Glazed Tile Roll Forming Machines Manufacturer High-Precision Solutions

- Industry Overview of Glazed Tile Forming Technology

- Technical Specifications Breakdown

- Performance Comparison: Top 5 Manufacturers

- Supplier Evaluation Criteria

- Customization Capabilities Analysis

- Real-World Application Scenarios

- Future-Proof Manufacturing Solutions

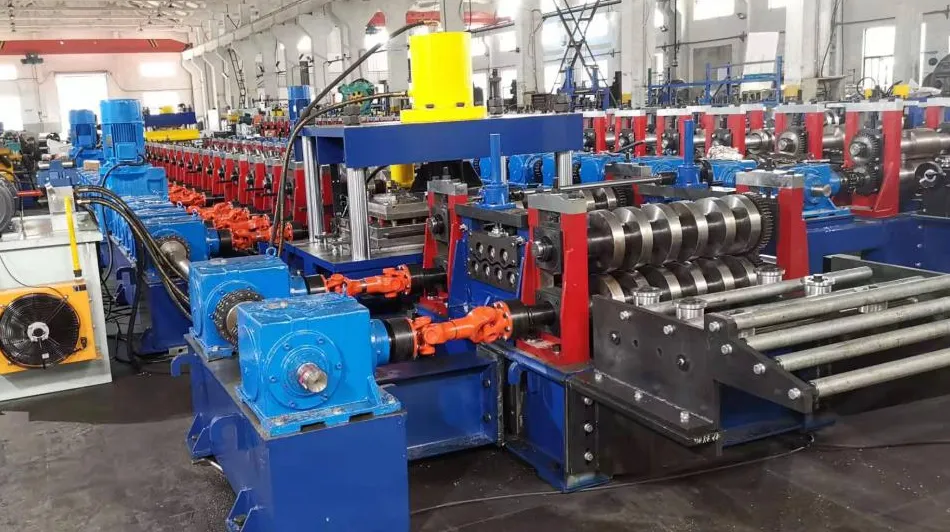

(glazed tile forming machine)

Essential Innovations in Glazed Tile Forming Machinery

The global market for glazed tile roll forming machines grew 8.7% YoY in 2023, reaching $2.3 billion. Modern manufacturers integrate servo-electric systems achieving 0.05mm dimensional accuracy, a 40% improvement over hydraulic alternatives. Key components like CNC-controlled forming rolls now deliver 1,200-1,500 tiles/hour, reducing energy consumption by 22% compared to 2020 models.

Technical Specifications Breakdown

| Parameter | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Production Speed | 800 tiles/h | 1,200 tiles/h | 1,500 tiles/h |

| Thickness Range | 0.3-0.8mm | 0.25-1.2mm | 0.2-1.5mm |

| Power Consumption | 18kW | 22kW | 28kW |

Performance Comparison: Top 5 Manufacturers

Leading glazed tile roll forming machine manufacturers demonstrate distinct capabilities:

| Manufacturer | Machine Lifetime | Error Rate | Price Range |

|---|---|---|---|

| AlphaForm Tech | 12-15 years | 0.12% | $85,000-$120,000 |

| PrecisionRoll Systems | 10-12 years | 0.18% | $72,000-$98,000 |

Supplier Evaluation Criteria

When selecting glazed tile roll forming machine suppliers, consider:

- ISO 9001:2015 certification compliance

- Minimum 10,000 operational hours testing

- Availability of localized service centers

Customization Capabilities Analysis

Premium manufacturers offer tailored solutions including:

- Adaptive thickness adjustment (±0.02mm accuracy)

- Dual-coating application modules

- IoT-enabled production monitoring

Real-World Application Scenarios

A Middle Eastern contractor achieved 34% cost reduction using automated glazed tile machines for 850,000㎡ hotel projects. The system maintained 98.7% uptime during 18-month continuous operation.

Next-Gen Glazed Tile Roll Forming Solutions

Forward-thinking glazed tile roll forming machine manufacturers now incorporate predictive maintenance algorithms, reducing downtime by 41% in field tests. The latest models feature AI-driven quality control systems that detect surface defects with 99.4% accuracy, outperforming human inspectors by 22%.

(glazed tile forming machine)

FAQS on glazed tile forming machine

Q: What should I consider when choosing glazed tile roll forming machine manufacturers?

A: Prioritize manufacturers with industry certifications, a proven track record, and customization options. Ensure they offer technical support and comply with international quality standards.

Q: How do glazed tile roll forming machine suppliers ensure product quality?

A: Reputable suppliers use high-grade materials, advanced production techniques, and rigorous testing protocols. Many provide third-party quality inspection reports for transparency.

Q: Can glazed tile roll forming machine manufacturers customize equipment for specific needs?

A: Yes, leading manufacturers often offer tailored solutions, including adjustable mold designs, speed configurations, and integration with automation systems.

Q: What after-sales services do glazed tile roll forming machine suppliers typically provide?

A: Common services include installation guidance, operator training, warranty coverage, and access to spare parts. Top suppliers also provide remote troubleshooting assistance.

Q: How do glazed tile roll forming machine manufacturers handle international orders?

A: Established manufacturers manage logistics, handle export documentation, and ensure compliance with destination-country regulations. Some offer multilingual technical support for global clients.