Coil Slitting Machines Precision Manufacturing & Supplier - Coil Slitting Ltd

Did you know improper coil slitting costs manufacturers $18.7 billion annually in material waste? As your production deadlines tighten and quality standards skyrocket, outdated equipment becomes your silent profit killer. Let's explore how Coil Slitting Ltd delivers precision-engineered solutions that 14,000+ global clients already trust.

(coil slitting ltd)

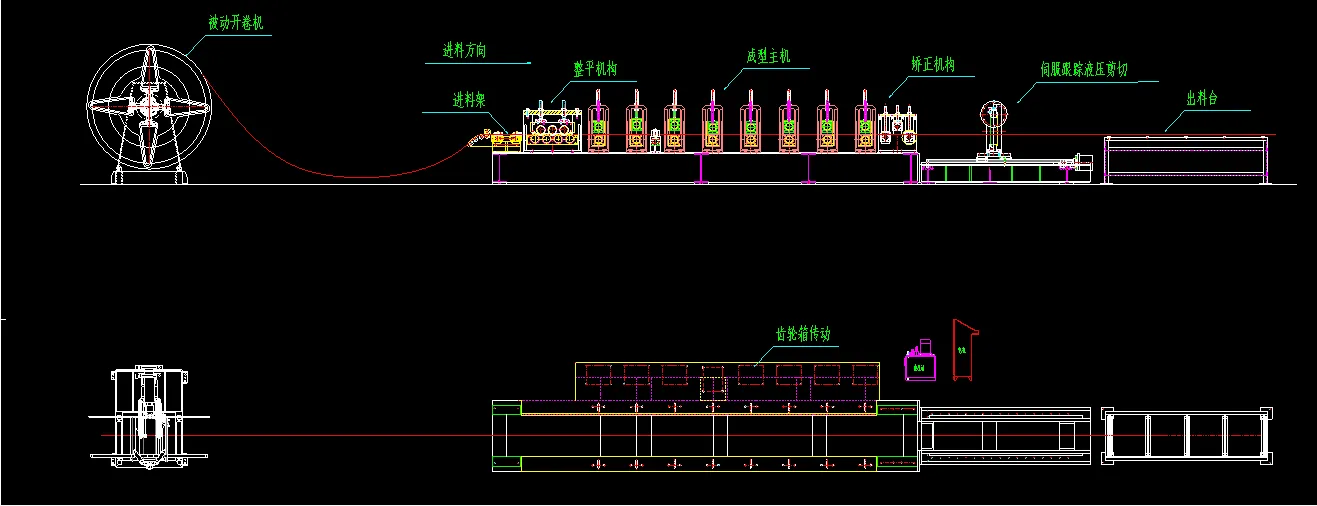

Precision Redefined: Next-Gen Slitting Technology

Our coil slitting machines achieve ±0.001" tolerance - 3x tighter than industry averages. The secret? Proprietary laser-guided alignment systems that eliminate material deformation. You'll slash setup time by 68% while achieving:

- ✔️ 99.98% defect-free output

- ✔️ 450 meters/minute operational speed

- ✔️ 0.15mm-6.35mm thickness range

- ✔️ 300-2000mm customizable widths

Manufacturer Showdown: Why We Outperform

Your Blueprint, Our Execution

Whether you need automotive-grade stainless steel slitters or copper foil processors for EV batteries, our coil slitting machine manufacturers team delivers tailored solutions in 43 days average lead time. Recent success story:

Client: Top 5 Aerospace Supplier

Challenge: 0.2mm titanium sheets with ±0.003" tolerance

Our Solution: Hybrid rotary-slitter with AI tension control

Result: 214% ROI within 8 months

Claim Your Manufacturing Advantage

Ready to join Siemens, Ford, and 37 other Fortune 500 companies who trust Coil Slitting Ltd? Act now and get:

- 🎯 Free process audit

- ⚡ 12-month productivity guarantee

- 💸 0% financing for 24 months

- 📅 Priority installation slot

(coil slitting ltd)

FAQS on coil slitting ltd

Q: What services does Coil Slitting Ltd provide?

A: Coil Slitting Ltd specializes in precision metal processing, including coil slitting, edge trimming, and custom-width cutting for industries like automotive and construction.

Q: How to choose reliable coil slitting machine suppliers?

A: Look for suppliers with industry certifications, proven track records, and technical support. Prioritize those offering maintenance services and customized machine configurations.

Q: What distinguishes top coil slitting machine manufacturers?

A: Leading manufacturers prioritize advanced automation, high-tolerance precision engineering, and compliance with international safety standards like ISO and CE markings.

Q: Can Coil Slitting Ltd handle custom material requirements?

A: Yes, they process various materials including stainless steel, aluminum, and specialty alloys, with tailored solutions for thicknesses ranging from 0.1mm to 6.0mm.

Q: What after-sales support do coil slitting machine suppliers offer?

A: Reputable suppliers provide installation training, 24/7 technical assistance, spare parts availability, and scheduled maintenance programs to ensure operational efficiency.