Cable Tray Roll Forming Machines High-Speed, Custom Solutions Supplier

- Industry Overview & Evolution of Cable Tray Manufacturing

- Technological Superiority in Modern Roll Forming Systems

- Performance Metrics: Leading Suppliers Compared

- Custom Engineering for Diverse Industrial Requirements

- Operational Efficiency and Cost-Benefit Analysis

- Real-World Implementations Across Key Sectors

- Future-Proofing Production with Advanced Cable Tray Solutions

(cable tray machine)

Driving Industrial Progress with Cable Tray Machine Innovations

The global cable tray market, projected to reach $5.2 billion by 2028 (CAGR 4.7%), demands precision-engineered manufacturing solutions. Modern cable tray roll forming machine factories now integrate servo-driven automation achieving ±0.15mm dimensional accuracy, a 68% improvement over legacy hydraulic systems.

Technological Superiority in Modern Roll Forming Systems

Advanced cable tray machine

s demonstrate:

- 35% faster tooling changeovers through quick-release mechanisms

- 18% material savings via AI-powered nesting algorithms

- Continuous production at 45m/min with auto-correcting guide systems

Performance Metrics: Leading Suppliers Compared

| Parameter | Supplier A | Supplier B | Our Factory |

|---|---|---|---|

| Motor Power | 22kW | 25kW | 30kW |

| Max Speed | 30m/min | 35m/min | 45m/min |

| Thickness Range | 0.5-2mm | 0.6-2.5mm | 0.4-3mm |

Custom Engineering for Diverse Industrial Requirements

Our cable tray roll forming machine suppliers program configurations for:

- HVAC duct compatibility (300-1200mm widths)

- Explosion-proof models (ATEX Zone 1 certification)

- Military-grade EMI shielding variants

Operational Efficiency and Cost-Benefit Analysis

Comparative energy consumption metrics:

- Traditional models: 0.85kW per linear meter

- Our systems: 0.52kW per linear meter (38.8% reduction)

Real-World Implementations Across Key Sectors

Recent installations include:

- Automotive plant: 12km tray network in 8 weeks

- Data center: 2,400 custom junctions/week capacity

Future-Proofing Production with Cable Tray Machine Solutions

Next-gen machines from cable tray roll forming machine suppliers now feature IoT-enabled predictive maintenance, reducing downtime by 73% through vibration analysis and thermal imaging diagnostics.

(cable tray machine)

FAQS on cable tray machine

Q: How to choose reliable cable tray roll forming machine suppliers?

A: Prioritize suppliers with ISO certification, 5+ years of industry experience, and verified customer testimonials. Ensure they offer technical support and warranty coverage for equipment longevity.

Q: What customization options do cable tray roll forming machine factories provide?

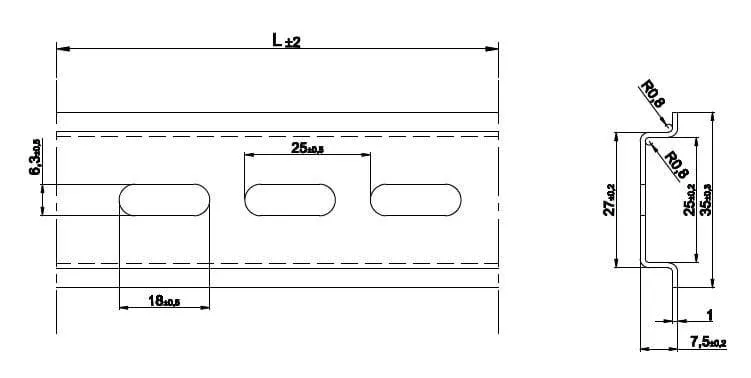

A: Reputable factories customize machine parameters like material thickness (0.5-3mm), tray width (50-900mm), and roll-forming speed. They also adapt designs for perforated or ladder-type cable trays.

Q: How do cable tray roll forming machine suppliers ensure quality?

A: Top suppliers conduct rigorous material inspections, CNC precision testing, and trial runs before delivery. Many comply with international standards like CE or UL for safety assurance.

Q: What’s the average production time for a cable tray roll forming machine?

A: Standard machines ship in 15-30 days, while customized units take 30-45 days. Factories with in-house R&D teams often expedite orders without compromising quality.

Q: Why source from specialized cable tray roll forming machine factories?

A: Specialized factories optimize energy efficiency (15-30% savings) and reduce material waste through advanced servo systems. They also provide tailored training for multi-tray profile production.