EPS Sandwich Panel Production Line: High-Efficiency & Quality

The Evolution and Impact of EPS Sandwich Panel Production Lines in Modern Construction

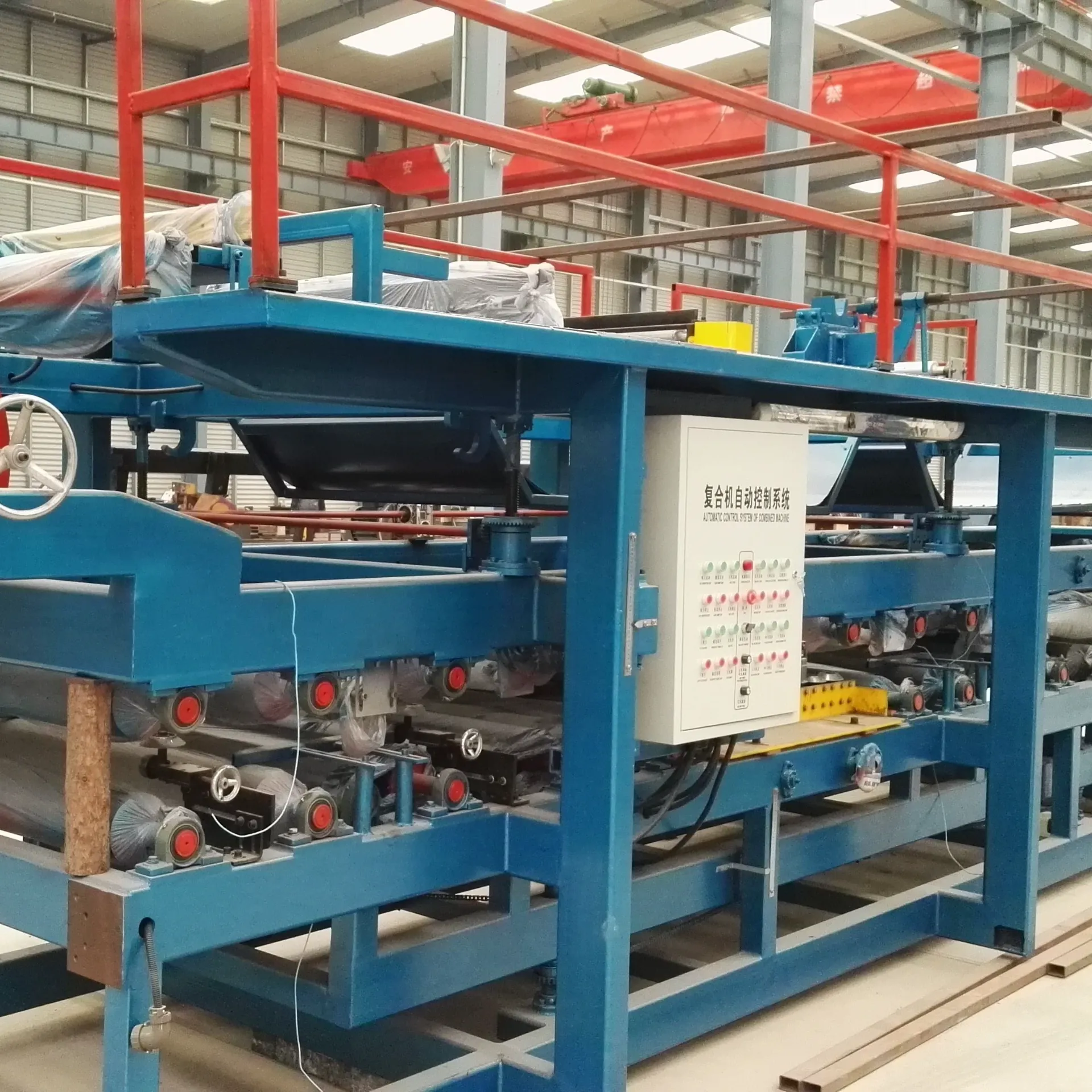

The global construction industry is continuously seeking innovative materials and efficient manufacturing processes to meet escalating demands for sustainable, cost-effective, and high-performance building solutions. In this context, the Eps Sandwich Panel Production Line stands as a cornerstone technology. These advanced systems are pivotal in fabricating insulated panels that integrate structural integrity with superior thermal performance. As urbanization accelerates and energy efficiency standards tighten, the demand for insulated panels, particularly those with Expanded Polystyrene (EPS) cores, has surged. This has, in turn, fueled significant advancements in the machinery and automation that produce them, transforming how modern structures are designed and erected. Understanding the intricate details of an eps panel production line is crucial for stakeholders aiming to invest in state-of-the-art manufacturing capabilities.

Beyond their immediate application in building construction, EPS sandwich panels contribute significantly to energy conservation, aligning with global efforts to reduce carbon footprints. The manufacturing processes involved have evolved from rudimentary batch production to highly automated, continuous lines, ensuring consistent quality and high output volumes. This evolution reflects a broader industry trend towards lean manufacturing and precise engineering, where every component of the production line, from raw material feeding to final panel stacking, is optimized for efficiency and minimal waste. The strategic integration of cutting-edge technology into an eps sandwich panel machine underscores its importance in meeting the diverse needs of contemporary architecture and industrial applications.

Deciphering the Advanced Manufacturing Process of EPS Sandwich Panels

The manufacturing of EPS sandwich panels through a dedicated production line is a sophisticated, multi-stage process designed for precision and efficiency. It typically involves continuous lamination, where different material layers are precisely bonded together under controlled conditions. This contrasts with older methods like casting or forging, which are unsuitable for composite panel fabrication. The primary materials typically include galvanized or pre-painted steel sheets for the facings and an EPS foam core, which provides exceptional insulation. Adhesives, usually two-component polyurethanes, play a critical role in establishing a robust bond between the core and the facings.

Key Stages of the Production Process:

- Coil Feeding and Profiling: Steel coils are unwound and fed into profiling machines to form desired rib or corrugated patterns, enhancing rigidity and aesthetic appeal. This precision profiling is critical for the structural integrity of the final panel.

- EPS Block Preparation: EPS foam blocks are typically pre-expanded and cut into specific thicknesses and widths to match the panel design. The density of the EPS core directly influences the panel's thermal and acoustic properties.

- Adhesive Application: A precise layer of high-performance adhesive is applied to the inner surfaces of both profiled steel sheets and to the EPS core. This step is critical, as the quality of the bond directly impacts the panel's durability and structural performance.

- Lamination and Curing: The steel sheets and EPS core are brought together in a continuous laminator, where they are pressed under controlled temperature and pressure. This ensures a strong, uniform bond as the adhesive cures. The continuous motion is a hallmark of a modern eps sandwich panel production line, ensuring high throughput.

- Cutting and Stacking: Once laminated and cured, the continuous panel is cut to predetermined lengths using highly accurate cutting mechanisms. These panels are then stacked and prepared for packaging and dispatch.

Throughout this process, stringent inspection standards, often aligned with ISO 9001 quality management systems, are applied. Critical parameters like panel thickness, adhesion strength, and dimensional accuracy are continuously monitored. The typical service life of an EPS sandwich panel produced on a quality eps panel machine can exceed 30 years, attributed to the durability of its materials and the precision of its manufacturing. Applicable industries range from pre-fabricated building construction to cold storage facilities, industrial workshops, and commercial complexes, where energy efficiency and rapid construction are paramount. Panels provide excellent insulation, reducing heating and cooling costs, and their pre-fabricated nature significantly shortens construction timelines.

Technical Parameters and Specifications of Modern Production Lines

Investing in an eps sandwich panel line requires a thorough understanding of its technical capabilities and specifications. Modern production lines are characterized by their high degree of automation, precise control systems, and ability to handle various material dimensions. Key parameters often include production speed, panel thickness range, effective width, and power consumption. These specifications directly impact throughput, operational costs, and the versatility of the produced panels for different applications.

Below is a typical range of technical parameters for a high-performance eps panel production line, offering insight into what potential buyers should look for when evaluating systems. These figures highlight the capacity and efficiency expected from contemporary machinery, demonstrating significant advancements over previous generations of equipment. It is important to note that these parameters can vary based on the manufacturer and specific customization requirements, offering flexibility to meet diverse project scales and panel specifications.

| Parameter | Typical Range | Unit |

|---|---|---|

| Production Speed | 4-8 | m/min |

| Panel Thickness Range | 50-250 | mm |

| Effective Panel Width | 950-1200 | mm |

| Total Installed Power | 30-60 | kW |

| Adhesive Coating Method | Automatic Two-Component Spraying | - |

| Steel Coil Material | Pre-painted Galvanized Steel, Galvalume | - |

These specifications underline the capability of a modern eps sandwich panel production line to deliver high volumes of diverse panel types, meeting the varying demands of the construction sector. The integration of advanced sensors and control algorithms ensures precise material handling, adhesive application, and curing, leading to consistent product quality and minimal waste.

Applications and Distinct Advantages of EPS Sandwich Panels

The versatility and high performance of EPS sandwich panels, produced efficiently by an eps sandwich panel production line, make them indispensable across a multitude of industries. Their unique composite structure offers a combination of benefits that traditional building materials often cannot match. The core advantages revolve around their superior insulation properties, structural strength, ease of installation, and cost-effectiveness. These attributes contribute to their widespread adoption in various critical sectors.

Key Application Scenarios and Advantages:

- Industrial and Commercial Buildings: From large warehouses and manufacturing plants to shopping malls and office complexes, EPS panels offer rapid construction, excellent thermal regulation, and a clean aesthetic. The thermal conductivity of EPS is typically between 0.032 to 0.038 W/mK, providing substantial energy savings.

- Cold Storage and Food Processing Facilities: Critical for maintaining precise temperature control, EPS panels are ideal for cold rooms and freezers due to their high insulation value and moisture resistance. This significantly reduces operational costs for refrigeration.

- Cleanrooms and Laboratories: The smooth, durable surfaces of EPS panels are easy to clean and maintain, supporting sterile environments required in pharmaceutical, electronics, and biomedical industries.

- Modular and Prefabricated Housing: The lightweight nature and ease of assembly make EPS panels perfect for constructing temporary shelters, site offices, and rapid deployment housing solutions. This also contributes to reduced on-site labor costs and construction time.

- Agricultural Structures: For animal housing, greenhouses, and storage facilities, panels provide necessary climate control and protection against external elements, ensuring optimal conditions.

The technical advantages extend beyond thermal performance. The steel facings provide good structural rigidity and can be coated for enhanced corrosion resistance, making them suitable for environments with high humidity or exposure to chemicals, unlike materials in metallurgy or petrochemical applications that demand different properties. The high strength-to-weight ratio simplifies transportation and installation, further reducing overall project timelines and expenses. Panels are typically non-hygroscopic, resisting moisture absorption and maintaining their insulating properties over time. These combined benefits underscore why an investment in an advanced eps sandwich panel machine is a strategic move for manufacturers looking to cater to a broad and growing market.

Choosing the Right Partner: Manufacturer Comparison and Customization

Selecting the appropriate supplier for an eps sandwich panel production line is a critical decision that impacts long-term operational efficiency and product quality. A thorough evaluation should go beyond initial cost, focusing on technological innovation, after-sales support, customization capabilities, and proven track record. Manufacturers differentiate themselves through the sophistication of their control systems, the robustness of their machinery, and their ability to integrate ancillary equipment for a complete production solution.

Key Considerations for Manufacturer Comparison:

- Technological Sophistication: Look for manufacturers who incorporate advanced PLC (Programmable Logic Controller) systems, precise temperature control, and automated cutting mechanisms. This ensures consistent panel quality and higher efficiency in the eps sandwich panel line.

- Material Compatibility: A versatile line should be able to process different types of steel (e.g., galvanized, Aluzinc, stainless steel) and varying thicknesses, as well as different densities of EPS foam, expanding your product offerings.

- Customization Options: Leading suppliers offer tailored solutions, allowing clients to specify line speed, panel dimensions, and additional features like pre-heating zones or specialized profiling capabilities. This ensures the eps panel machine perfectly aligns with specific production goals.

- After-Sales Service and Support: Assess the availability of technical support, spare parts, and training programs. A reliable manufacturer provides comprehensive assistance, minimizing downtime and ensuring smooth operation. Our commitment includes a robust warranty and accessible customer support.

- Industry Reputation and Experience: Companies with long service years and numerous successful installations (e.g., 10+ years in the industry, serving global clients) often indicate reliability and expertise. Reviewing their portfolio and client testimonials can provide valuable insights.

Furthermore, consider the manufacturer's adherence to international standards like CE or ISO, which signify a commitment to quality and safety. A reputable provider of an eps sandwich panel production line will be transparent about their manufacturing processes, testing protocols, and environmental certifications. Requesting factory visits or detailed technical specifications and component lists can further aid in making an informed decision, ensuring your investment yields optimal returns and long-term operational success.

Ensuring Trust and Reliability: Quality Assurance and Support

In the B2B landscape, trust is paramount, especially when investing in capital equipment like an eps sandwich panel production line. Reputable manufacturers uphold stringent quality assurance protocols and provide robust support systems to ensure client satisfaction and operational longevity. This includes adherence to international standards, comprehensive testing, clear warranty policies, and readily available technical assistance. Transparency in these areas builds confidence and establishes a long-term partnership.

Our Commitment to Quality and Support:

- Industry Certifications and Standards: Our production lines are designed and manufactured in compliance with international quality management systems such as ISO 9001. Key components often carry CE certifications, affirming adherence to European safety and environmental standards. We employ rigorous testing procedures at every stage of the eps panel machine assembly.

- Comprehensive Warranty: We provide a standard warranty period for our eps sandwich panel line, typically covering major components and manufacturing defects. Specific details, including coverage duration and terms, are clearly outlined in our sales agreements, giving you peace of mind regarding your investment.

- Installation and Commissioning: Our experienced technical team can assist with the installation and commissioning of the production line at your facility. This ensures proper setup, calibration, and initial operational stability, allowing you to commence production efficiently.

- After-Sales Support & Training: We offer extensive after-sales support, including remote troubleshooting, on-site technical assistance (if required), and prompt supply of genuine spare parts. Training programs are also available for your operating and maintenance personnel, empowering your team with the necessary expertise for seamless production.

- Delivery Cycle: The typical delivery cycle for a custom eps sandwich panel production line varies based on specific configurations but generally ranges from 60 to 120 working days after contract signing and down payment, allowing for manufacturing, assembly, and rigorous testing.

Our commitment extends to providing detailed user manuals, maintenance guides, and ongoing consultation services. We believe that a strong partnership is built on reliable equipment and dependable support, ensuring your continued success in the insulated panel market. Trust in our proven track record and our dedication to delivering high-performance solutions for your manufacturing needs.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of an EPS sandwich panel produced by your line?

A: With proper installation and maintenance, EPS sandwich panels manufactured on our lines typically have a service life exceeding 30 years. This longevity is attributed to the quality of materials and the precision of the manufacturing process.

- Q: Can your EPS sandwich panel production line produce panels of different thicknesses?

A: Yes, our production lines are designed with adjustable mechanisms to produce panels ranging from 50mm to 250mm in thickness, accommodating diverse project requirements. The changeover between thicknesses is designed to be efficient.

- Q: What kind of steel facings can be used with your eps panel machine?

A: Our lines are compatible with various steel coil types, including pre-painted galvanized steel (PPGI), galvanized steel, and sometimes even stainless steel, depending on the specific model and customization.

- Q: Is training provided for operating the eps sandwich panel line?

A: Absolutely. We offer comprehensive training programs for your operating and maintenance staff, either on-site or at our facility, to ensure your team is fully proficient in running the production line efficiently and safely.

- Q: What are the main benefits of using EPS sandwich panels?

A: Key benefits include excellent thermal insulation (leading to energy savings), lightweight construction, high structural strength, rapid installation, good sound insulation, and fire resistance (with appropriate fire-retardant EPS grades), making them ideal for a wide range of building applications.

Conclusion

The investment in an eps sandwich panel production line represents a strategic move for businesses aiming to capitalize on the growing demand for high-performance, energy-efficient building materials. These advanced manufacturing systems provide the capability to produce versatile, durable, and cost-effective sandwich panels that meet stringent industry standards and diverse application needs. From optimizing production efficiency through automated processes to delivering superior product quality and longevity, a modern eps panel production line is indispensable for maintaining a competitive edge in the construction materials market. By partnering with a reputable manufacturer committed to technological excellence, robust support, and tailored solutions, businesses can ensure long-term success and contribute significantly to sustainable building practices worldwide.

References

- Standards for Thermal Insulation Properties of Building Materials, International Journal of Engineering Sciences.

- Advances in Composite Panel Manufacturing Technology, Journal of Building Materials Research.

- Quality Control and Performance Testing of Sandwich Panels in Construction, Construction and Building Technology Review.

- Sustainable Building Practices and the Role of Insulated Panels, Environmental Science and Sustainable Development.