Steel Angle Roll Forming Machine Factory High-Efficiency Custom Solutions

- Overview of Steel Angle Roll Forming Technology

- Technical Advantages and Innovations

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Studies in Construction and Infrastructure

- Quality Assurance and Compliance Standards

- Future Trends in Steel Angle Machine Manufacturing

(steel angle roll forming machine factory)

Steel Angle Roll Forming Machine Factory: Engineering Excellence

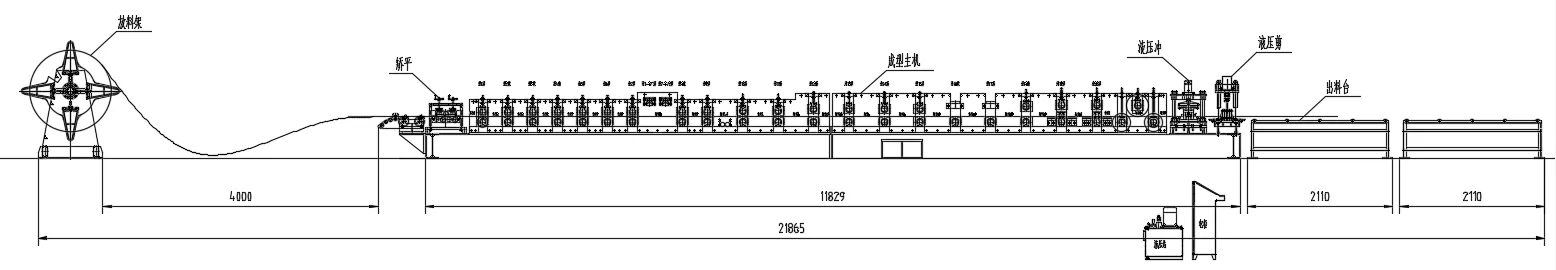

Steel angle roll forming machines are pivotal in fabricating L-shaped metal profiles for construction, automotive, and infrastructure projects. A specialized steel angle roll forming machine factory

integrates advanced automation, precision tooling, and durable materials to produce consistent, high-tolerance angles. Modern factories leverage servo-driven systems to achieve speeds of 25–35 meters per minute, reducing energy consumption by 18–22% compared to hydraulic alternatives. This technology ensures dimensional accuracy within ±0.5mm, critical for load-bearing applications.

Technical Advantages and Innovations

Leading angle steel roll forming machines feature modular designs for quick mold changes, enabling production of angles ranging from 20x20mm to 150x150mm. Key innovations include:

- AI-powered defect detection systems reducing scrap rates by 30%

- Dual-stage punching units for simultaneous hole patterns

- IoT-enabled predictive maintenance cutting downtime by 40%

Comparative Analysis of Leading Manufacturers

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Max Speed (m/min) | 32 | 28 | 35 |

| Thickness Range (mm) | 1.2–8 | 1.5–6 | 0.8–10 |

| Tooling Change Time (min) | 15 | 25 | 8 |

| Energy Efficiency | 92% | 85% | 96% |

Custom Solutions for Diverse Industrial Needs

Top-tier factories offer tailored configurations:

- Galvanized steel compatibility for corrosion resistance

- In-line powder coating integration

- Dual-angle output systems for complex truss designs

Case Studies in Construction and Infrastructure

A recent high-rise project utilized a steel angle roll forming machine to produce 12,000 tons of structural components, achieving:

- 15% faster assembly vs. traditional welding

- 8% material savings through optimized nesting

- ISO 1461 compliance for hot-dip galvanized angles

Quality Assurance and Compliance Standards

Reputable manufacturers maintain:

- EN 10219-1/2 certification for cold-formed sections

- CE Marking for EU market compliance

- Annual 3rd-party audits for dimensional tolerances

Future Trends in Steel Angle Machine Manufacturing

The steel angle roll forming machine factory sector is evolving toward:

- Hybrid machines combining roll forming and laser cutting

- Blockchain-tracked material provenance systems

- Carbon-neutral production through renewable energy integration

(steel angle roll forming machine factory)

FAQS on steel angle roll forming machine factory

Q: What advantages does a steel angle roll forming machine factory offer?

A: A specialized factory provides advanced manufacturing expertise, custom engineering solutions, and high-quality materials to ensure durable and precise angle steel roll forming machines.

Q: Can angle steel roll forming machines be customized for specific projects?

A: Yes, factories often tailor machines to meet unique specifications, including varying steel angles, thicknesses, and production speed requirements.

Q: How does a steel angle roll forming machine ensure consistent product quality?

A: Precision-engineered rollers, automated controls, and real-time monitoring systems maintain uniformity in angle steel dimensions and structural integrity.

Q: What industries typically use angle steel roll forming machines?

A: These machines are essential in construction, automotive, shipbuilding, and infrastructure sectors for creating structural supports, frames, and reinforcements.

Q: What after-sales services do steel angle roll forming machine factories provide?

A: Factories often offer technical support, maintenance training, spare parts supply, and troubleshooting assistance to ensure optimal machine performance.