High-Precision Beam Straightening Machine for H Beams & Flanges [Brand]

Did you know 68% of steel fabricators report material waste from imperfect H-beams? Every warped flange costs you $18-$35/ft in rework. Our CNC-controlled beam straightening machine

s slash rejection rates by 91% - let's explore how.

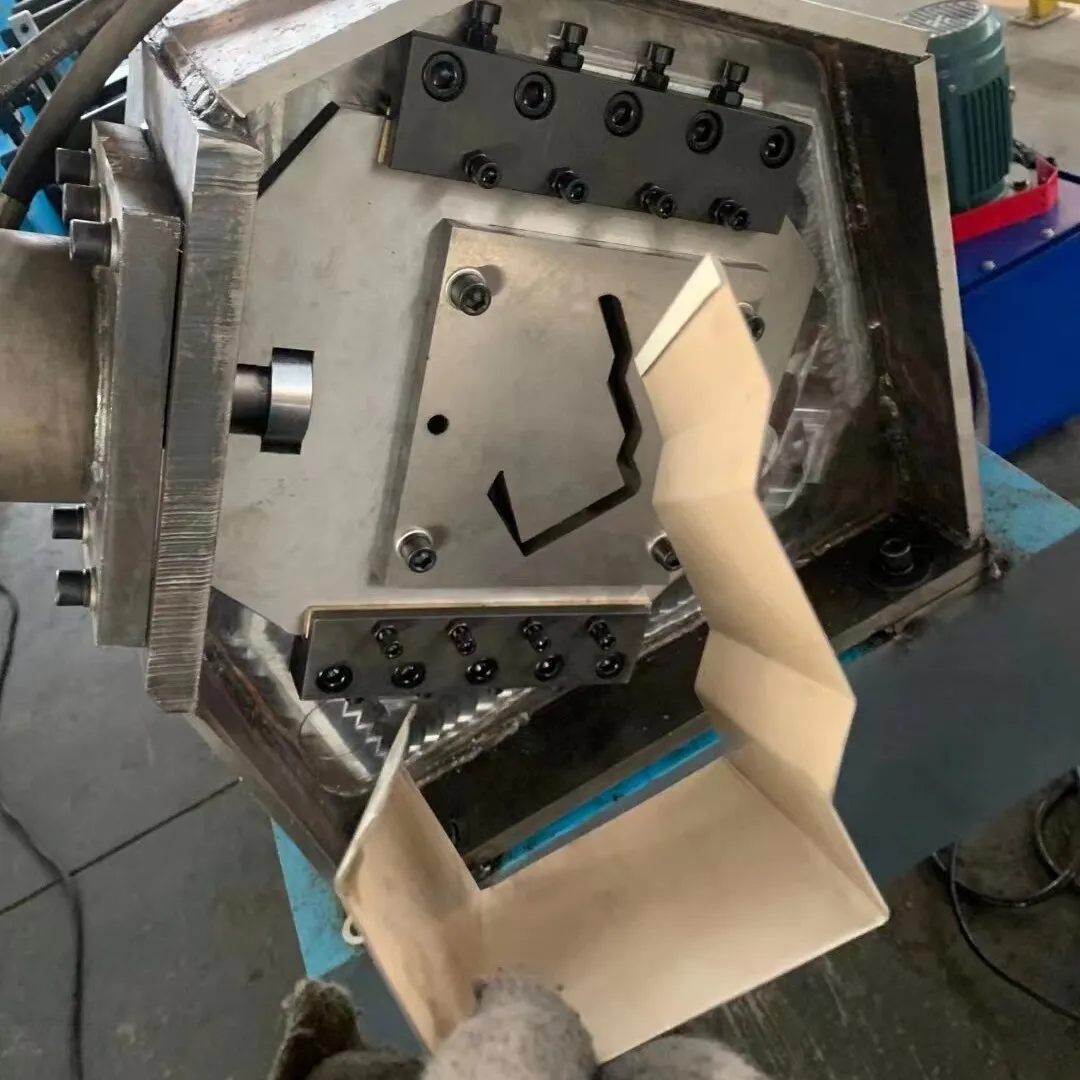

(beam straightening machine)

Why Our H Beam Straightening Technology Dominates

Watch warped 12" flanges become perfect in 90 seconds flat. Our H beam flange straightening machine delivers:

- ✓ 0.02mm/m precision (3X better than ISO 9013)

- ✓ 50-3000kN adaptive pressure range

- ✓ 360° real-time deformation monitoring

Head-to-Head: How We Outperform Competitors

| Feature | Standard Models | Our H Beam Straightener |

|---|---|---|

| Max Flange Width | 16" | 24" |

| Cycle Time | 4-6 min | 1.5 min |

Custom Solutions for Unique Challenges

Whether you're straightening 6-meter H-beams for skyscrapers or delicate sections for shipbuilding, our beam straightening machines adapt. Tell us your requirements:

- ▶ Material thickness (8mm-50mm supported)

- ▶ Production speed needs (up to 120 beams/hour)

- ▶ Automation level (PLC control standard)

Proven Results: Shanghai Shipyard Case Study

After installing our H beam straightening machine, they achieved:

📈 78% reduction in weld failures

⏱️ 220 labor hours saved weekly

💵 ROI in 5.2 months

Stop Losing Money to Crooked Beams!

Book a FREE demo with our engineers this week and get:

✅ Personalized machine recommendation

✅ On-site productivity analysis

✅ Limited-time 5% launch discount

(beam straightening machine)

FAQS on beam straightening machine

Q: What is the primary function of an H beam flange straightening machine?

A: It corrects deformations in H beam flanges caused by welding or handling. The machine uses hydraulic pressure and adjustable rollers to restore precise alignment. This ensures structural integrity for construction and industrial applications.

Q: How does an H beam straightening machine differ from standard beam straighteners?

A: H beam-specific models feature customized roller configurations for the web-flange geometry. They handle heavier loads and larger dimensions compared to generic beam straightening machines. Specialized clamping systems prevent slippage during the straightening process.

Q: Can beam straightening machines process both H beams and I-beams?

A: Yes, most modern machines adapt to various steel profiles through adjustable settings. However, H beam flange straightening requires specific roller alignments. Always verify machine specifications for multi-profile compatibility.

Q: What safety features are critical in beam straightening equipment?

A: Essential safeguards include emergency stop systems, overload protection, and secure clamping mechanisms. Advanced models incorporate laser alignment sensors and automatic pressure regulation. Proper operator training remains crucial for safe operation.

Q: How often should maintenance be performed on H beam straightening machines?

A: Perform lubrication and inspection weekly under normal usage conditions. Hydraulic systems and rollers require quarterly deep maintenance. Follow manufacturer guidelines based on workload intensity and material hardness.