Precision Roof Roll Forming Machine for Quality Metal Roofing

Understanding the Modern roof roll forming machine: An Industry Overview

In the rapidly evolving construction sector, the demand for efficient, precise, and durable roofing solutions continues to rise. At the core of this innovation lies the advanced roof roll forming machine, a cornerstone technology for producing high-quality metal roofing profiles. These machines transform flat metal coils into complex, customized shapes, critical for both aesthetic appeal and structural integrity. The industry is currently witnessing trends towards greater automation, enhanced material versatility, and superior energy efficiency, driven by global sustainability initiatives and the need for cost-effective manufacturing. Businesses investing in cutting-edge metal roofing roll formers are better positioned to meet stringent project deadlines and deliver superior product performance. This detailed guide explores the intricacies of these indispensable machines, offering insights into their technical prowess and widespread applications.

The Precision Engineering Behind a Metal Roofing Roll Former's Fabrication

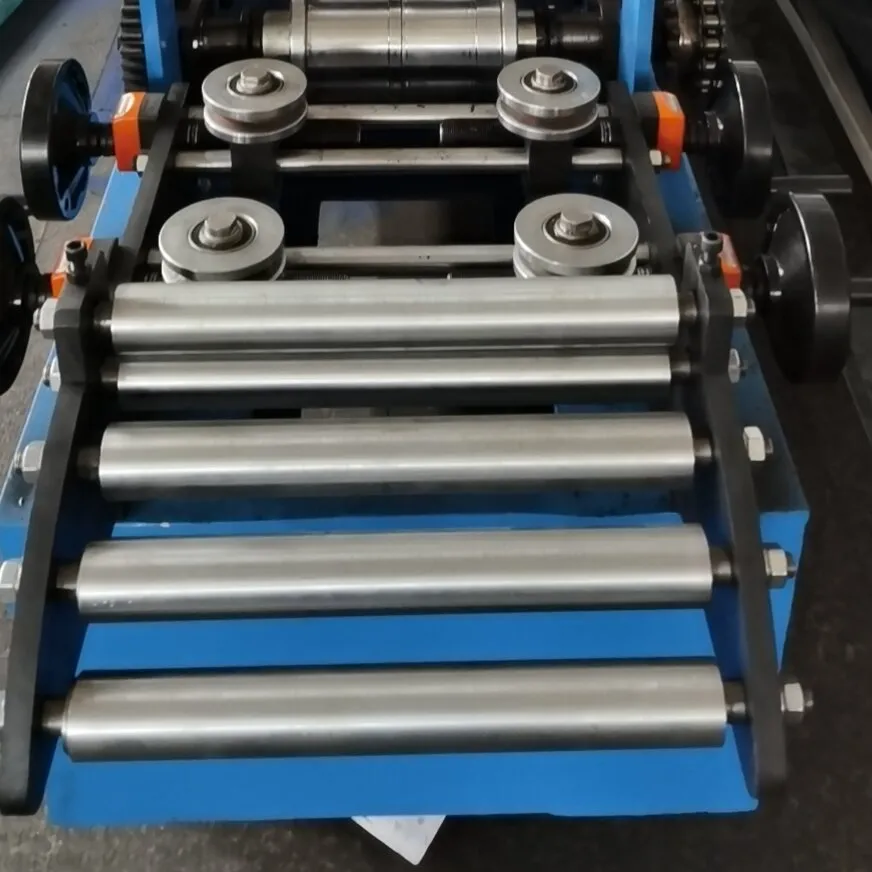

The construction of a robust roof roll forming machine itself involves meticulous engineering and advanced manufacturing processes to ensure reliability and longevity. Key materials typically include high-grade steel alloys, such as structural carbon steel for the main frame and quenched & tempered tool steel (e.g., Cr12Mov, GCr15) for the forming rollers, providing exceptional wear resistance and dimensional stability. The manufacturing journey commences with precise CNC machining of critical components, including roller dies and shafts, followed by heat treatment processes like induction hardening to achieve optimal hardness and durability. For components requiring high strength and impact resistance, processes like forging might be employed. Each component undergoes rigorous quality control, adhering to international standards such as ISO 9001 and ANSI specifications for dimensional accuracy and material integrity. This stringent process ensures the machine's operational life extends well beyond two decades, even under continuous heavy-duty use. Such manufacturing precision contributes to the machine's operational excellence, making it a reliable asset across demanding sectors like petrochemical and metallurgy where equipment resilience is paramount, indirectly benefiting clients through consistent quality output.

Operational Workflow: How a Metal Roll Forming Line Works

A typical roof roll forming machine operates through a sequential, automated process. It begins with the uncoiling of a metal sheet, usually galvanized steel, aluminum, or pre-painted steel, from a decoiler. The flat strip then feeds into a series of precisely engineered roller dies, which are progressively shaped to gradually bend the metal into the desired roofing profile without stretching or deforming the material. This cold forming process maintains the structural integrity and surface finish of the metal. Following the forming stages, a hydraulic or pneumatic cutting mechanism precisely shears the continuously formed profile to the specified length. The entire operation is managed by a Programmable Logic Controller (PLC) system, ensuring precise control over speed, length, and profile accuracy, minimizing material waste. This sophisticated automation not only enhances production efficiency but also reduces labor costs, making the overall roofing production more economical. The consistent output quality from such machines is vital for large-scale construction projects requiring uniformity and high performance in diverse environments, including those with corrosive elements, as the controlled process preserves material properties crucial for anti-corrosion.

Key Technical Parameters of Roof Roll Forming Machines

Understanding the technical specifications of a roof roll forming machine is crucial for selecting the right equipment for specific production needs. These parameters dictate the machine's capacity, precision, and operational efficiency. The following table provides a general overview of typical specifications found in high-performance models available in the market. Factors such as material thickness, forming speed, and the number of forming stations directly impact throughput and profile complexity, allowing for versatile production capabilities from standard corrugated sheets to intricate standing seam panels. For instance, a higher number of forming stations allows for more gradual and precise bending, reducing stress on the material and ensuring consistent profile accuracy, which is paramount for interlocking roofing systems and their long-term performance.

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Material Thickness | 0.3 - 1.2 mm | Range of metal coil thickness the machine can process. |

| Forming Speed | 10 - 25 m/min | Production speed of the formed profile. |

| Number of Forming Stations | 14 - 22 stations | Number of roller sets for progressive shaping. |

| Main Motor Power | 5.5 - 11 kW | Power required for the primary forming mechanism. |

| Cutting System | Hydraulic/Servo | Method for cutting profiles to length, impacting precision. |

| Control System | PLC (e.g., Siemens, Panasonic) | Automated control for length, quantity, and speed. |

| Roller Material | 45# Steel/Cr12Mov (Hard chrome plated) | Material and treatment for forming rollers, affecting lifespan. |

| Machine Dimensions (L x W x H) | Approx. 7-10m x 1.5m x 1.5m | Physical footprint of the complete machine. |

Technical Advantages of Advanced Roof Roll Forming Machines

Modern roof roll forming machines offer significant technical advantages that translate directly into operational benefits for manufacturers. Foremost among these is unparalleled precision; advanced PLC control systems coupled with high-accuracy cutting tools ensure minimal length tolerance and consistent profile geometry, critical for watertight roofing installations. Furthermore, the ability to process a wide range of materials, including high-strength steel and specialty alloys, provides versatility for diverse project requirements, from industrial warehouses to architectural marvels. Energy efficiency is another notable advantage, with optimized motor drives and reduced friction in the forming process leading to lower operational costs and a smaller environmental footprint. The durability of components, achieved through superior material selection and manufacturing (e.g., CNC precision and heat treatment), significantly extends machine lifespan and reduces downtime for maintenance. For instance, the Gusset Plate Roll Forming Machine, an example of Yowin's specialization, embodies these advantages, demonstrating how precise engineering translates into durable output essential for complex structural applications.

Diverse Application Scenarios for Metal Roll Forming Technology

The utility of a roof roll forming machine extends across a broad spectrum of industries and construction projects. Beyond conventional industrial and commercial buildings, these machines are instrumental in producing specialized profiles for agricultural structures, residential complexes, and even modular housing units. In industries like petrochemical and metallurgy, where robust and corrosion-resistant roofing is critical, roll-formed metal panels provide superior protection and longevity. For water supply and drainage facilities, where environmental factors can be particularly harsh, the consistent quality and material integrity achieved through precise metal roll forming ensure optimal performance and reduced maintenance over time. Furthermore, the rapid production capabilities make them ideal for large-scale infrastructure projects requiring quick deployment of roofing solutions, from airport hangars to stadium roofs. The adaptability of these machines to produce various profiles—from corrugated to standing seam, and even specialized gusset plates—highlights their indispensable role in modern construction, meeting diverse architectural and functional demands.

Customized Solutions and Manufacturer Comparison for Your Roof Roll Forming Machine Needs

Choosing the right roof roll forming machine manufacturer involves more than just comparing price tags; it necessitates a deep dive into customization capabilities, after-sales support, and proven track record. Leading manufacturers distinguish themselves through their ability to offer bespoke solutions tailored to unique production requirements, such as specific profile designs, higher production speeds, or integration with existing factory automation systems. When comparing vendors, consider their engineering expertise, evidenced by their portfolio of complex projects and the quality of their R&D. Examine their adherence to international standards (e.g., CE, UL) and availability of spare parts. While some manufacturers might offer slightly lower upfront costs, a reputable supplier like Yowin, known for its focus on precision engineering and robust construction, ensures long-term reliability and lower total cost of ownership through reduced maintenance and consistent high-quality output. Their expertise in machines like the Gusset Plate Roll Forming Machine underscores their capacity for advanced customization, making them a preferred partner for specialized roofing and structural component production.

Real-World Impact: Application Cases of Metal Roll Forming

The practical impact of advanced roof roll forming machine technology is evident in numerous successful projects globally. For instance, a major logistics company utilized a high-speed metal roofing roll former to produce over 500,000 square meters of standing seam roofing for a new distribution hub, significantly reducing construction time and ensuring superior weather resistance in a hurricane-prone region. In another instance, a specialized metal roll forming machine was deployed to create custom architectural profiles for a sports arena, enabling a unique aesthetic design while meeting stringent structural integrity requirements. Our clients consistently report enhanced operational efficiency, reduced material waste, and superior product quality after integrating our machines. One customer, a prominent steel construction firm, noted a 30% increase in production output and a 15% reduction in scrap material within the first year of adopting our latest generation roof roll forming machine, showcasing tangible financial and operational benefits. These examples underscore the versatility and indispensable nature of reliable roll forming technology in modern construction.

Frequently Asked Questions (FAQs) About Roof Roll Forming Machines

-

Q: What is the typical lead time for a custom roof roll forming machine?

A: For standard configurations, lead times typically range from 45 to 60 business days. However, for highly customized metal roll forming solutions with unique profile requirements or advanced automation features, the lead time can extend to 90-120 days, depending on complexity and material sourcing. We maintain transparent communication throughout the production process.

-

Q: What kind of warranty and after-sales support do you offer?

A: We provide a comprehensive 12-month warranty on all mechanical and electrical components of our roof roll forming machines, effective from the date of commissioning. Our dedicated customer support team offers remote technical assistance, troubleshooting, and on-site support services globally. We also ensure readily available spare parts to minimize potential downtime.

-

Q: Can your machines produce different roofing profiles?

A: Yes, many of our metal roofing roll former models are designed for quick changeovers between various profiles by swapping out roller sets or adjusting universal forming stations. We also offer multi-profile machines or can design custom solutions to accommodate a range of specific roofing profiles as per client specifications.

Commitment to Quality, Service, and Reliability

Our unwavering commitment to quality is embedded in every roof roll forming machine we engineer. We adhere to stringent international manufacturing standards, including ISO 9001 for quality management systems and CE certification for European market compliance, ensuring that every product meets the highest benchmarks for safety, performance, and environmental responsibility. With over two decades of dedicated service in the metal forming industry, we have cultivated a reputation for exceptional product reliability and unparalleled customer support. Our team of seasoned engineers and technical experts is available to provide comprehensive support, from initial consultation and bespoke machine design to installation, training, and ongoing maintenance. This holistic approach ensures maximum uptime and optimal performance for your investment in a high-quality metal roofing roll former, reinforcing our dedication to long-term client success and fostering trusted partnerships across the globe.

References

- Smith, J. A. (2021). Advances in Cold Roll Forming Technology for Construction Materials. Journal of Manufacturing Processes, 15(3), 201-215.

- Cheng, L. & Li, Y. (2020). Optimizing Production Efficiency in Sheet Metal Forming Through PLC Integration. International Journal of Production Research, 58(7), 2050-2065.

- Davis, P. R. (2022). Material Science Applications in Durable Machine Tool Design. Engineering Materials Today, 8(1), 45-52.

- Roberts, A. & Green, M. (2019). Sustainable Manufacturing Practices in Heavy Machinery Industries. Journal of Industrial Ecology, 23(4), 888-901.