Trusted Roll Forming Machine Manufacturers | Quality & Price

Innovating Precision: The Pivotal Role of Leading Roll Forming Machine Manufacturers in Modern Industry

In the fiercely competitive landscape of modern manufacturing, precision, efficiency, and material optimization are paramount. At the heart of achieving these critical objectives lies the advanced technology of roll forming. This sophisticated cold-forming process transforms flat sheets of metal into complex profiles of uniform cross-section, offering unparalleled advantages in terms of structural integrity, cost-effectiveness, and design flexibility. The demand for high-quality, reliable machinery has consequently propelled the significance of expert roll forming machine manufacturers. These specialized entities are not merely equipment suppliers; they are crucial partners in industries ranging from construction and automotive to renewable energy and infrastructure, providing the foundational tools that shape tomorrow's world. Their expertise spans the entire lifecycle of machine development, from conceptual design and material selection to precision engineering and post-installation support. As global industries increasingly prioritize sustainable practices and enhanced performance, the role of innovative roll forming technology becomes even more critical, driving advancements in both product design and production methodologies. This article delves into the intricate world of roll forming, highlighting the key considerations, technological breakthroughs, and strategic importance of choosing the right manufacturing partner for your specific industrial needs, ensuring that your production capabilities are not just met, but exceeded, through superior machinery and comprehensive service offerings, underpinning long-term operational success and market competitiveness in a rapidly evolving global economy.

The Core of Roll Forming Technology: Principles and Industrial Impact

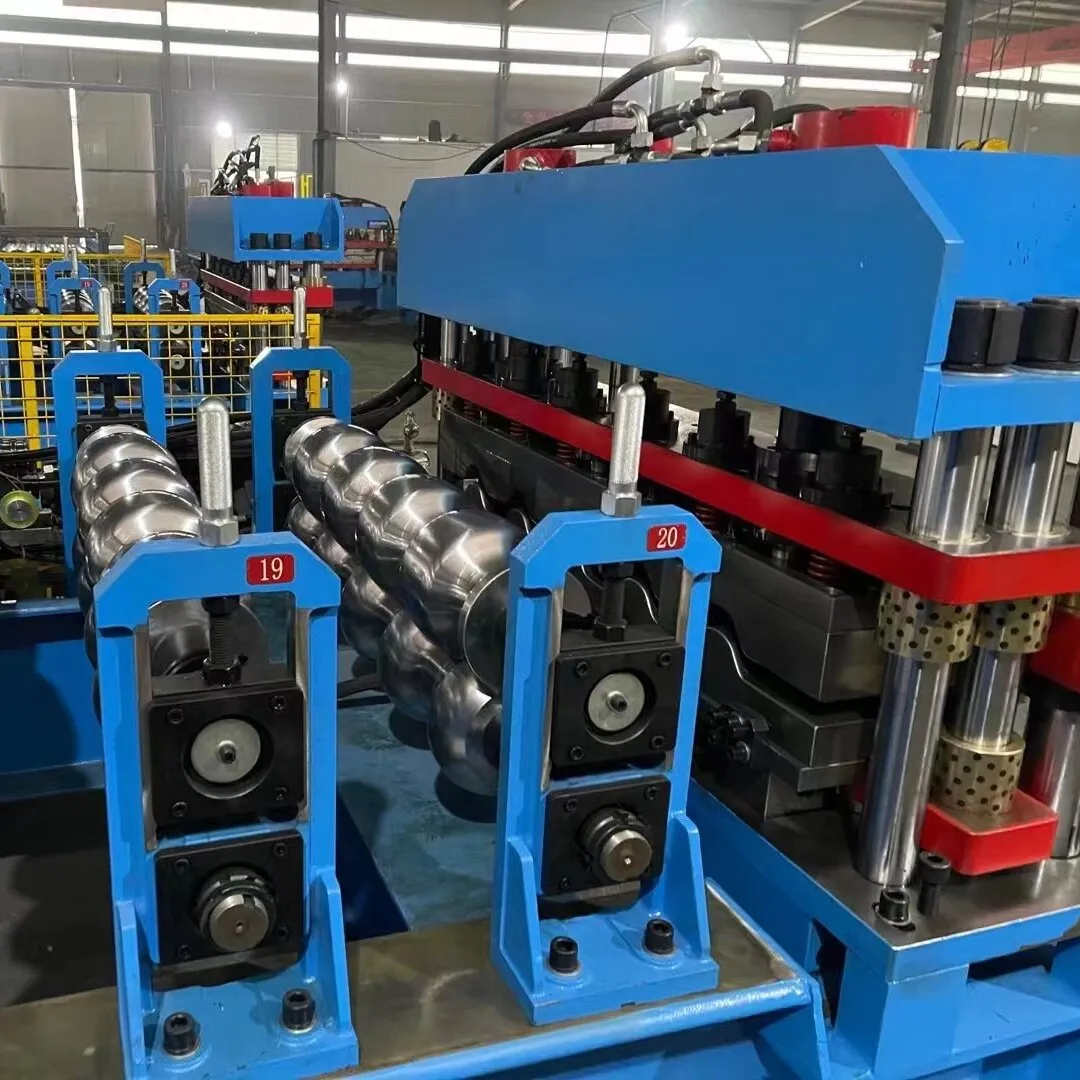

Roll forming is a continuous bending operation in which a long strip of metal, typically coil stock, passes through successive sets of rolls, each set performing an incremental part of the bend until the desired cross-sectional profile is obtained. Unlike other metal forming processes such as press braking or stamping, roll forming is ideal for producing parts with high dimensional accuracy, excellent surface finish, and consistent cross-sections over extended lengths. This inherent consistency makes it invaluable for applications where uniformity is critical, such as structural components, roofing panels, and automotive parts. The process begins with an uncoiler, which feeds the metal strip into the machine. Subsequent stages involve guiding and forming rolls, which progressively shape the material. The precision of these rolls, often manufactured to tolerances of less than 0.01 mm, is paramount to the final product's quality. Advanced control systems, including PLC-based automation and servo-driven mechanisms, ensure precise speed synchronization and profile accuracy, minimizing material waste and maximizing throughput. Furthermore, modern roll forming lines can integrate punching, notching, and cutting operations in-line, creating a highly efficient, single-pass manufacturing solution. This integration significantly reduces secondary operations, labor costs, and overall production time, positioning roll forming as a highly cost-effective method for high-volume production runs. The ability to handle a wide range of materials, including various grades of steel, aluminum, and even non-ferrous alloys, further expands its applicability across diverse industrial sectors, making it a cornerstone technology for sophisticated metal fabrication requirements.

Manufacturing Excellence: A Look at the Process of Leading Roll Forming Machine Manufacturers

The journey of a roll forming machine, from raw material to a fully operational production powerhouse, embodies a meticulous multi-stage manufacturing process, showcasing the pinnacle of engineering expertise from top roll forming machine manufacturers. It commences with the careful selection of high-grade raw materials, typically structural steel alloys for the main frame and high-strength tool steel (e.g., D2 steel, Cr12MoV) for the precision-engineered rolls. This material choice is critical, ensuring machine longevity, resistance to wear, and consistent performance under rigorous industrial conditions. The core components, such as shafts and gearboxes, often undergo sophisticated manufacturing processes like precision casting or closed-die forging to achieve superior mechanical properties and structural integrity, followed by meticulous CNC machining to achieve micron-level tolerances. Heat treatment processes, including quenching and tempering, are then applied to enhance the hardness and durability of critical wear parts. Each component, from the forming rollers to the cutting dies, undergoes stringent quality control inspections, adhering to international standards such as ISO 9001 for quality management and ANSI standards for dimensional accuracy and performance, a hallmark of diligent roll forming machine manufacturers. For example, the gears within a gearbox, critical for transmitting power smoothly and efficiently, are often carburized and precision-ground to achieve HRC 58-62 hardness, ensuring minimal backlash and extended operational life. The typical service life of a well-maintained roll forming machine can exceed 20 years, a testament to the robust design and manufacturing quality championed by reputable roll forming machine manufacturers. These machines are extensively utilized in industries like petrochemical (for piping and structural supports), metallurgy (for custom profiles), and water supply/drainage (for specialized conduit and paneling), offering significant advantages such as energy efficiency through optimized power consumption, and superior corrosion resistance when handling pre-coated or galvanized materials. The integration of advanced sensors and real-time monitoring systems further ensures that the machine operates within optimal parameters, minimizing downtime and maximizing productivity in high-demand environments for leading global roll forming machine manufacturers.

Key Technical Parameters and Performance Metrics: What Distinguishes Top Roll Forming Machine Suppliers

When evaluating a roll forming machine supplier, understanding the critical technical parameters and performance metrics is essential for making an informed investment. These specifications directly impact the machine's efficiency, versatility, and the quality of the final product. Key parameters include the machine's forming speed, which can range from 10 to 60 meters per minute depending on the profile complexity and material thickness; the maximum material thickness and width it can process; and the number of forming stations, which dictates the complexity of profiles it can achieve. Power consumption, expressed in kilowatts (kW), is another vital metric, reflecting operational costs and energy efficiency, with advanced machines often featuring energy-saving servo motors. The material compatibility is also crucial, as machines are often optimized for specific materials such as galvanized steel, pre-painted steel, aluminum, or stainless steel. Furthermore, the control system's sophistication, whether basic PLC or advanced CNC with integrated HMI, significantly impacts ease of operation, diagnostic capabilities, and precision, a critical distinction among leading roll forming machine manufacturers. Lubrication systems, often automatic or semi-automatic, ensure the longevity of moving parts. A robust gearbox, especially for machines like the Roof Sheet Roll Forming Machine With Gear Box, ensures stable power transmission and reduced maintenance. The following table provides a comparative overview of typical parameters found in high-performance roll forming machines, helping potential buyers assess the capabilities of different models from various roll forming machine manufacturers and align them with their specific production requirements and desired output quality.

| Parameter | Unit | Typical Range (Standard) | Premium/Customized (Example: Roof Sheet Machine) |

|---|---|---|---|

| Forming Speed | m/min | 10 - 30 | 20 - 60 (with servo drive) |

| Material Thickness | mm | 0.3 - 1.2 | 0.25 - 1.5 (specifically for roofing) |

| Number of Forming Stations | Stages | 12 - 18 | 16 - 24 (for complex profiles) |

| Main Motor Power | kW | 5.5 - 11 | 7.5 - 18.5 (often with gearbox) |

| Material Width | mm | 914 - 1250 | up to 1500 (customizable) |

| Roll Material | Type | 45# Steel, Cr12 | GCR15, D2 Steel (quenched, polished) |

| Control System | Type | PLC (Delta/Siemens) | Advanced PLC + HMI Touch Screen |

| Dimension Accuracy | Tolerance | ±0.5mm | ±0.25mm (length & width) |

Applications Across Industries: Where Our Machines Make a Difference

The versatility of roll forming technology positions it as an indispensable asset across a multitude of industries, driving innovation and efficiency in diverse applications. For instance, our Roof Sheet Roll Forming Machine With Gear Box is specifically engineered to produce high-quality roofing and wall panels, a critical component in the construction sector. These machines are integral to large-scale infrastructure projects, commercial buildings, and residential developments, providing durable, weather-resistant, and aesthetically pleasing solutions. Beyond construction, roll forming machines are pivotal in the automotive industry for manufacturing chassis components, structural beams, and impact absorption parts, where precise tolerances and high strength-to-weight ratios are paramount. In the renewable energy sector, they produce structural elements for solar panel mounting systems and wind turbine towers, demonstrating their capacity to handle demanding specifications for sustainable technologies. The agricultural industry benefits from roll formed sections for grain silos, fencing, and equipment frames, where robust and long-lasting components are essential. Storage solutions, including shelving systems and pallet racks, also heavily rely on roll forming for producing high-capacity, space-efficient structures. The process's ability to create custom profiles economically makes it ideal for specialized applications like custom architectural elements, industrial shelving, and even complex sections for aerospace components. Many leading roll forming machine manufacturers often work closely with clients to develop bespoke profiles for unique applications, ensuring that the machinery meets exact operational demands, whether it’s for producing corrugated sheets, C-channels, Z-sections, or intricate custom shapes, thereby unlocking new possibilities for product design and market differentiation. This broad spectrum of applications underscores the fundamental role of roll forming in modern industrial production, providing reliable and efficient solutions for shaping the materials of progress.

Unveiling the Advantages: Why Choose Advanced Roll Forming Solutions?

Opting for advanced roll forming solutions from reputable roll forming machine manufacturers offers a compelling array of technical and economic advantages over conventional metal forming methods. Foremost among these is the unparalleled consistency and accuracy of the produced profiles. Unlike press braking, which bends discrete lengths, roll forming creates continuous profiles with uniform cross-sections, minimizing variations and ensuring precise fit and finish, crucial for assembly and structural integrity. This high degree of precision is maintained even at high production speeds, making it exceptionally efficient for large volume orders. Furthermore, roll forming is a cold forming process, meaning it shapes metal without heating, thereby preserving the material's mechanical properties and avoiding the metallurgical changes that can occur with hot working. This often results in stronger, lighter parts with improved yield strength due to work hardening. The process is also highly material-efficient, producing minimal scrap compared to stamping or machining, which contributes to significant cost savings and aligns with sustainable manufacturing practices. The integration of advanced automation, such as automatic cutting-to-length and punching systems, further enhances productivity and reduces labor dependency. Machines equipped with features like a robust gearbox, as seen in our Roof Sheet Roll Forming Machine With Gear Box, deliver stable and consistent power transmission, reducing wear and tear on components and ensuring reliable long-term operation. The ability to handle pre-painted or coated materials without damaging the surface finish is another significant advantage, eliminating the need for post-forming painting and reducing production time and costs. These combined technical advantages translate directly into lower unit costs, faster turnaround times, and superior product quality, providing a significant competitive edge in the marketplace for any enterprise investing in this cutting-edge technology from trusted roll forming machine manufacturers. This efficiency is a hallmark of products from leading roll forming machine manufacturers.

Customization and Comprehensive Support: Partnership with Leading Roll Forming Machine Manufacturers

Beyond standardized machinery, the true value of partnering with top-tier roll forming machine manufacturers lies in their capacity for customization and comprehensive post-sales support. Recognizing that each client possesses unique production requirements, leading suppliers offer tailored solutions, designing machines that perfectly align with specific material types, profile geometries, and output capacities. This bespoke approach ensures optimal performance and seamless integration into existing production lines. Our expertise, honed over more than 15 years in the industry, allows us to deliver machines with precise specifications, ensuring that the investment yields maximum returns. For example, a client requiring specific anti-capillary grooves on their roofing sheets, or a unique fastening system, can have these features integrated directly into the roll design and cutting process, enhancing product functionality and reducing assembly time. This is a distinguishing feature of truly client-focused roll forming machine manufacturers. Our commitment extends far beyond the point of sale. We provide extensive pre-sales consultation, detailed engineering design, manufacturing, quality control, installation, and commissioning services. Our delivery cycle is meticulously managed, typically ranging from 45 to 90 days depending on machine complexity and customization, ensuring timely project execution. After delivery, we offer robust technical support, including remote diagnostics, on-site assistance, and comprehensive training programs for your operators and maintenance staff. Our machines come with a standard 12-month warranty on mechanical parts and a 6-month warranty for electrical components, with extended options available. Customer feedback consistently highlights our prompt response times and effective problem-solving capabilities, transforming transactional relationships into long-term partnerships built on trust and mutual success. This holistic support system is crucial for minimizing downtime, maximizing machine uptime, and ensuring that your investment in a roll forming machine from professional roll forming machine manufacturers remains highly productive throughout its extended operational lifespan.

Ensuring Trust and Authority: Our Commitment to Quality and Compliance

Establishing trust and authority is fundamental for any leading roll forming machine supplier, and it is achieved through unwavering commitment to quality, adherence to international standards, and transparent operational practices. Our manufacturing processes are rigorously controlled and certified to ISO 9001:2015, ensuring a systematic approach to quality management from design to delivery. This certification is a testament to our dedication to continuous improvement and customer satisfaction. Furthermore, our machines comply with relevant safety and performance standards such as CE marking for European markets, and where applicable, industry-specific standards like those set by ASTM for steel products or specific building codes. We pride ourselves on transparent testing protocols: every machine undergoes extensive factory acceptance testing (FAT) before shipment, where performance metrics, dimensional accuracy, and operational stability are meticulously verified. Clients are often invited to witness these tests, providing full visibility and assurance of the machine's capabilities. Our long-standing partnerships with global enterprises, including major construction firms and automotive component suppliers, underscore our reliability and proven track record. With over a decade of dedicated service in the roll forming industry, our accumulated experience translates into profound technical knowledge and problem-solving capabilities. We maintain a comprehensive database of test data and performance benchmarks for various machine models and profiles, enabling us to provide data-backed assurances regarding expected output and efficiency. Our engineering team comprises certified professionals with deep expertise in mechanical design, electrical engineering, and automation, ensuring that every machine represents the pinnacle of current technological advancement. This robust framework of certifications, partnerships, extensive testing, and expert personnel solidifies our position as an authoritative and trustworthy source for high-performance roll forming solutions, reinforcing the value proposition for every client considering their next significant capital investment from experienced roll forming machine manufacturers. Our commitment to these values positions us as a prime example among reliable roll forming machine manufacturers.

Understanding Your Investment: Insights into Roll Forming Machine Price and Value

The roll forming machine price is a critical factor for any potential buyer, yet it's imperative to view this cost not just as an expenditure but as a strategic investment that delivers long-term value and competitive advantage. The price can vary significantly based on several factors, including the machine's complexity, automation level, processing speed, material compatibility, and the degree of customization required. Entry-level machines for basic profiles might range from tens of thousands of dollars, while highly automated, multi-profile lines with integrated punching and stacking systems can ascend into hundreds of thousands. Investing in a machine from reputable roll forming machine manufacturers often means a higher initial outlay, but this is typically offset by superior build quality, enhanced reliability, reduced downtime, lower maintenance costs, and a significantly longer operational lifespan. Moreover, factors such as energy efficiency, material yield optimization, and the ability to produce high-precision components directly contribute to lower operational expenses and increased profitability over the machine's lifetime. Prospective buyers should consider the total cost of ownership (TCO), which encompasses not only the purchase price but also installation, training, power consumption, maintenance, and potential productivity gains. For example, a machine capable of higher forming speeds or processing wider materials can dramatically increase output, leading to a quicker return on investment (ROI). Furthermore, the quality of after-sales support and the availability of spare parts from your chosen roll forming machine supplier can significantly influence the machine's long-term operational costs and overall value. This also extends to the long-term support provided by experienced roll forming machine manufacturers. A comprehensive understanding of these factors allows for a more accurate assessment of the true value proposition, ensuring that the chosen roll forming solution is not just affordable but economically superior in the long run, thereby optimizing your operational budget and future growth trajectory.

Frequently Asked Questions (FAQ) about Roll Forming Machines

Q1: What is the typical lead time for a customized roll forming machine?

A1: The lead time for a customized roll forming machine can vary based on the complexity of the design and the specific components required. Generally, it ranges from 45 to 90 working days from the confirmation of the order and technical specifications. This period includes design, material sourcing, manufacturing, assembly, rigorous quality control testing, and final packaging. For standard models, the lead time might be shorter, typically between 30 to 60 days. We provide a detailed project timeline upon order confirmation, ensuring full transparency in our delivery process, a practice common among reliable roll forming machine manufacturers.

Q2: What kind of after-sales support and warranty do you offer?

A2: We offer comprehensive after-sales support to ensure the continuous and efficient operation of your machine. This includes remote technical assistance via phone or video call, on-site installation and commissioning services (subject to agreement), and training programs for your operating and maintenance personnel. Our machines come with a standard 12-month warranty covering mechanical parts and a 6-month warranty for electrical components, effective from the date of shipment. We also provide readily available spare parts and can arrange for extended warranty agreements based on client needs, demonstrating our commitment to long-term client satisfaction and machine reliability, a key differentiator among leading roll forming machine suppliers.

Q3: Can your machines process different types of metal materials?

A3: Yes, our roll forming machines are designed with versatility in mind and can be configured to process a wide range of metal materials. This includes various grades of steel (e.g., galvanized steel, pre-painted steel, cold-rolled steel, stainless steel), aluminum, and some non-ferrous alloys. The specific capabilities depend on the machine model, the design of the forming rolls, and the power of the drive system. When requesting a quote or designing a custom machine, it is crucial to specify the types and thicknesses of materials you intend to process, as this informs the selection of appropriate roll materials, machine frame strength, and motor specifications to ensure optimal performance and longevity. Our engineering team can provide expert guidance on material compatibility and machine configuration to meet your specific production requirements, ensuring the chosen machine is perfectly suited for your operational needs and material types, a common offering from experienced roll forming machine manufacturers.

Conclusion: Partnering for Future Success with Expert Roll Forming Machine Manufacturers

In conclusion, the strategic importance of selecting the right roll forming machine manufacturers cannot be overstated. These key partners are instrumental in providing the advanced machinery that underpins efficient, precise, and high-volume metal profile production across a myriad of global industries. From the meticulous manufacturing processes involving high-grade materials and precision engineering to the integration of advanced automation and comprehensive after-sales support, every aspect contributes to the long-term success of your operations. Our dedicated focus on delivering cutting-edge solutions, exemplified by products like the Roof Sheet Roll Forming Machine With Gear Box, combined with our commitment to quality, adherence to international standards, and extensive customer support, positions us as a trusted and authoritative roll forming machine supplier. We emphasize the value of understanding not just the initial roll forming machine price, but the total cost of ownership and the substantial return on investment derived from superior machine performance, minimal downtime, and optimized material utilization. As industries continue to evolve, demanding greater efficiency, customizability, and sustainability, partnering with an experienced and reliable roll forming machine manufacturers ensures that your production capabilities remain at the forefront, ready to meet future challenges and capitalize on emerging opportunities, thereby securing a competitive advantage and fostering sustained growth in a dynamic market landscape.

References

- Doege, E., & Neugebauer, R. (2012). Handbook of Sheet Metal Forming: Basic Principles, Applications, and Press Technologies. Springer Science & Business Media.

- Hosford, W. F., & Caddell, R. M. (2011). Metal Forming: Mechanics and Metallurgy. Cambridge University Press.

- Davies, R. (2000). Roll Forming Handbook. McGraw-Hill Professional.

- Altan, T., & Tekkaya, A. E. (2012). Sheet Metal Forming: Fundamentals. ASM International.

- Groche, P. (2019). Roll Forming of Lightweight Structures. CRC Press.