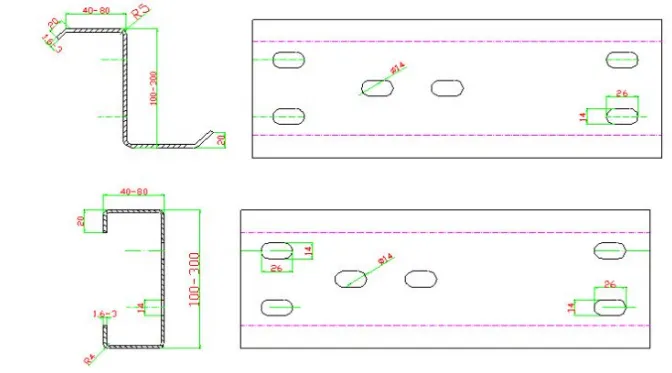

Drawings

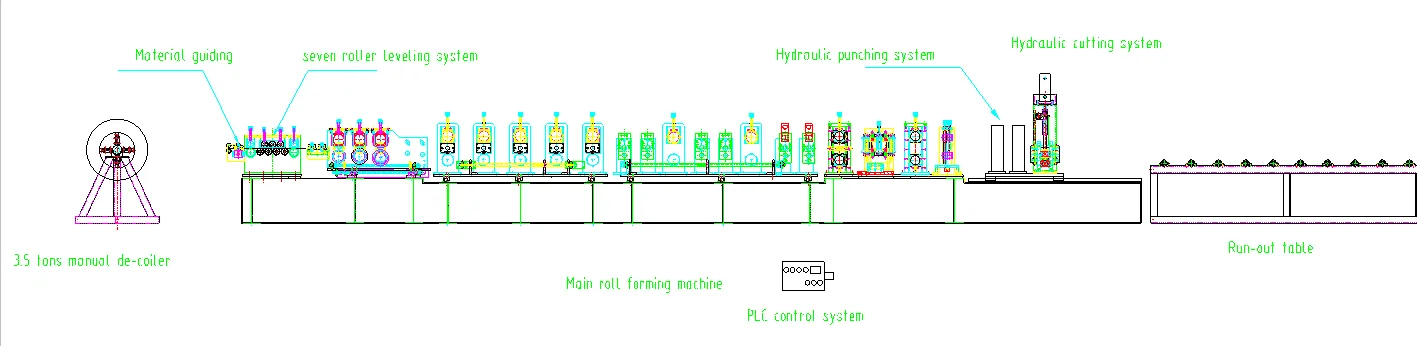

Flow chat

Component

|

Passive uncoiler |

1 set |

|

Feed guide |

1 set |

|

Leveling device |

1 set |

|

Main forming machine |

1 set |

|

Hydraulic punching |

1 set |

|

Hydraulic cutting system |

1 set |

|

Hydraulic station |

1 set |

|

PLC control system |

1 set |

|

Receiving table (3M * 2) |

1 set |

1.Passive uncoiler

1> Capacity: 5 tons

2> Bracing method: hand cranking, four link center outward bracing

3> Brake: double locking of main shaft

2.Feeding: guide shaft+guide wheel

3.Leveling device

Upper three lower four+two lead

Full solid spindle modulation heat treatment and polishing electroplating.

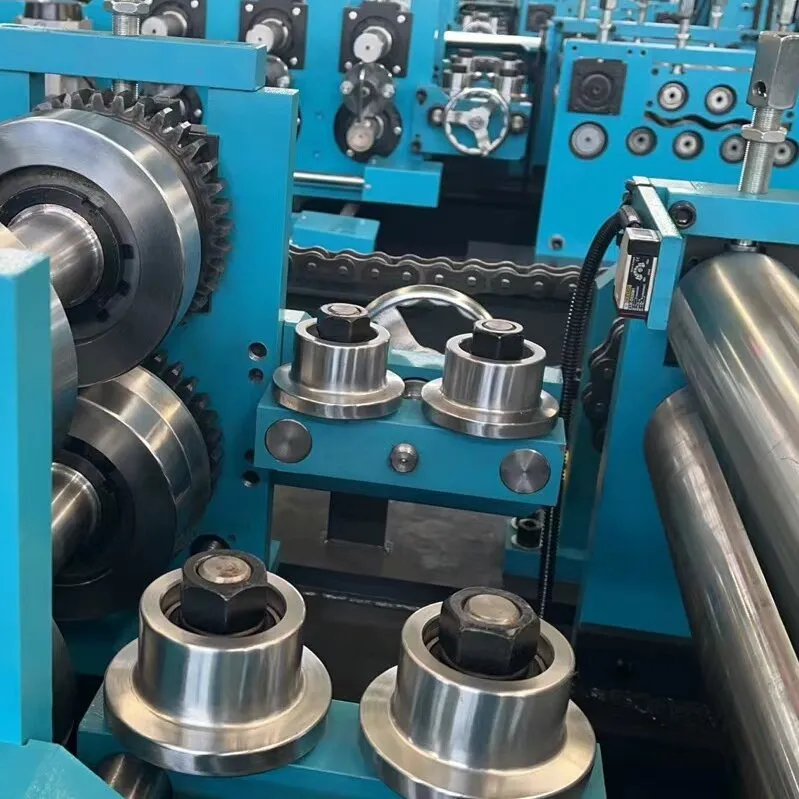

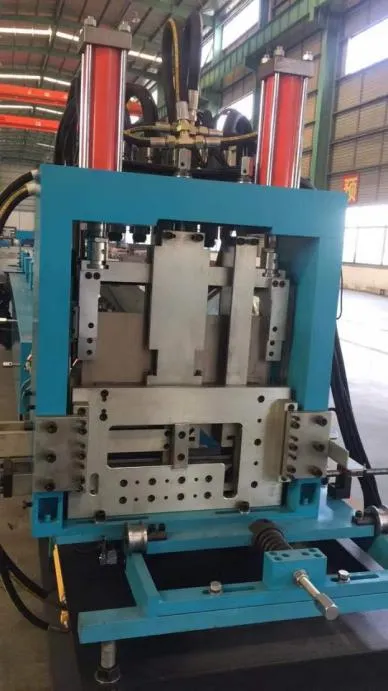

4.Main Forming machine

1> ① The width of C (80-300 mm) and Z (120-300 mm) can be changed during that; ② The waist height (40-80mm) can be changed freely;

③ Small edge (10-20mm);

④ Plate thickness t (1.5-3.0mm) adjustable

2> Discharge speed: high speed 2m/min (according to the number of holes punched)

3> Material application: Q195, Q235 hot-rolled strip steel or hot-rolled galvanized strip steel (1.5-3.0mm)

4> Main forming: 18 composition type (one of which is the waist height forming 87-95 degree random roll adjusting group) is equipped with 13 sets of CZ exchange modules, which can be switched by rotating 180 degrees, and the specifications can be changed by the electric button.

5>.Roll material: GCr15, process: heat treatment after CNC processing to HRC58-60, finish turning, polishing and electroplating

6>.shafts material:40Cr

Processing technology: after numerical control processing, HRC28-32 is modulated, and then finish turning, polishing and electroplating

7> Straightening: two axial straightening for ten roll CZ+four roll two axial straightening, two straightening units in total.

8> Feeding: equipped with transmission, driven by upper and lower shaft gears.

9>.Drive mode:6-1600 hydraulic five-star motor drive can achieve high and low speed, fast speed and high positioning accuracy.

10> Type change mode: (electric) type change, (three type change motors: 0.75 * 3kw)

Replacement distribution box: 1 (installed in the middle of the rack)

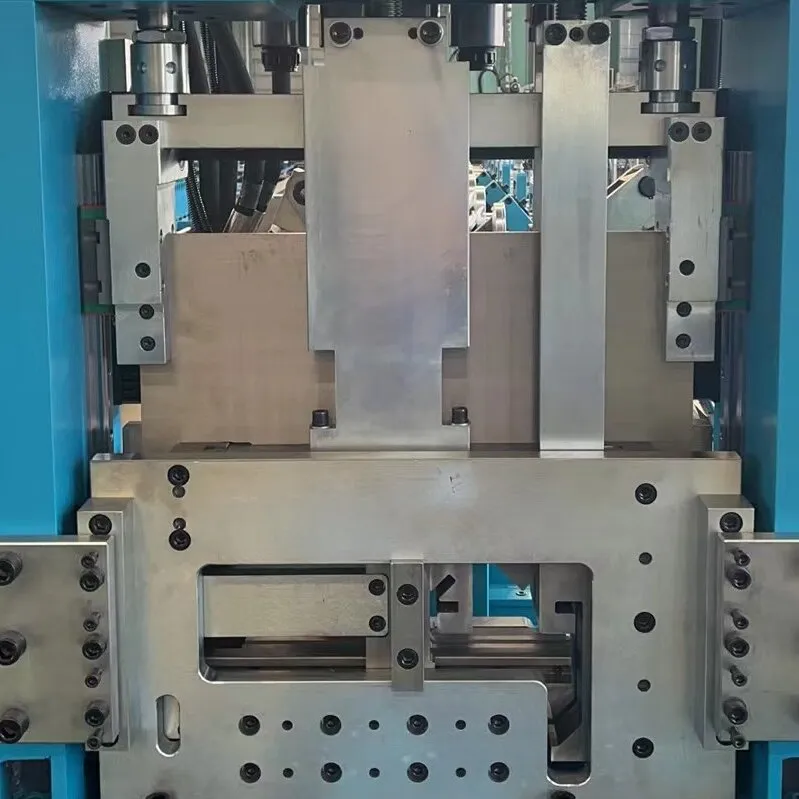

5.Hydraulic punching

Punching: single hole punching+double hole punching after forming, with round hole Φ 14mm and Φ 16mm and oval hole 26 × 16mm and 26 × 14mm。

(Customized according to requirements)

6.Hydraulic cutting

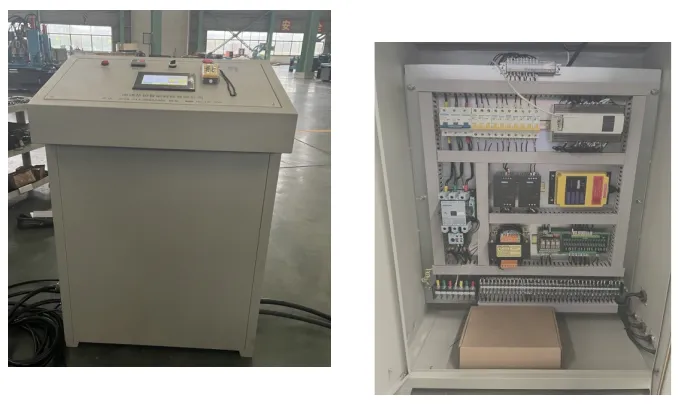

7.PLC Control system

|

1> External controller: 1 (convenient for production and commissioning Inching control forward and backward)

2> Origin of main accessories: PLC (Omron or Wuxi Xinjie), touch screen (Xinjie), relay (Omron), proximity switch (Otonix, South Korea), length encoder (Omron, Japan) |

|

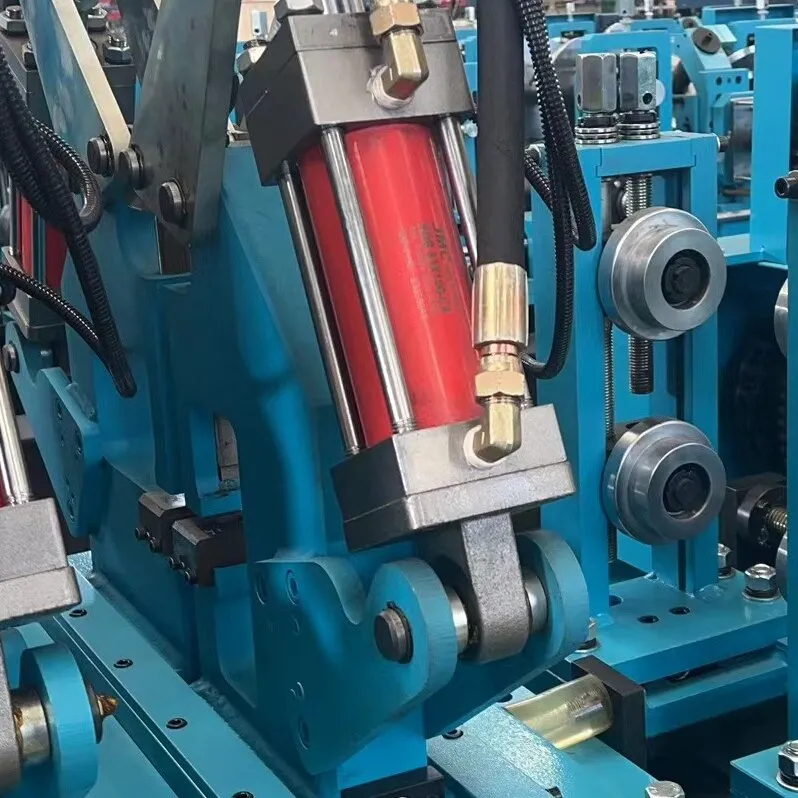

8.Hydraulic station

|

1> Hydraulic station: hydraulic station power 22KW Fuel tank capacity 350L 2>Origin of main parts: solenoid valve Beijing Huade |

9.Receiving table

|

1> Supporting material length: 3m 2 pieces

2> Material supporting method: the frame is welded with channel steel and angle steel, and the galvanized passive roller installed on the surface will not damage the galvanized layer of profile steel |

|

10.Products