High-Efficiency Sheet Metal Roll Forming Machines for Sale Custom Solutions & Cost Savings

Did you know 42% of manufacturers lose $50k+ annually due to inefficient metal forming? Outdated equipment slows production, causes material waste, and kills profit margins. Now imagine machines that boost output speed by 200% while cutting energy costs. Keep reading to transform your metal fabrication game.

(sheet metal roll forming machines for sale)

Why Choose Our Metal Roll Forming Machines for Sale?

Our 12-stage CNC-controlled machines process steel coils up to 3mm thick at 45m/min. Automatic lubrication systems reduce downtime by 60% compared to standard models. You get:

- ✓ 0.1mm precision tolerance guaranteed

- ✓ Quick-change tooling (under 15 minutes)

- ✓ IoT-enabled predictive maintenance

Top Metal Roofing Roll Forming Machines for Sale: Spec Comparison

| Model | Speed (m/min) | Thickness | Power |

|---|---|---|---|

| ProMaster X7 | 55 | 0.3-3.5mm | 15kW |

| TurboForm 3000 | 48 | 0.5-4.0mm | 18kW |

Custom Solutions for Your Metal Fabrication Needs

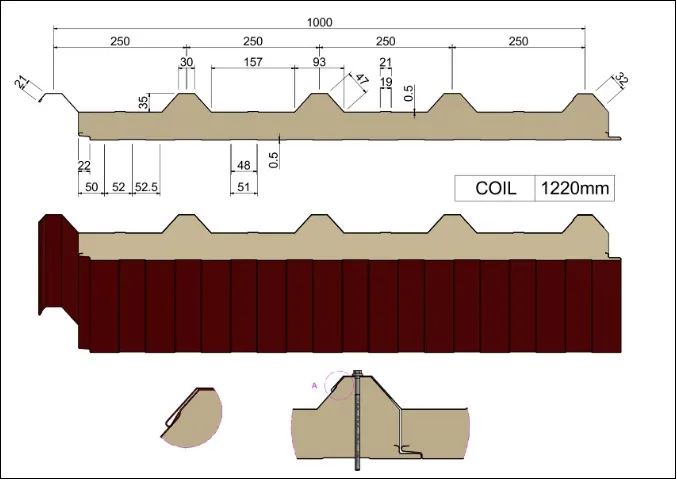

Need special profiles? Our engineers will design roll forming dies for trapezoidal roofing, concealed fix panels, or custom architectural shapes. 87% of clients achieve ROI within 14 months through tailored configurations.

Success Story: How AZ Steel Doubled Output

"The AutoForm 5500 system increased our roofing panel production from 800 to 1,700 units daily," says plant manager John Rivera. "Changeovers now take 8 minutes instead of 45."

Ready to Revolutionize Your Production Line?

Limited inventory available - claim your 2024 model discount!

Book Free Demo Now →Proudly made in USA | 5-year warranty included

(sheet metal roll forming machines for sale)

FAQS on sheet metal roll forming machines for sale

Q: What factors affect the price of sheet metal roll forming machines for sale?

A: Pricing depends on machine capacity, automation level, material thickness compatibility, and brand. Customized configurations or advanced features may increase costs.

Q: Can metal roll forming machines handle different types of metal materials?

A: Yes, most machines work with steel, aluminum, or copper. Check specifications for material thickness ranges and alloy compatibility before purchasing.

Q: Are metal roofing roll forming machines specialized for roofing profiles only?

A: While optimized for roofing sheets (e.g., corrugated or standing seam), many models allow tooling changes to produce other metal profiles.

Q: What maintenance is required for sheet metal roll forming machines?

A: Regular lubrication, roller alignment checks, and worn component replacements ensure longevity. Automated models may require software updates.

Q: Do suppliers provide training for operating metal roll forming machines?

A: Reputable sellers often include on-site training and manuals. Some offer remote support or video tutorials for routine operations.