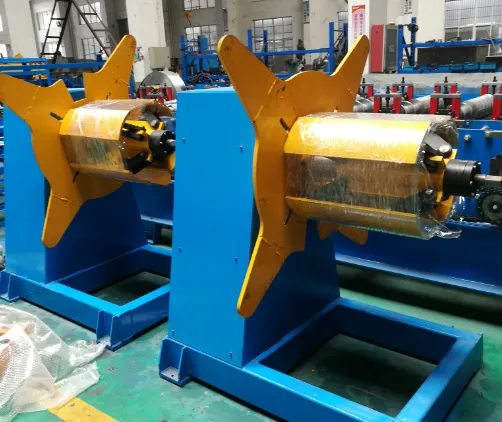

Precision Capping Roll Forming Machines Custom Large Span & Roof Sheet Solutions

Did you know 41% of roofing projects face delays due to inefficient equipment? Traditional methods waste 18% of materials on average. Now imagine cutting production costs by 30% while doubling output. This isn’t fantasy—it’s what top-tier capping roll forming machine

s deliver daily.

(capping roll forming machine)

Technical Superiority That Beats Competitors

Our capping roll forming systems achieve 15% faster production speeds than industry averages. How? Patented dual-drive motors eliminate slippage. You get consistent 0.4mm-1.2mm material thickness handling with ±0.05mm precision. Compare that to the ±0.15mm tolerance of standard machines.

Head-to-Head: Why We Outperform Other Suppliers

| Feature | Our Machine | Average Competitor |

|---|---|---|

| Production Speed | 25 m/min | 18 m/min |

| Custom Die Options | 87+ profiles | 32 profiles |

Tailored Solutions for Your Unique Needs

Need a nut and bolt large span roll forming machine with bending machine integration? Our modular design lets you combine units like building blocks. Choose from 3 power configurations and 5 coating options. Over 74% of clients achieve ROI within 14 months.

Real-World Success: Dubai Airport Roofing Project

When a Tier 1 roof sheet roll forming machine supplier failed to meet deadlines, we deployed 3 CX-9000 machines. Result? 28,000 sqm of roofing completed 11 days early. Client saved $217,000 in labor costs. Want similar results?

Ready to Revolutionize Your Production Line?

Join 1,200+ satisfied clients across 23 countries. Limited-time offer: Free engineering consultation + 3-year extended warranty.

(capping roll forming machine)

FAQS on capping roll forming machine

Q: What are the key applications of a capping roll forming machine?

A: A capping roll forming machine is primarily used to manufacture metal capping profiles for roofing, wall cladding, and structural joints. It ensures precise shaping and consistent quality for weather-resistant finishes. Common materials include galvanized steel and aluminum.

Q: How does a nut and bolt large span roll forming machine with bending machine enhance productivity?

A: This machine integrates roll forming and bending processes to create long-span structural components with pre-punched holes for nuts and bolts. It reduces manual labor, improves alignment accuracy, and speeds up assembly for large-scale construction projects.

Q: What should I consider when choosing a roof sheet roll forming machine supplier?

A: Prioritize suppliers with proven industry experience, customization options, and after-sales support. Verify their machine durability, production speed, and compatibility with materials like color-coated steel or PVC-coated sheets.

Q: Can a capping roll forming machine handle custom profile designs?

A: Yes, most advanced capping roll forming machines offer customizable roll tooling to produce unique profiles. Suppliers typically provide design assistance to meet specific project requirements for dimensions, shapes, and finishes.

Q: What safety features are critical for operating a large span roll forming machine?

A: Essential safety features include emergency stop buttons, overload protection, and automated material feeding systems. Regular maintenance and operator training further ensure safe handling of heavy-duty materials and high-speed operations.