|

Manual Decoiler

1.Passive feed, manually tighten manually

2.Capacity: 3T

3.The inner diameter: φ508mm

4.Range range: φ480-520mm

|

|

|

Feeding system

It is set at the beginning of the host to help the operator correctly adjust the direction of the inlet board. You can adjust the left and right side by hand wheels, and the number of feed is displayed.

|

|

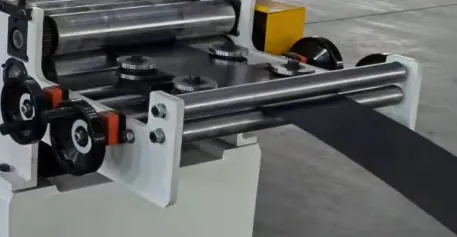

Leveling machine

1.Roller: up 2 down 3

2.Roller material: 40Cr, chrome -plated

3.Equipped on the molding machine

4.Motor: 3KW

5.Diameter: φ80mm

|

|

|

- Hydrauic pre-cutting

-

1.Working form: Hydraulic shear; stop cutting; no waste

2.Blade material: CR12Mov, HRC> 62 °

3.Blade 1

|

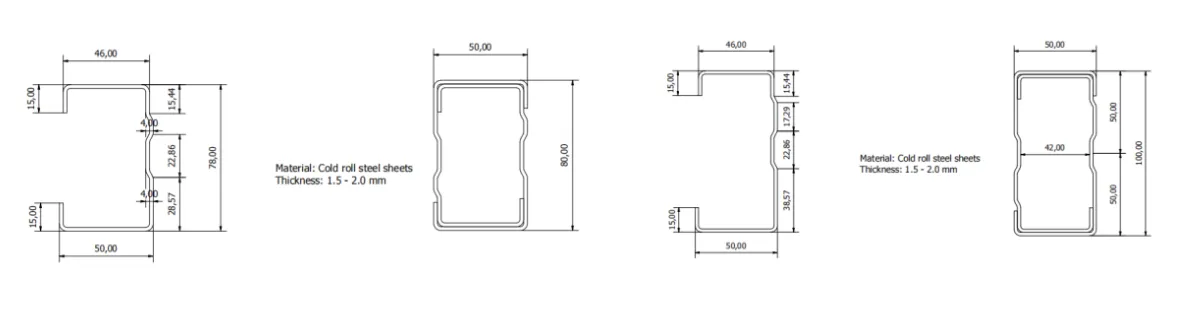

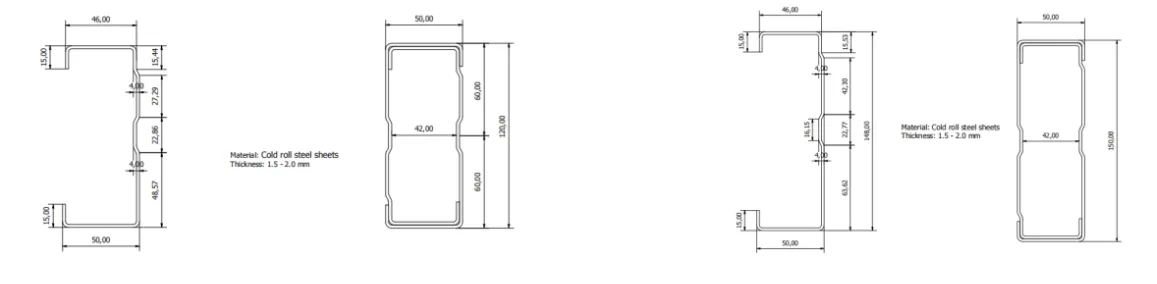

- Main roll forming machine

-

- 1. Material thickness range: 5-2.5mm

- 2. Main motor power:15kw

3.Horizontal motor power: 1 × 1.5kW

- Forming speed: 0-15m/min

- Quantity of stands: about 16

6.Material of forming rollers: Cr12

- Shaft Material and diameter: ¢90mm-¢110

material :40Cr quenching and tempering treatment (HB220-260)

8.Controlling system: PLC

- 9. Voltage: 380V/ 3phase/ 60 Hz

- 10. Roll heat treatment method: quenching treatment (HRC58-62)

11.Model Form: Archway Chain Transmission

12.Roller pilot form: use both sides of the roller split type, the main axis inserted transmission

|

|

|

- Hydraulic cutting system

-

1.Working method: hydraulic shear, servo tracking

2.Servo motor: 3KW,

3.Thickness waste: no waste

4.Scissors Material Material: CR12Mov, SKD11, HRC> 62 °

5.Number of blades: 4 knives (different specifications for knives)

6.Level Code Brand: KOYO (Japan)

7.Hydraulic power: 7.5kW

|

- Conveyor flip table

-

1.Transmission method: chain transmission

2.Electric power: 2.2KW × 3

3.Platform size: 6 meters long according to the length of the shear

4.Platform function: flip

|

|

|

- Embrace machine

-

1.Body structure: archway structure

2.Model Motor: 5.5KW

3.The bottom width is automatically moved by the motor after setting on the touch screen

4.Horizontal motor power: 1.5kW*1

5.Transmission method: chain transmission

6.Number of molding roads: 5

7.Wheel material: GCR15, quenching

8.Axial diameter: φ80mm

9.Molding speed: 0-15m/min,

10.There is a separate control cabinet in a bite formation machine

|

- Receiving table

-

2000mm*2 Simple and powerless (corner steel welding, drum custard)

|

|

|

- PLC Control system

-

1.Inverter: Anchuan (Japan)

2.PLC: Siemens

3.Computer operating panel: MCGS

4.Coder: Omron/Optical Ocean

5.Voltage; 380V, 50Hz, 3PH (can be according to customer requirements)

|