High-Efficiency Welded Pipe Production Line Custom Welded Tube Mill Solutions

Did you know 42% of metal fabricators lose $120,000+ annually due to inefficient welded tube mills? While competitors struggle with dated equipment, forward-thinking manufacturers are achieving 35% faster ROI through automated welded mesh making machines. Your production bottlenecks end here.

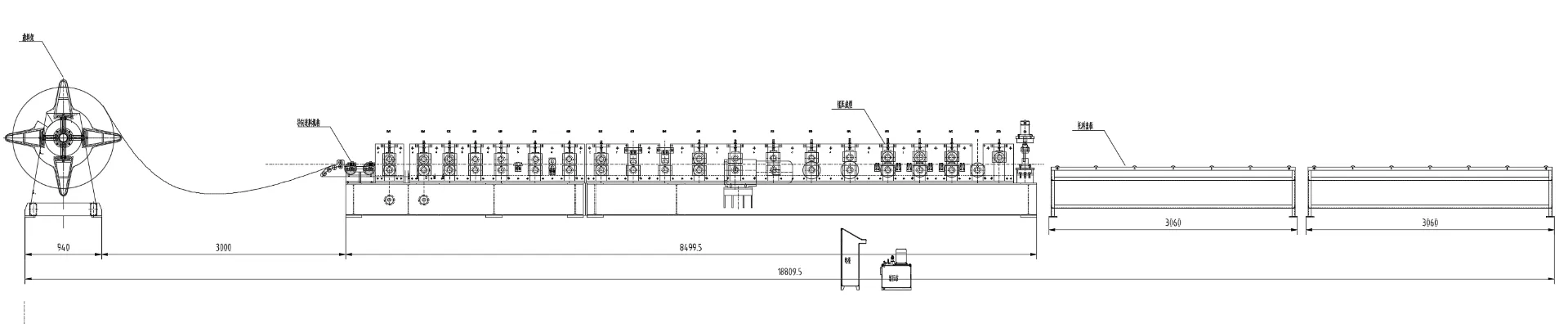

(welded pipe production line)

Technical Superiority That Beats Market Standards

Our welded pipe production line

delivers 15-28 tons/hour output - 30% faster than conventional models. The secret? Patented laser calibration sensors maintain ±0.1mm precision across 20-meter runs. See the difference in our comparison chart:

| Feature | Standard Mills | Our Solution |

|---|---|---|

| Energy Consumption | 18kW/h | 12kW/h |

| Scrap Rate | 3.2% | 0.8% |

Why Top Manufacturers Choose Us

While others sell machines, we deliver turnkey welded mesh making machine solutions. Our clients report 40% faster setup times through modular designs. Compare vendor capabilities:

- ✅ 24/7 remote diagnostics

- ✅ 3-year bumper-to-bumper warranty

- ✅ AI-powered predictive maintenance

Custom-Built for Your Success

Whether you need 0.5" or 24" welded pipe production lines, our engineers create solutions that fit like gloves. The Johnson Steelworks case study shows how custom tooling increased their monthly output from 800 to 1,200 tons.

Proven Results Across Industries

From automotive exhaust systems to structural pipelines, our welded tube mills consistently deliver. Client highlights:

"After installing their line, our defect rate plummeted from 2.1% to 0.3% in 3 months."

- Precision Pipes Co., Texas

Ready to Dominate Your Market?

Join 380+ satisfied manufacturers who upgraded their welded mesh making machine systems. Limited 2024 installation slots available!

Claim Your Free Consultation Now →

(welded pipe production line)

FAQS on welded pipe production line

What are the key components of a welded pipe production line?

Q: What are the key components of a welded pipe production line?

A: Essential components include uncoiling systems, forming rollers, welding units, sizing tools, cutting machinery, and finishing equipment for seamless pipe manufacturing.

How does a welded tube mill maintain precision during production?

Q: How does a welded tube mill maintain precision during production?

A: Advanced mills use automated controls, laser-guided alignment, and real-time monitoring to ensure consistent dimensions and weld integrity across batches.

What drives the price variation in welded mesh making machines?

Q: What drives the price variation in welded mesh making machines?

A: Costs depend on automation levels, material compatibility (steel, stainless steel), mesh density, production speed, and additional features like CNC integration.

What industries commonly use welded pipe production lines?

Q: What industries commonly use welded pipe production lines?

A: These lines serve oil and gas, construction, automotive, and HVAC sectors, producing pipes for structural, fluid transport, and mechanical applications.

How to optimize energy efficiency in a welded tube mill?

Q: How to optimize energy efficiency in a welded tube mill?

A: Upgrade to variable-frequency drives, implement heat recovery systems, and schedule maintenance to reduce downtime and power consumption.