Door Frame Roll Forming Machines Custom, High-Speed Solutions

- Understanding the Importance of Door Frame Forming Machines in Modern Construction

- Key Technical Advantages Driving Efficiency in Roll Forming Technology

- Comparative Analysis of Leading Suppliers and Manufacturers

- Customization Options for Diverse Industrial Needs

- Real-World Applications: Case Studies Across Industries

- Quality Assurance and Compliance Standards

- Future Trends in Door Frame Roll Forming Machinery

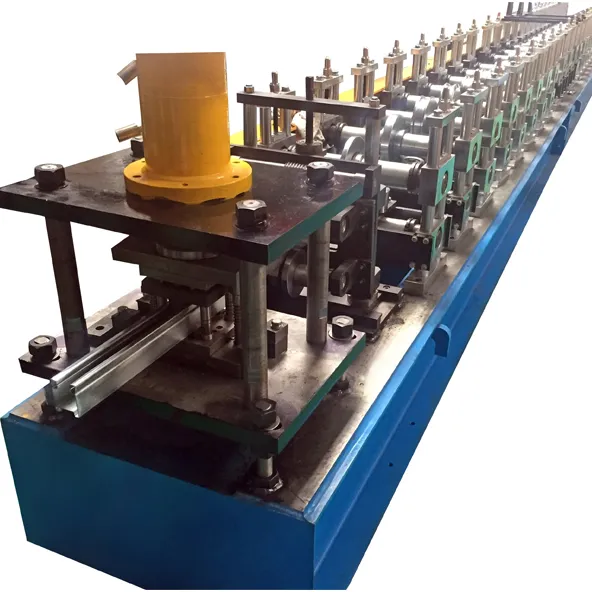

(door frame forming machine)

Why Door Frame Forming Machines Are Essential for Precision Engineering

The construction and metal fabrication industries rely heavily on precision-engineered components like door frames. A door frame forming machine

streamlines production by automating the shaping of metal coils into uniform profiles. These machines reduce material waste by up to 15% compared to manual methods, while increasing output speeds by 30-40%. With global demand for prefabricated building components rising at a CAGR of 6.8% (2023-2030), investing in advanced roll forming systems has become critical for manufacturers aiming to stay competitive.

Technical Innovations Enhancing Roll Forming Performance

Modern door frame roll forming machines integrate servo-driven controls, real-time thickness monitoring, and AI-powered error detection. For instance, leading models achieve tolerances within ±0.1mm, ensuring seamless assembly with other building elements. Energy-efficient designs now consume 25% less power than previous generations, and modular tooling allows rapid changeovers in under 10 minutes. Such advancements enable suppliers to cater to complex architectural specifications without compromising throughput.

Evaluating Top-Tier Manufacturers and Suppliers

| Supplier | Production Speed (m/min) | Customization Options | Energy Efficiency | Price Range (USD) |

|---|---|---|---|---|

| Supplier A | 12-18 | 15+ profile designs | ISO 50001 Certified | $85,000-$120,000 |

| Manufacturer B | 15-22 | Bespoke tooling | 22% reduction in kWh | $92,000-$135,000 |

| Supplier C | 10-16 | Multi-material compatibility | Solar-ready systems | $78,000-$110,000 |

Tailored Solutions for Unique Project Requirements

Leading door frame roll forming machine suppliers offer configurable systems to handle materials ranging from galvanized steel to aluminum alloys (0.4-2.0mm thickness). For example, a European contractor recently utilized a customized dual-axis machine to produce fire-rated frames meeting EN 1363-1 standards, achieving a 98% compliance rate during audits. Such flexibility ensures scalability for projects requiring niche certifications or non-standard dimensions.

Industry-Specific Success Stories

A commercial real estate developer in Southeast Asia reduced installation timelines by 40% after adopting automated roll forming systems from Manufacturer B. Similarly, a U.S.-based HVAC supplier improved component interchangeability by 75% using modular door frame machines. These cases highlight how optimized machinery directly impacts project ROI and operational agility.

Commitment to Durability and Regulatory Compliance

Reputable manufacturers subject their door frame roll forming machines to 500+ hours of stress testing, ensuring MTBF (Mean Time Between Failures) exceeds 8,000 hours. Compliance with CE, OSHA, and AS/NZS 4024 guarantees safe operation across international markets. Third-party validation from bodies like TÜV SÜD further reinforces quality claims, a factor 83% of B2B buyers prioritize during supplier selection.

Door Frame Roll Forming Machines: Shaping the Next Era of Construction

As smart factories embrace Industry 4.0, door frame forming machines are evolving with IoT-enabled predictive maintenance and blockchain-based material tracing. Early adopters report a 30% decrease in downtime through remote diagnostics. With 67% of metal fabricators planning to upgrade machinery by 2025, partnerships with innovative suppliers will determine market leadership in the coming decade.

(door frame forming machine)

FAQS on door frame forming machine

Q: What is a door frame roll forming machine used for?

A: A door frame roll forming machine automates the production of metal door frames by shaping coils into precise profiles. It ensures consistent quality and high efficiency for industrial manufacturing.

Q: How do I choose reliable door frame roll forming machine suppliers?

A: Evaluate suppliers based on industry experience, customer reviews, and after-sales support. Reputable suppliers often provide technical specifications, customization options, and warranty coverage.

Q: What certifications should door frame roll forming machine manufacturers have?

A: Look for manufacturers with ISO certification, CE compliance, and safety standards. These certifications ensure adherence to international quality and safety protocols.

Q: Can door frame roll forming machines be customized for specific designs?

A: Yes, many suppliers offer customizable machines for unique profiles, thicknesses, and materials. Discuss your requirements to ensure compatibility with production needs.

Q: What maintenance is required for a door frame roll forming machine?

A: Regular lubrication, alignment checks, and part inspections are essential. Manufacturers typically provide maintenance guidelines to maximize machine lifespan and performance.