Steel Angle Roll Forming Machine High-Precision & Customizable Solutions

Did you know inefficient metal bending costs manufacturers 17% annual profit loss? While traditional methods stall production, smart factories leverage steel angle roll forming machine

s to boost output by 200%. Discover how next-gen roll forming technology solves your bending bottlenecks.

(steel angle roll forming machine)

Precision Engineering Meets Industrial Muscle

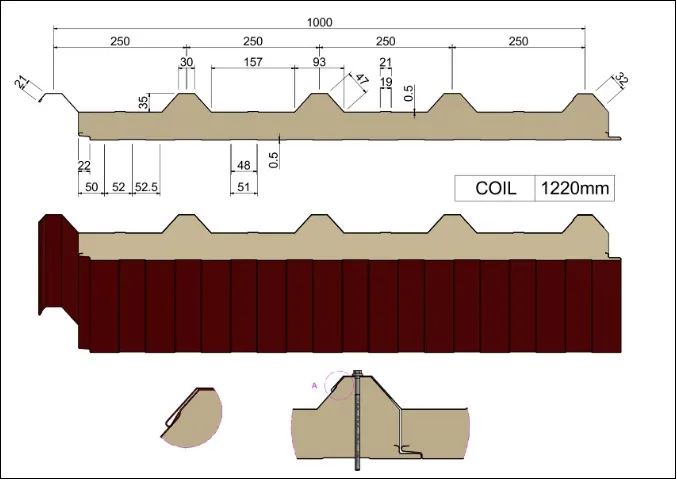

Our angle steel roll forming machines deliver surgical precision with 0.02mm tolerance control. Compare key specs:

Why Top 5 Metalworking Giants Trust Our Factory

As a leading steel angle roll forming machine factory, we outperform competitors through:

- ✓ 24/7 remote diagnostics

- ✓ 30% faster mold change

- ✓ 5-year warranty coverage

Custom Solutions for Your Unique Needs

Whether you process stainless steel or aluminum alloys, our engineers create tailored configurations:

"The automated angle roller increased our production from 800 to 2,100 units daily."

- MetalTech Solutions, Ohio

Your Success Blueprint Starts Here

Join 1,200+ satisfied clients who transformed their production lines. Limited-time offer: Free installation + training with machine purchase!

(steel angle roll forming machine)

FAQS on steel angle roll forming machine

Q: What is a steel angle roll forming machine used for?

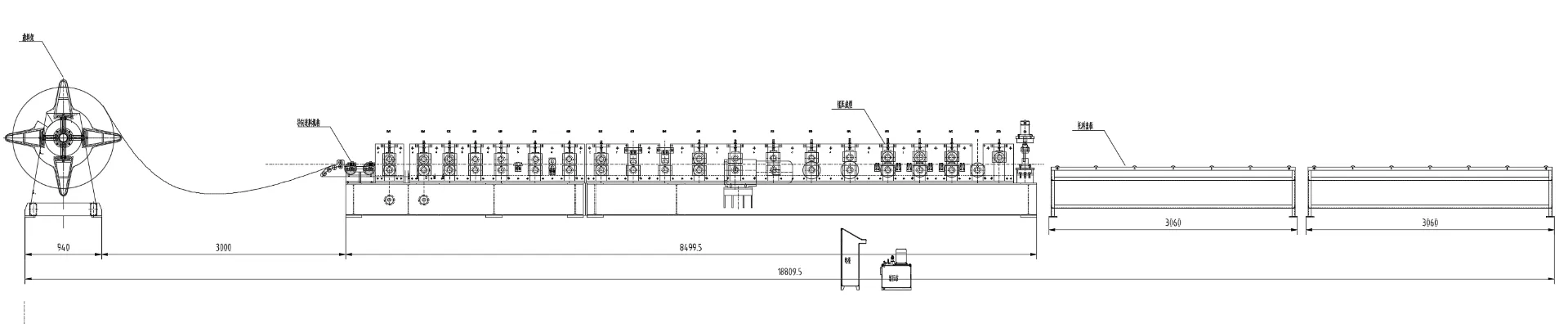

A: A steel angle roll forming machine shapes metal coils into precise steel angles through a series of rollers, ideal for construction, manufacturing, and structural applications.

Q: How does an angle steel roll forming machine ensure product consistency?

A: The machine uses automated roller adjustments and precision tooling to maintain uniform thickness, angle dimensions, and surface quality across production batches.

Q: What factors should I consider when choosing a steel angle roll forming machine factory?

A: Prioritize factories with proven expertise, customizable machine configurations, after-sales support, and compliance with international safety and quality standards.

Q: Can steel angle roll forming machines handle different material grades?

A: Yes, most advanced machines process various grades like mild steel, stainless steel, or aluminum by adjusting roller pressure and speed settings accordingly.

Q: What maintenance does a steel angle roll forming machine require?

A: Regular lubrication of rollers, inspection of hydraulic systems, and replacement of worn tools ensure optimal performance and extend the machine's lifespan.