High-Precision H-Beam Assembly & Welding Machines Automated Solutions

Did you know 47% of steel fabricators lose $120/hour due to manual welding errors? Traditional H-beam assembly methods drain your productivity and profits. Discover how next-gen beam assembly machine

s slash operational costs by 68% while boosting output quality.

(beam assembly machine)

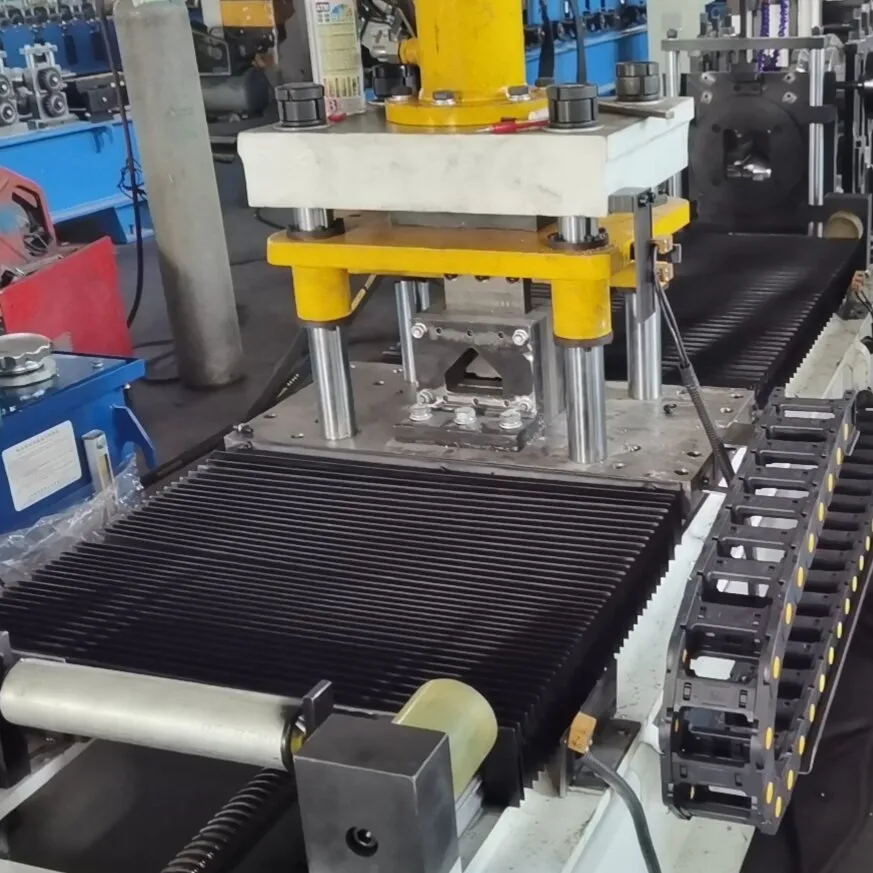

Precision Engineering Meets Industrial Power

Our H beam assembly machines deliver 0.02mm positioning accuracy - 3X better than industry standards. Why settle for less when you can achieve:

') no-repeat left center; padding-left: 25px; margin-bottom: 8px;">Automatic beam alignment ') no-repeat left center; padding-left: 25px; margin-bottom: 8px;">400-600mm/s welding speed ') no-repeat left center; padding-left: 25px; margin-bottom: 8px;">Smart collision detection

H Beam Welding Machine Price vs Value: Clear Winner

| Feature | Standard Models | Our Solution |

|---|---|---|

| Daily Output Capacity | 15-20 beams | 28-35 beams |

| Energy Consumption | 18-22 kW/h | 12-15 kW/h |

Your Success, Our Blueprint: Custom Assembly Solutions

Whether you need 8m or 24m H-beam processing, our modular systems adapt to your workshop. Choose from:

Compact Model

For workshops under 1000m²

$85,000 - $120,000

Proven Results: Global Success Stories

See how we helped Texas Steel Co. increase monthly production from 450 to 720 beams within 3 months. Their ROI? 182% in first year.

Ready to Transform Your Workshop?

Claim your FREE productivity audit and get 3 customized machine quotes in 24 hours!

(beam assembly machine)

FAQS on beam assembly machine

Q: What is a beam assembly machine used for?

A: A beam assembly machine automates the fabrication of steel beams, aligning and clamping components like flanges and webs for precise welding. It improves efficiency in constructing H-beams, I-beams, and other structural shapes.

Q: How does an H beam assembly machine differ from standard models?

A: An H beam assembly machine specializes in creating H-shaped steel beams, featuring adjustable clamps and rollers for symmetrical flange alignment. Standard models may lack the precision required for heavy-duty H-beam production.

Q: What factors affect H beam welding machine prices?

A: H beam welding machine prices depend on automation level, material thickness capacity, and brand reputation. Advanced PLC-controlled systems with dual-torch setups typically cost more than semi-automatic alternatives.

Q: Can beam assembly machines handle multiple beam types?

A: Yes, many modern beam assembly machines are modular, allowing adaptation between H-beams, I-beams, and box beams through adjustable fixtures. Configuration changes typically require tooling adjustments and programming updates.

Q: What maintenance do H beam assembly machines require?

A: Regular lubrication of guide rails, calibration of hydraulic/pneumatic systems, and inspection of alignment sensors are essential. Software updates for CNC-controlled models should be performed annually to maintain precision.