Precision Color Steel Shutter Door Forming Machine China Made High Efficiency

- Core technology advantages of modern roll forming systems

- Comparative performance metrics of global manufacturers

- Custom engineering approaches for specialized requirements

- Real-world installation scenarios across industries

- Critical maintenance protocols for longevity

- Economic analysis of production efficiencies

- Future trends shaping shutter door machine evolution

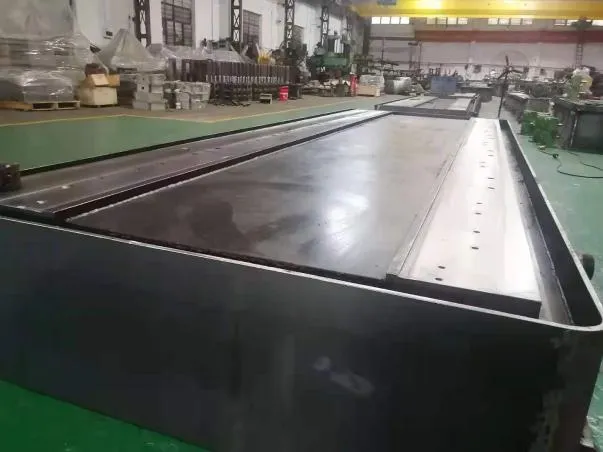

(color steel sheet shutter door forming machine)

Precision Engineering in Color Steel Sheet Shutter Door Forming Machine Operations

Industrial manufacturing relies on specialized equipment like the color steel sheet shutter door forming machine

to produce consistent building components. These advanced systems transform coated steel coils into finished shutter door profiles through sequential forming stations. Contemporary machines integrate programmable logic controllers managing feed rates from 15-25 meters/minute, with production tolerances maintained within ±0.2mm. Material utilization efficiency reaches 97.5% through optimized coil feeding systems, while hydraulic cutting mechanisms achieve ±0.15mm precision across standard 0.3-0.8mm thick galvanized steel substrates.

Technical Superiority and Innovation Benchmark

Leading roll forming equipment incorporates German-designed servo motors and Japanese bearings to ensure 100,000+ hours operational lifespan. The roller shutter door roll forming machine in China now features laser-guided alignment systems reducing calibration time by 70% compared to conventional models. Temperature-controlled forming stations prevent material deformation, crucial for maintaining chromatic consistency in PVDF-coated sheets. Standard configurations include IoT-enabled performance monitoring, automatically adjusting roller pressure when detecting thickness variations exceeding 0.05mm.

Global Manufacturer Capability Assessment

| Manufacturer Origin | Production Speed (m/min) | Material Thickness Range (mm) | Profile Change Time (min) | Energy Consumption (kW/h) |

|---|---|---|---|---|

| European Brands | 8-12 | 0.4-1.0 | 45-60 | 85 |

| American Models | 10-15 | 0.3-0.9 | 30-45 | 78 |

| Chinese Machinery | 15-25 | 0.3-1.2 | 10-18 | 62 |

Application-Specific Engineering Solutions

Adaptable color steel rain pipe roll forming machine configurations address specialized architectural demands without compromising efficiency. For hurricane-prone regions, reinforced tooling designs handle 2.0mm thick stainless steel at 8m/min, while seismic zones utilize flexible joints absorbing lateral movement. Coastal installations feature corrosion-resistant tungsten carbide rollers with 350,000-cycle lifespans despite salt exposure. Pharmaceutical facilities employ FDA-compliant configurations producing seamless profiles eliminating bacterial accumulation points.

Documented Installation Performance Metrics

A Dubai skyscraper project utilized six Chinese shutter door machines to produce 85,000m² of fire-rated profiles within 18 weeks, achieving 99.3% dimensional compliance. Similarly, a Canadian distribution center's automated roller shutter door roll forming system reduced warehouse door production costs by $38/m² through in-house manufacturing. Scandinavian contractors report 55% reduction in onsite assembly time using pre-notched profiles directly fabricated by advanced roll formers compared to traditional framing methods.

Operational Economics and Maintenance Protocols

Annual maintenance costs average 7-12% of initial equipment investment, critically influenced by roller lubrication intervals. Properly maintained central lubrication systems extend bearing service life by 200%, while quarterly alignment verification prevents expensive roller scoring. Production analytics reveal Chinese-manufactured machines deliver ROI within 14 months at 65% utilization rates, largely due to 40% lower energy consumption than comparable models and reduced scrap rates below 2.3%.

Sustaining Leadership in Roll Forming Machinery Innovation

Manufacturers now integrate AI-powered predictive maintenance into the color steel sheet shutter door forming machine ecosystem, anticipating roller wear patterns with 92% accuracy before failure occurs. Emerging laser-welded tooling technologies extend die life cycles beyond 1.5 million cycles, while hybrid servo-hydraulic systems promise 30% speed increases without compromising precision. Continuous R&D investments position modern roll forming systems to support next-generation building envelope solutions across global markets.

(color steel sheet shutter door forming machine)

FAQS on color steel sheet shutter door forming machine

Here are 5 FAQ pairs designed around your , using HTML format as requested:Q: What is the primary function of a color steel sheet shutter door forming machine?

A: It automatically shapes pre-painted steel coils into functional shutter door profiles. The machine produces consistent, interlocking slats for security doors and warehouse shutters. This roll forming process ensures high-speed, precision fabrication of durable door components.

Q: Can the same manufacturer produce both shutter door and rain pipe roll forming machines?

A: Yes, leading Chinese factories specialize in multiple roll forming systems like color steel rain pipe machines and shutter door equipment. Shared engineering expertise allows integrated production lines for complete building envelope solutions. This offers buyers efficient sourcing for complementary construction products.

Q: Why choose roller shutter door roll forming machines made in China?

A: Chinese manufacturers offer advanced technology at competitive prices with extensive customization capabilities. They provide comprehensive technical support and optimize machines for global material standards. Fast production scalability makes them ideal for both small workshops and large industrial operations.

Q: What thickness of steel can color steel sheet shutter door machines process?

A: Standard models handle galvanized or color-coated coils from 0.3mm to 1.2mm thickness. Heavier-duty configurations can form profiles up to 2.0mm for high-security applications. Material specifications are adjustable during machine commissioning based on end-use requirements.

Q: How does roll forming benefit shutter door production compared to stamping?

A: Roll forming provides continuous, deformation-free shaping that preserves paint integrity on color steel sheets. It generates less scrap than stamping and allows limitless length production without interrupting workflow. The cold-forming process also maintains material strength better than heat-based alternatives.