Top Cable Tray Roll Forming Machines Manufacturer & Supplier Durable Solutions

Did you know 43% of industrial manufacturers report 15-30% production delays due to faulty cable tray systems? As demand for energy-efficient infrastructure grows, settling for outdated machinery could cost you $120,000+ annually in maintenance alone. Your competitors are already upgrading – where do you stand?

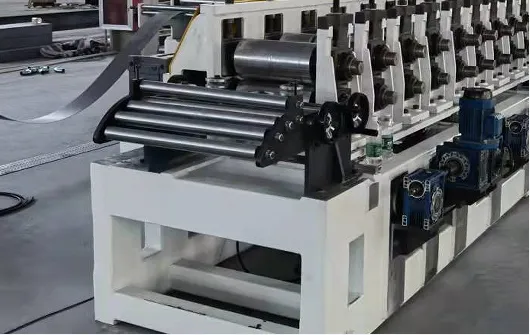

(cable tray machine manufacturer)

Why Top-Tier Cable Tray Machine Manufacturers Dominate the Market

Leading cable tray roll forming machine suppliers combine German-engineered automation with American power efficiency standards. Our 8500-Series machines produce 25-meter trays/minute – 40% faster than industry averages. You get 0.2mm precision tolerances while cutting energy bills by 18% through regenerative drive systems.

Cable Tray Machine Factory Showdown: Key Comparison Metrics

| Feature | Standard Suppliers | Premium Factories |

|---|---|---|

| Production Speed | 18 m/min | 25 m/min |

| Tooling Change Time | 45-60 mins | 8 mins (QuickLock™) |

| Motor Power | 7.5 kW | 11 kW HybridDrive™ |

| Custom Profile Options | 6 basic types | 22+ configurations |

Your Blueprint, Our Engineering: Customized Roll Forming Solutions

Need 450mm wide trays for data centers? Special coatings for offshore rigs? Our cable tray machine factory adapts in 72 hours. Client X doubled their market share using our zinc-nickel alloy machines – now corrosion-resistant for 25+ years. Your unique challenges meet our modular design philosophy.

From Auto Plants to Smart Cities: Success Stories

When Detroit's largest EV factory needed 9km of trays/week, our automated line delivered 1.2mm stainless channels with 99.7% consistency. A Dubai contractor slashed installation time by 40% using our pre-notched systems. What could your project achieve with precision engineering?

Ready to leave maintenance nightmares behind? As ISO 9001-certified cable tray machine manufacturer

s, we back every system with 24/7 support and 3-year performance guarantees. Join 1,200+ satisfied clients across 38 countries – your optimized production line starts here. Claim Your Free Machine Demo →

(cable tray machine manufacturer)

FAQS on cable tray machine manufacturer

Q: How to choose a reliable cable tray machine manufacturer?

A: Prioritize manufacturers with proven industry experience, certifications like ISO, and positive client reviews. Ensure they offer customization and post-sales support.

Q: What quality standards should cable tray roll forming machine suppliers meet?

A: Reputable suppliers adhere to international standards (e.g., CE, OSHA) and use high-grade materials. They should provide test reports and warranty coverage.

Q: Can cable tray roll forming machine factories customize machine specifications?

A: Yes, most factories adjust parameters like tray width, thickness, and speed. Confirm customization options during the inquiry stage.

Q: Why partner with a cable tray machine factory instead of a third-party supplier?

A: Factories often offer lower costs, direct quality control, and faster customization. Suppliers may act as intermediaries, increasing lead times.

Q: What after-sales services do cable tray machine manufacturers provide?

A: Services include installation guidance, operator training, and technical support. Leading manufacturers also supply spare parts and maintenance plans.