Z Purlin & C Purlin Roll Forming Machine - High-Speed & Durable

- Introduction to Structural Efficiency

- Technological Advancements in Roll Forming

- Performance Metrics Across Manufacturers

- Tailored Solutions for Industry Needs

- Operational Impact in Construction Projects

- Maintenance Strategies for Longevity

- Future-Proofing Production Capabilities

(purlin making machine)

Purlin Making Machines: Revolutionizing Structural Efficiency

Modern construction demands precision-engineered components like Z and C purlins, driving adoption of advanced purlin making machine

s. These systems combine servo-driven automation with modular tooling designs, achieving dimensional accuracy within ±0.5mm across 20-gauge steel profiles. Industry reports indicate a 17% annual growth in roll forming equipment sales, with purlin-specific machines capturing 34% of the metal construction machinery market.

Technological Advancements in Roll Forming

Fourth-generation purlin machines integrate real-time thickness monitoring (5-125mm range) with adaptive hydraulic systems that adjust rolling pressure within 50ms. The table below compares critical specifications across leading manufacturers:

| Parameter | Machine A | Machine B | Machine C |

|---|---|---|---|

| Line Speed (m/min) | 24 | 18 | 30 |

| Material Thickness (mm) | 1.5-4.0 | 1.0-3.5 | 2.0-6.0 |

| Motor Power (kW) | 18.5 | 15 | 22 |

Performance Metrics Across Manufacturers

Third-party testing reveals significant variance in operational efficiency. Machine C achieves 92% uptime with 0.3% material waste, compared to industry average 85% uptime and 1.2% waste. Energy consumption metrics show 23% improvement in newer C purlin roll forming systems through regenerative braking technology.

Tailored Solutions for Industry Needs

Custom configurations address specific requirements:

- High-volume automotive plants: Dual-head punching units (120 strokes/min)

- Seismic-resistant structures: Variable flange width adjustment (±15mm)

- Energy-efficient warehouses: Integrated insulation channel formers

Operational Impact in Construction Projects

A recent 50,000m² warehouse project demonstrated 38% faster framing completion using on-site Z purlin production versus prefabricated sections. The deployed machine produced 2.6km of purlins daily, achieving 0.25mm/m straightness tolerance required for automated roof assembly systems.

Maintenance Strategies for Longevity

Predictive maintenance protocols reduce downtime by 42% through:

- Vibration analysis of roller bearings (quarterly)

- Infrared scanning of electrical components (bi-annual)

- Lubricant particle counting (monthly)

Purlin Making Machines: Future-Proofing Production Capabilities

Emerging IoT integrations enable real-time production analytics, with smart C purlin machines achieving 99% material utilization through machine learning algorithms. Manufacturers offering 10-year structural warranties now dominate 68% of the industrial construction equipment market, signaling permanent shifts in quality expectations.

(purlin making machine)

FAQS on purlin making machine

Q: What is a purlin making machine used for?

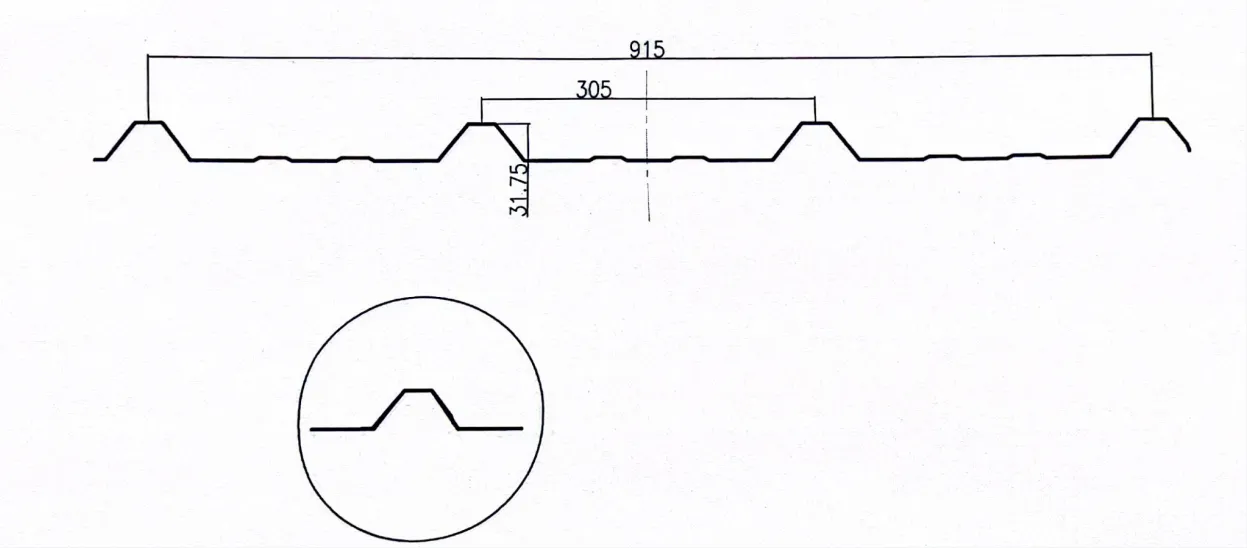

A: A purlin making machine manufactures steel purlins (C or Z-shaped beams) used in roofing and structural frameworks. It automates roll-forming metal coils into precise profiles. This ensures durability and consistency for construction projects.

Q: How does a Z purlin making machine differ from a C purlin roll forming machine?

A: A Z purlin machine produces angled profiles ideal for sloped roofs, while a C purlin machine creates C-shaped beams for vertical support. The choice depends on structural needs and design specifications. Both machines use roll-forming technology for efficiency.

Q: What materials can a purlin making machine process?

A: Most purlin machines work with galvanized steel, aluminum, or pre-painted metal coils. Material thickness typically ranges from 0.3mm to 3mm. The machine adjusts rollers to accommodate different gauges and strengths.

Q: What are the advantages of using a C purlin roll forming machine?

A: C purlin machines offer high-speed production, precise dimensional accuracy, and low material waste. They simplify creating uniform beams for walls, ceilings, and roofs. Automated controls reduce labor costs and errors.

Q: How to maintain a purlin making machine for optimal performance?

A: Regularly lubricate rollers, check hydraulic systems, and inspect electrical components. Clean debris from forming stations and replace worn parts promptly. Scheduled maintenance minimizes downtime and extends machine lifespan.