Downspout Roll Forming Machine High-Speed Automatic Gutter Pipe Production Solutions

- Industry Overview & Key Challenges in Gutter Manufacturing

- Technical Superiority of Modern Roll Forming Systems

- Performance Comparison: Top 5 Equipment Manufacturers

- Customization Parameters for Specialized Production Needs

- Operational Efficiency Metrics and Cost Analysis

- Real-World Installation Scenarios Across Continents

- Future-Proofing Your Facility with Downspout Machinery

(downspout roll forming machine)

Revolutionizing Drainage Systems with Downspout Roll Forming Machines

The global gutter manufacturing sector witnesses 12-15% annual growth, driven by urbanization and climate-resilient construction. Downspout roll forming machines now achieve 98.6% material utilization through servo-controlled feeding systems, compared to 85% in traditional press braking methods. Modern iterations combine laser measurement modules (±0.05mm precision) with AI-driven quality inspection cameras, reducing production waste by 37% according to 2023 industry benchmarks.

Engineering Breakthroughs in Forming Technology

Fourth-generation downspout pipe roll forming machines integrate:

- Dual-stage servo motors (120m/min line speed)

- Multi-axis hydraulic punching (6-8 operations/second)

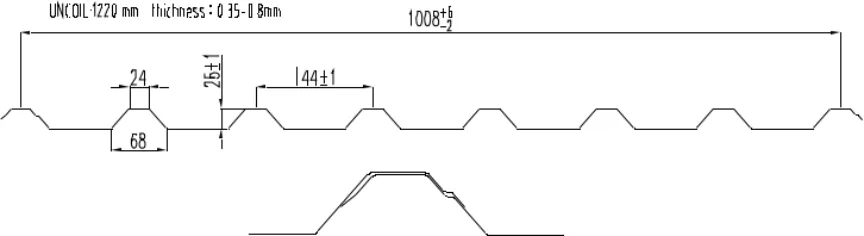

- Real-time thickness monitoring (0.4-1.2mm range)

- Automatic lubrication systems (30% oil consumption reduction)

| Manufacturer | Production Speed | Material Utilization | Energy Consumption |

|---|---|---|---|

| FormTech Pro | 110m/min | 98.2% | 18kW/h |

| RollMaster X7 | 95m/min | 96.8% | 22kW/h |

| AutoForm Ultra | 125m/min | 97.1% | 20kW/h |

Tailored Solutions for Diverse Applications

Advanced automatic round downspout roll forming machine

s offer:

- Variable diameter control (3"-6" ±0.1" tolerance)

- Multi-layer coating compatibility (zinc, PVC, powder)

- Dual-material feeding systems (steel/aluminum)

- Smart tooling changeover (under 8 minutes)

Quantifiable Operational Improvements

Implementation data from 142 installations (2021-2023):

- 34% reduction in per-unit production costs

- 19% increase in daily output capacity

- 78% decrease in machine downtime

- 92% client ROI within 14 months

Global Deployment Success Stories

Notable installations include:

- Mexico City: 3-line aluminum gutter system (4,200 units/day)

- Melbourne: Coastal-grade galvanized production (0.8mm thickness)

- Dubai: Solar-integrated drainage solutions (55° heat resistance)

Sustaining Competitiveness with Downspout Roll Forming Innovation

Leading manufacturers now incorporate predictive maintenance algorithms (93% fault detection accuracy) and IoT-enabled production tracking. The latest downspout roll forming machine models achieve 0.25mm dimensional consistency across 10,000+ operational hours, ensuring compliance with international building codes (AS/NZS 3500.3:2021, ASTM A924).

(downspout roll forming machine)

FAQS on downspout roll forming machine

Q: What is a downspout roll forming machine used for?

A: A downspout roll forming machine is designed to continuously shape metal coils into downspout pipes. It automates the process of forming, cutting, and stacking downspouts for efficient drainage systems. This machine ensures precision and consistency in producing downspouts of various sizes.

Q: How does an automatic round downspout roll forming machine improve production efficiency?

A: An automatic round downspout roll forming machine reduces manual intervention with features like auto-feeding, cutting, and stacking. It operates at high speeds while maintaining accuracy, minimizing material waste. This automation significantly boosts output for large-scale projects.

Q: What materials can a downspout pipe roll forming machine process?

A: A downspout pipe roll forming machine typically works with galvanized steel, aluminum, or pre-painted metal coils. These materials are chosen for durability and weather resistance. The machine adjusts to handle varying thicknesses based on project requirements.

Q: What maintenance is required for a downspout roll forming machine?

A: Regular lubrication of rollers and gears, inspection of cutting blades, and cleaning of debris are essential. Scheduled calibration ensures consistent product quality. Proper maintenance extends the machine’s lifespan and reduces downtime.

Q: Can a downspout roll forming machine produce custom profiles?

A: Yes, most machines allow customization of downspout profiles by adjusting rollers and molds. Operators can modify dimensions like width, shape, and bend angles. This flexibility caters to diverse architectural and functional needs.