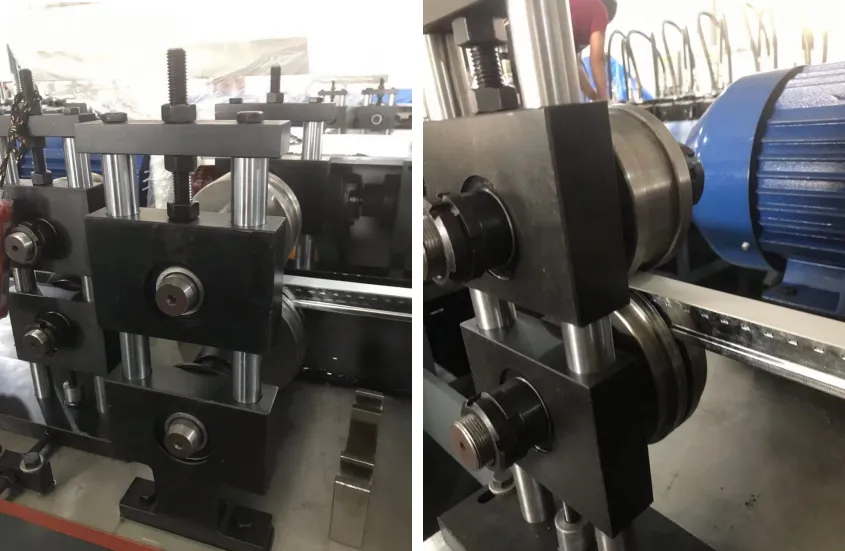

Our Automatic T Grid Ceiling Roll Forming Machine is engineered with advanced technology that allows for seamless operation and exceptional performance. With a production capacity of up to 30 meters per minute, this machine significantly enhances productivity, making it ideal for both small-scale workshops and large manufacturing facilities. The user-friendly interface and automated controls enable operators to easily set parameters, monitor production, and make adjustments on the fly, ensuring consistent quality in every batch.

Constructed from high-grade materials, the machine boasts durability and longevity, reducing maintenance costs and downtime. Its precision roll forming process guarantees uniformity in dimensions, resulting in perfectly shaped T grids that fit seamlessly into any ceiling installation. The machine is compatible with a variety of materials, including galvanized steel and aluminum, allowing for versatility in production.

Safety is a top priority, and our Automatic T Grid Ceiling Roll Forming Machine is equipped with multiple safety features, including emergency stop buttons and protective guards, ensuring a secure working environment. Additionally, the compact design of the machine allows for easy integration into existing production lines, maximizing space efficiency.

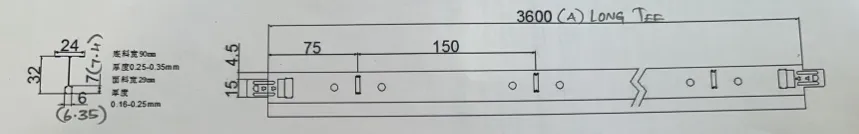

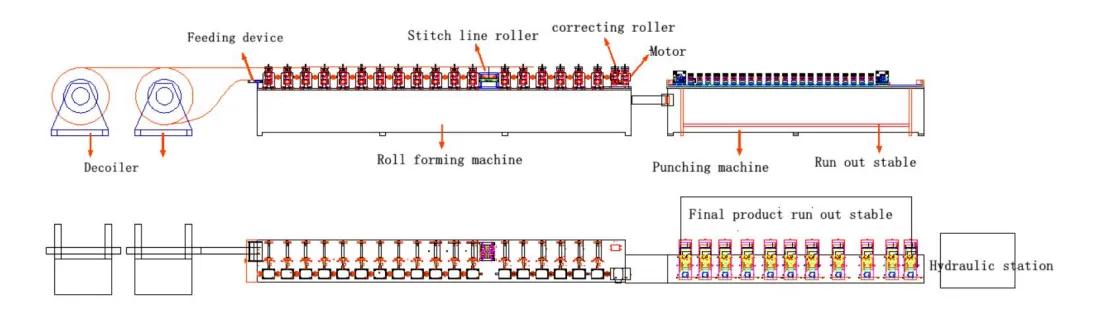

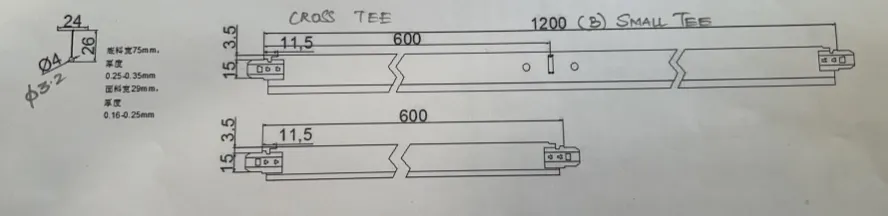

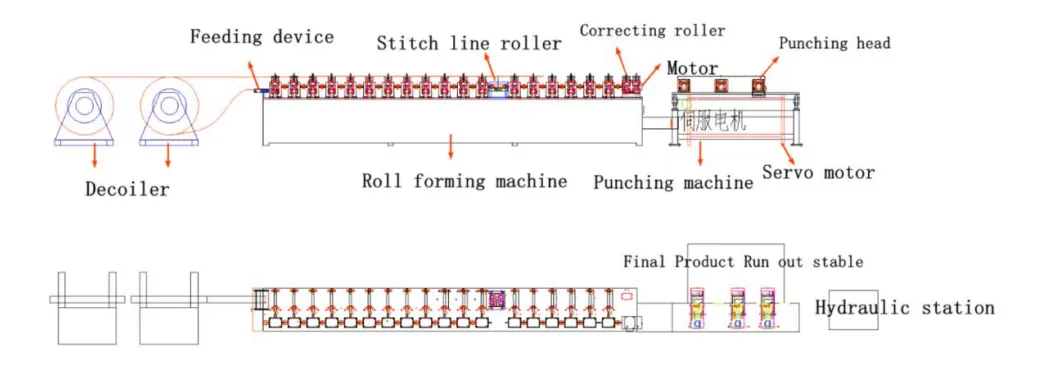

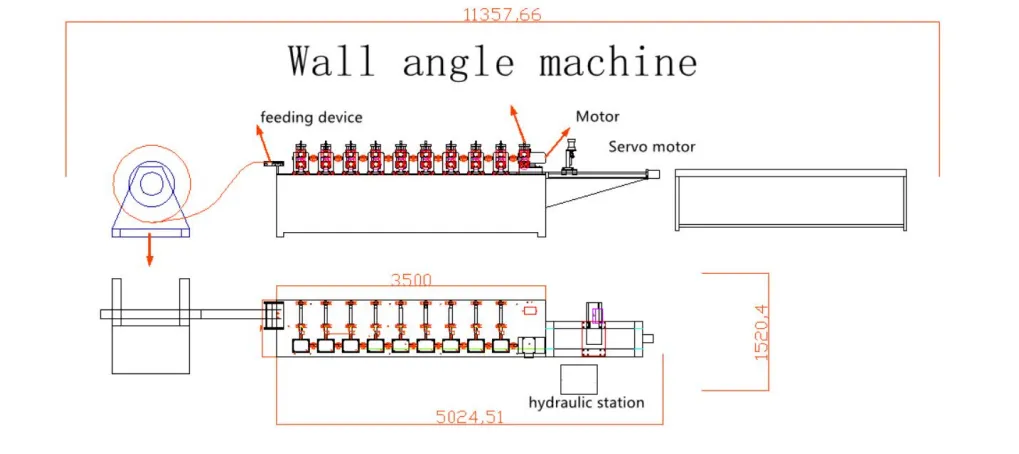

Drawings and working process

Main T:

Cross T

Angle

Technical Parameters