Light Gauge Steel Villa Roll Forming Machine is a specialized piece of equipment designed to manufacture light gauge steel components used in the construction of villas and other residential buildings. This machine processes steel coils into various shapes and profiles, which are then used for framing, roofing, and other structural applications. The roll forming process ensures precision and consistency in the production of steel components, making it an essential tool for modern construction.

Using a Light Gauge Steel Villa Roll Forming Machine offers several advantages, including:

- Efficiency: The machine automates the production process, significantly reducing labor costs and time.

- Precision: It produces uniform and accurate steel profiles, ensuring high-quality construction materials.

- Durability: Light gauge steel is resistant to pests, rot, and fire, making it a long-lasting choice for building structures.

Flexibility: The machine can be adjusted to create various profiles, allowing for customization based on specific project requirements.

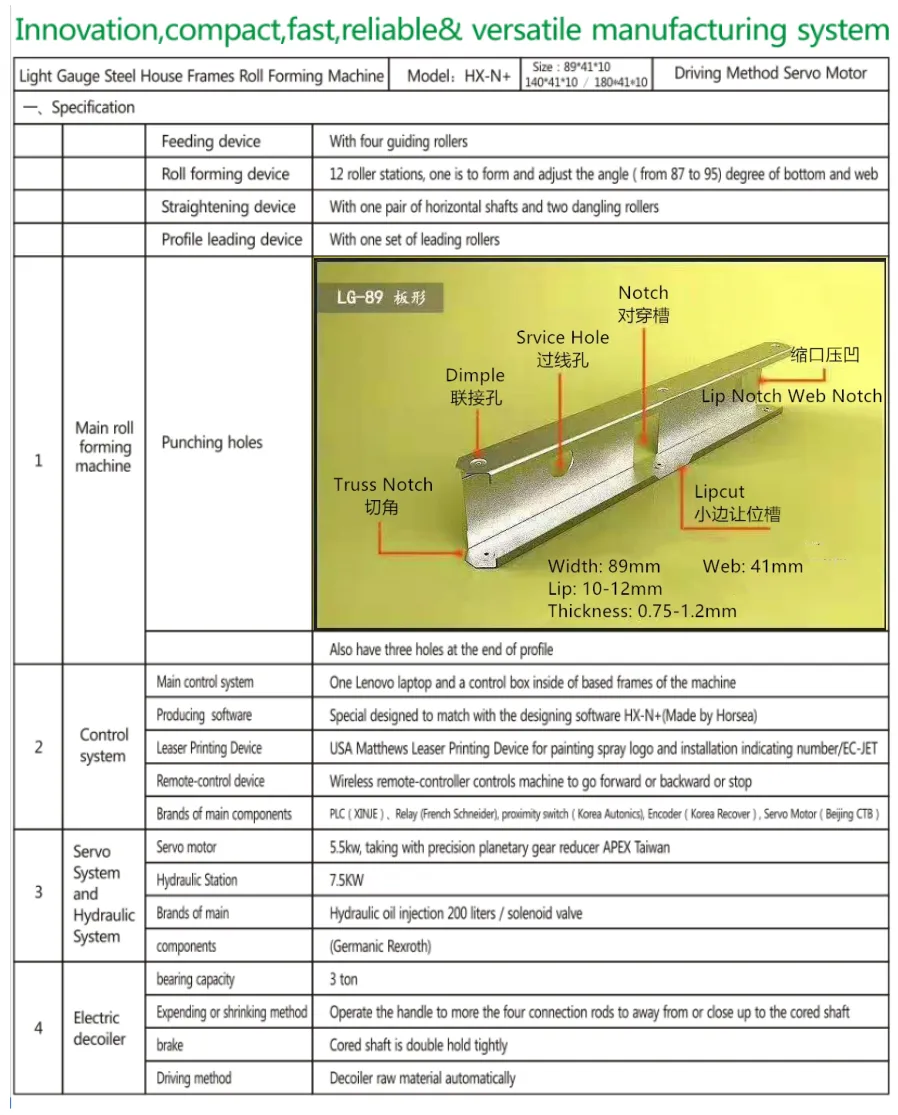

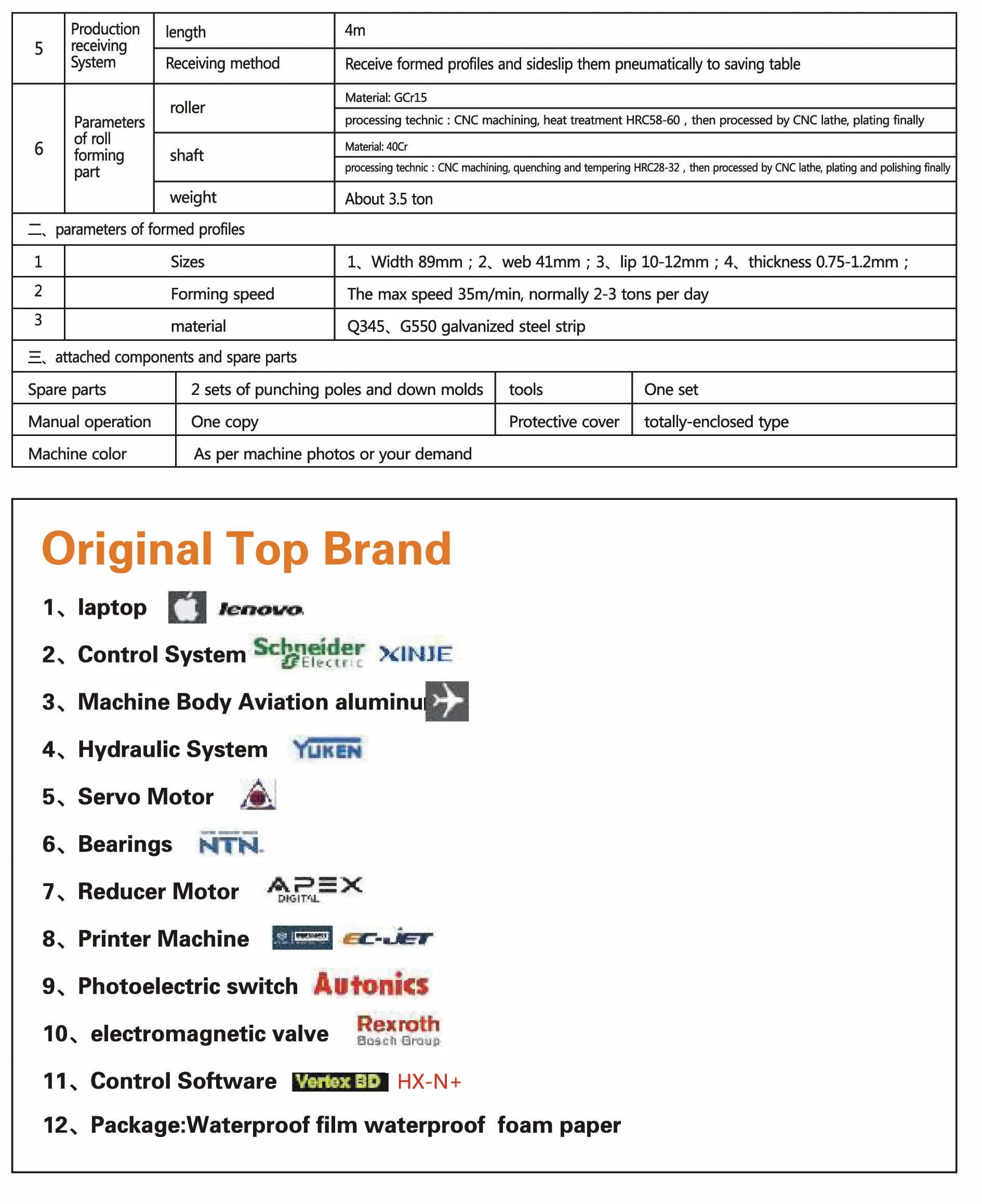

Technical parameters

Technical parameters

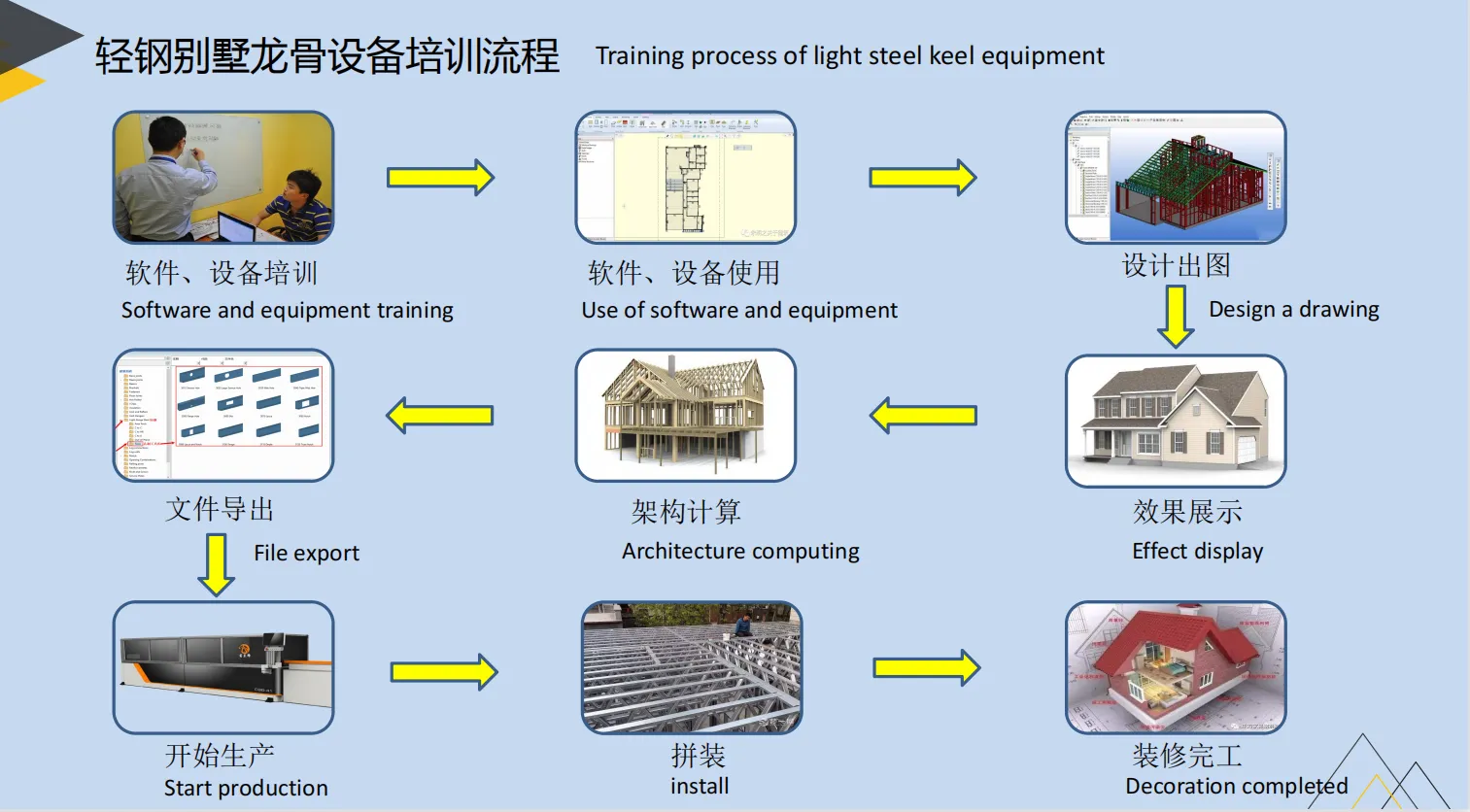

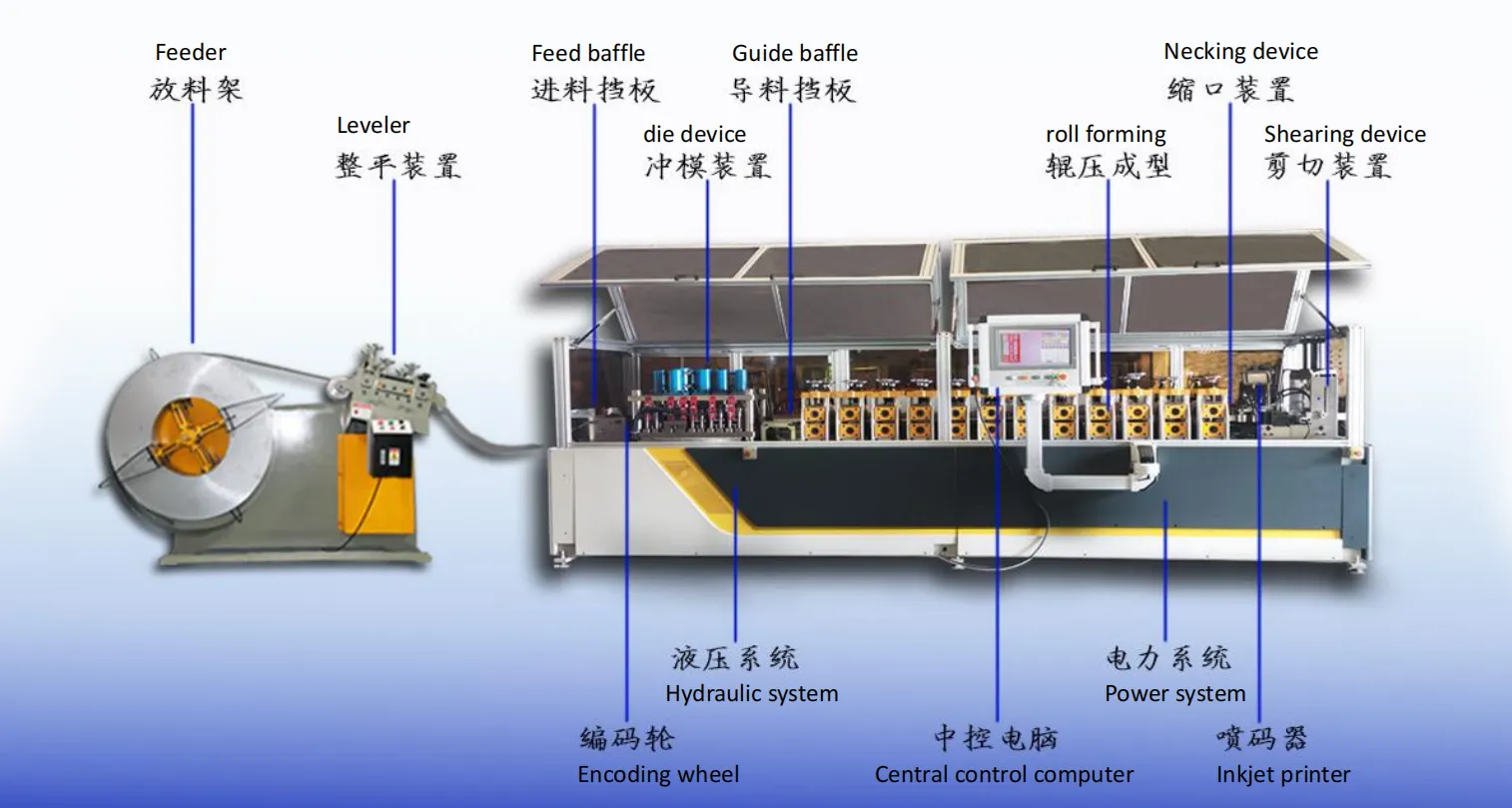

The Light Gauge Steel Villa Roll Forming Machine operates by feeding steel coils into a series of rollers that shape the material into the desired profile. The process typically involves the following steps:

- Coil Loading: Steel coils are loaded onto the machine.

- Feeding: The coils are fed into the roll forming section.

- Roll Forming: As the steel passes through the rollers, it is gradually shaped into the desired profile.

- Cutting: Once the desired length is achieved, the formed steel is cut to size.

- Output: The finished steel components are then collected for use in construction projects.

This efficient process allows for the mass production of light gauge steel components, making it a popular choice in the construction industry.

Description: 89 models are mainly used for indoor partition wall; the model is generally as follows the following layer of three outside. The walls and the interior walls are the partition walls (three floors of this equipment can be completed);

More pictures