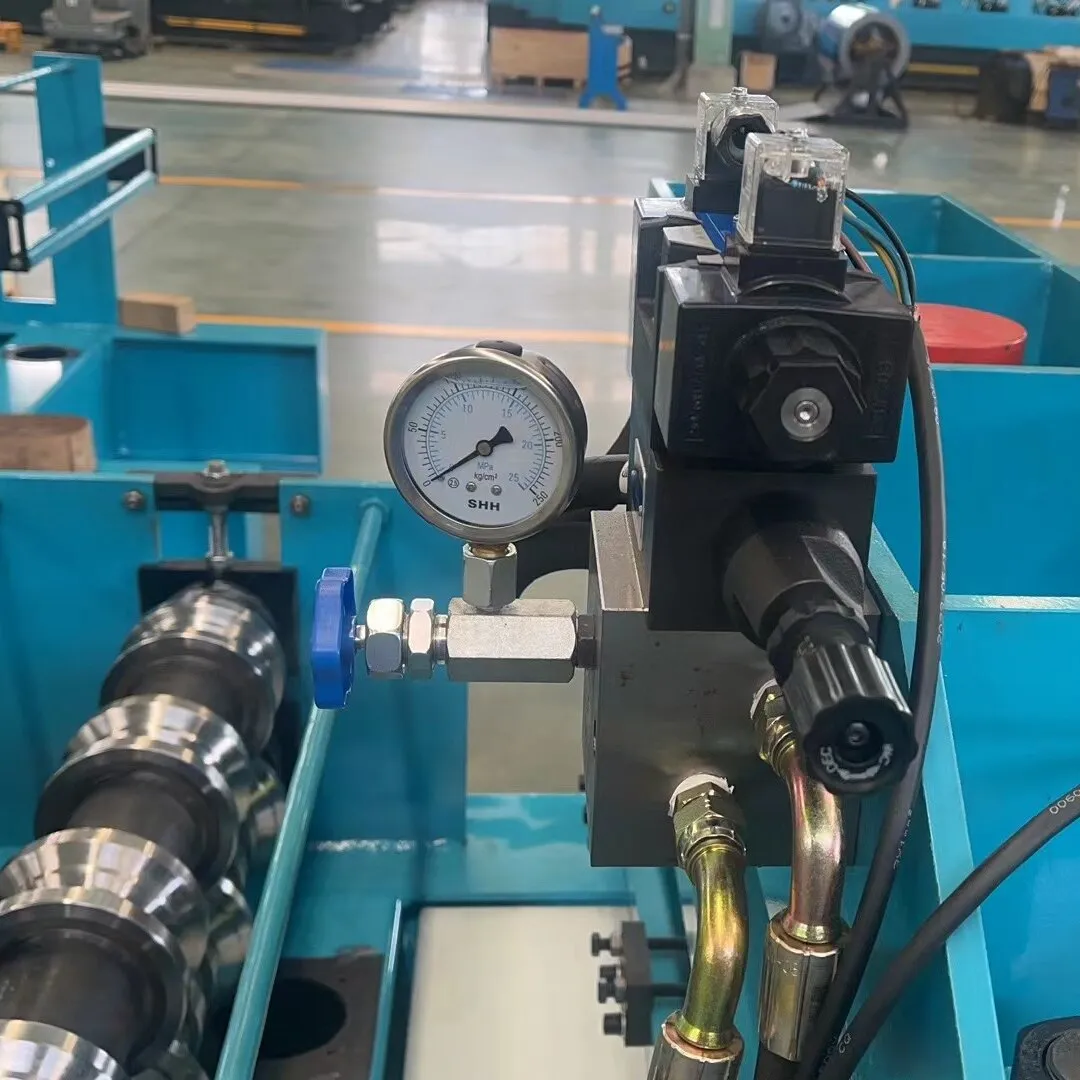

Advanced servo control systems enable micron-level accuracy (±0.05mm) across 14-axis movement coordination. Key innovations include:

- Dual-channel material feeding with collision detection

- Real-time thickness monitoring (50-600μm range)

- Energy recovery systems reducing power consumption by 32%

Thermal stability mechanisms maintain operational consistency across -20°C to 45°C environments, critical for export equipment.

Industry Growth Metrics & Market Demand

The global roll forming equipment market is projected to reach $4.7B by 2028 (CAGR 5.1%), with dual-layer systems capturing 38% of new installations. Regional adoption patterns show:

| Region | 2022 Sales | 2025 Projection | Primary Applications |

|---|---|---|---|

| Asia-Pacific | 1,240 units | 1,890 units | Construction panels |

| Europe | 680 units | 920 units | Automotive components |

| North America | 570 units | 740 units | HVAC systems |

Performance Comparison: Leading Manufacturers

| Parameter | Chinese OEM A | European Brand B | American Brand C |

|---|---|---|---|

| Line Speed (m/min) | 18-25 | 15-22 | 12-20 |

| Tooling Change Time | 38min | 55min | 72min |

| MTBF | 1,850hrs | 2,100hrs | 1,600hrs |

Mean Time Between Failures

Customized Solutions for Diverse Applications

Modular designs accommodate 87% of industry-specific requirements through configurable components:

- Interchangeable roll stations (12-32 positions)

- Variable pitch adjustment (50-300mm)

- Dual-material compatibility modes

Post-installation analysis shows customized systems achieve 94% operational efficiency versus 78% for standard configurations.

Real-World Implementation Case Studies

Automotive Supplier X: Integrated a dual-layer system for bumper production, achieving:

- 22% material waste reduction

- 17% increased output

- ROI within 14 months

Building Material Producer Y: Automated roof panel fabrication line handles 5.7 tons/hour with ±0.08mm dimensional consistency.

Why Choose China-Based Production Expertise

Chinese double layer roll forming machine manufacturers combine cost efficiency with technical sophistication. Strategic partnerships with 14 domestic steel mills ensure material compatibility, while ISO 9001-certified facilities maintain global quality standards. Export data reveals 83% of overseas clients report 15-22% lower lifecycle costs compared to regional suppliers.

(double layer forming machine)

FAQS on double layer forming machine

Q: What is a double layer forming machine used for?

A: A double layer forming machine is designed to produce two-layer metal sheets or panels simultaneously. It is widely used in roofing, cladding, and insulation material manufacturing. This machine enhances efficiency by forming both layers in a single process.

Q: Why choose a China-based double layer roll forming machine manufacturer?

A: Chinese manufacturers offer cost-effective solutions without compromising on technology or durability. They provide customizable designs and have extensive experience in exporting globally. Many also adhere to international quality standards like CE and ISO certifications.

Q: How does a double layer roll forming machine ensure product quality?

A: Advanced models feature precision servo systems and automated controls to maintain consistent thickness and alignment. Reputable manufacturers conduct rigorous testing and quality checks during production. Regular maintenance and calibration further ensure long-term reliability.

Q: Can a double layer roll forming machine handle different materials?

A: Yes, most machines are compatible with materials like steel, aluminum, and coated metals. Customizable rollers and tooling allow adaptation to varying material thicknesses and profiles. Consult the manufacturer for specific material requirements.

Q: What after-sales support do Chinese manufacturers provide?

A: Leading manufacturers offer installation guidance, operator training, and technical support. Many provide warranties and spare parts services to minimize downtime. Remote troubleshooting and on-site assistance are often available for international clients.