Product Description

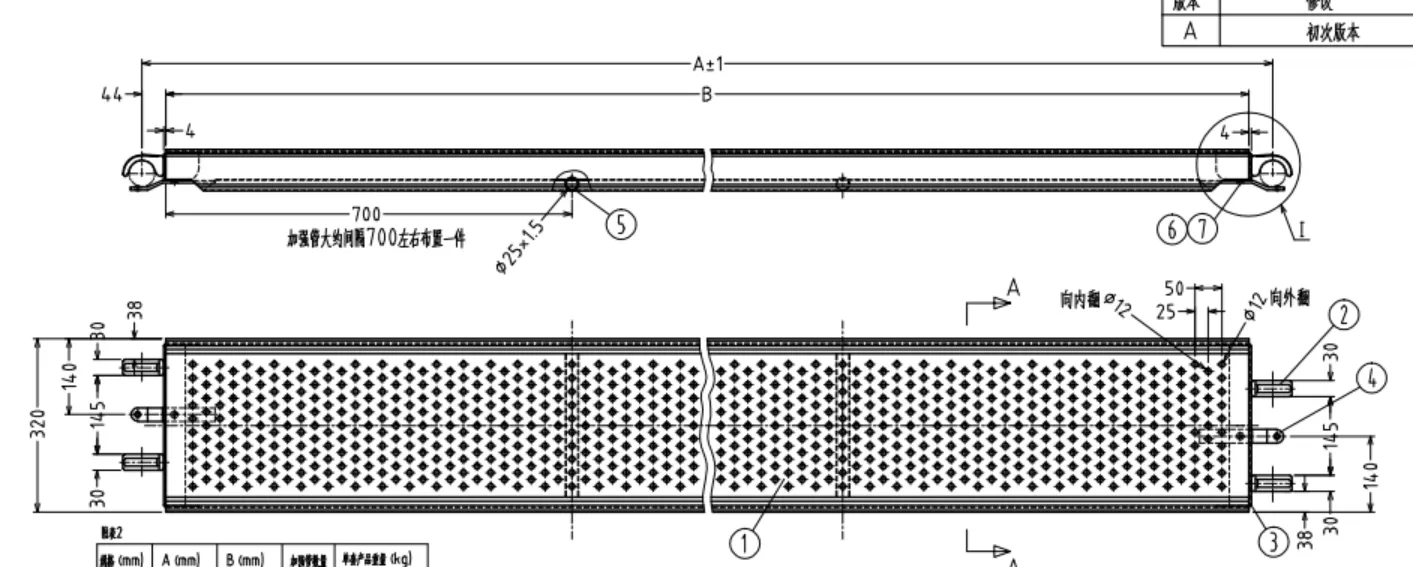

Drawings

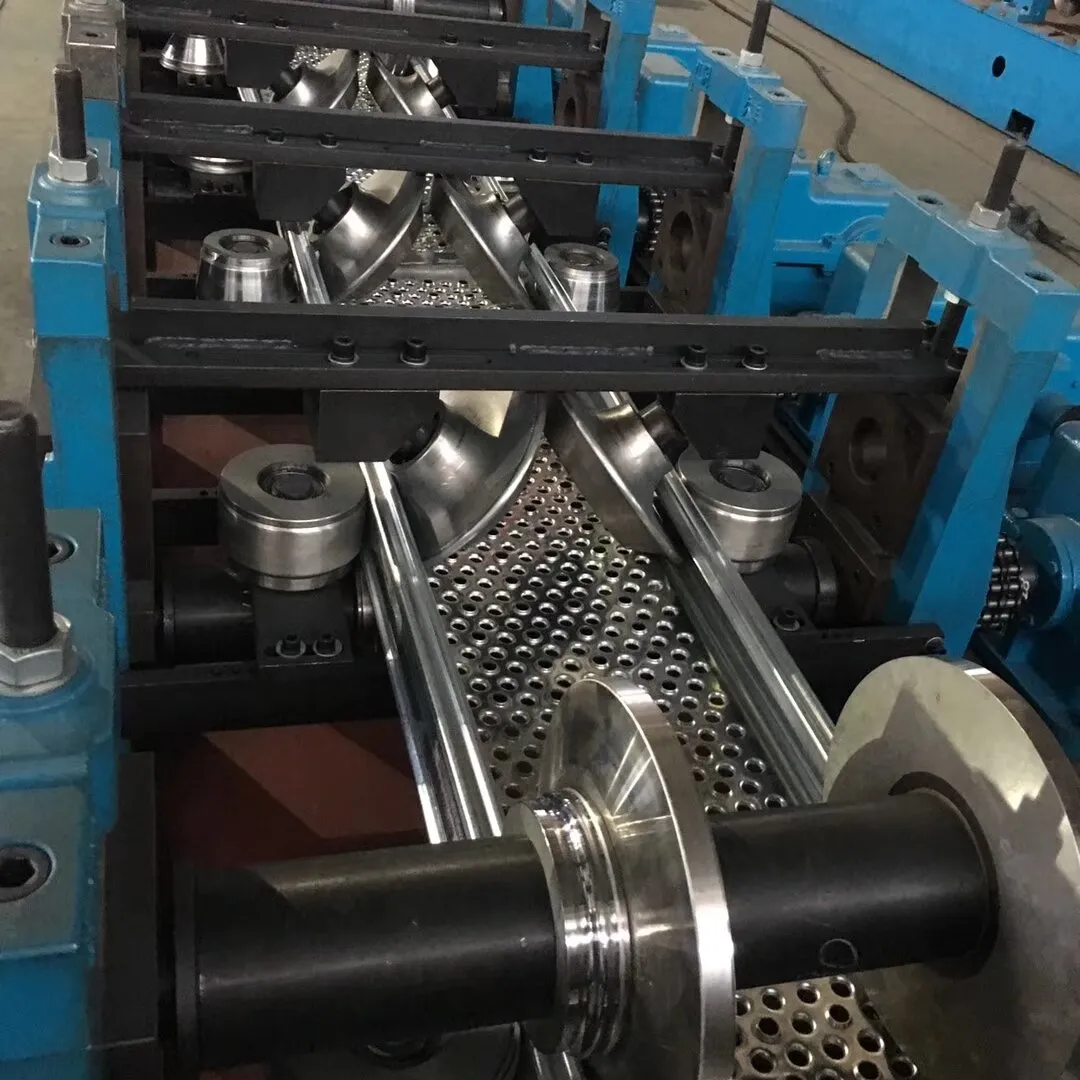

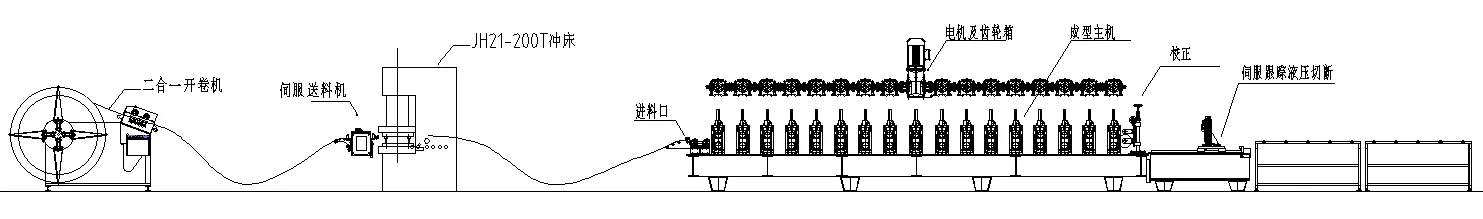

Processus et components

| 5 ton de-coiler with leveling | x1 set |

| Servo feeding machine | x1 set |

| 125T Punching machine with moulds | x1 set |

| Pelagus volumine formatam machinam | x1 set |

| Servo track cutting | x1 set |

| HYDRAULICUS station | x1 set |

| PLC Control system | x1 set |

| Currere de mensa (3M * II) | x1 set |

Processus working

Technical parametri