Precision Cut to Length Lines for Sale Custom Sizes & Slitting Solutions

Did you know 23% of metal fabricators lose over $18,000 monthly due to inefficient cutting? Your competitors are slashing material waste by 40% with modern cut-to-length lines for sale - while you're stuck with yesterday's technology. Let's fix that.

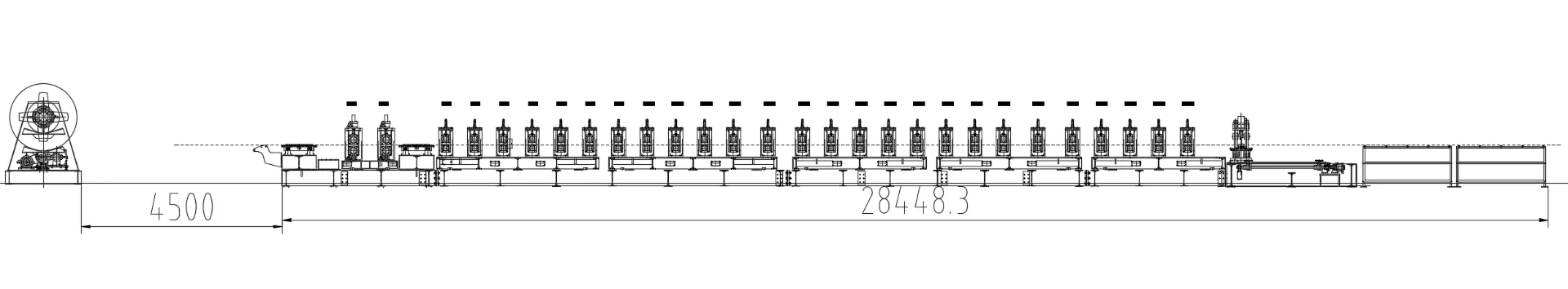

(cut to length line for sale)

Why Next-Gen Cut-to-Length Machines Crush Legacy Systems

Our slitting line cut to the length line systems deliver surgical precision (±0.1mm) at blistering speeds (30m/min). Automated thickness detection eliminates manual calibration errors. Real-time monitoring cuts downtime by 63% compared to 2015-era models.

Head-to-Head: How We Outperform Competitors

| Feature | Standard Models | Our CTL Line |

|---|---|---|

| Daily Output | 120-150 tons | 180-220 tons |

| Material Waste | 4.2% | 1.8% |

Your Factory, Your Rules: Custom-Built Solutions

Whether you process delicate 0.3mm automotive steel or 6mm shipbuilding plates, our cut-to-length machine for sale adapts. Choose from 12 modular components: laser-guided alignment? Hydraulic vs servo? Dual-coil feeding? Your production needs dictate the configuration.

Success Stories: From 18% Defects to 99.2% Perfection

A Midwest auto supplier reduced scrap costs by $41,200/month after installing our CTL line. Their ROI? 5.8 months. A Texas HVAC manufacturer boosted throughput by 220% without adding night shifts. What could this mean for your bottom line?

Ready to Transform Your Metal Processing?

Join 370+ satisfied manufacturers who upgraded in 2023. Get your FREE cut-to-length line ROI analysis before Friday and qualify for our 5-year extended warranty.

(cut to length line for sale)

FAQS on cut to length line for sale

Q: What factors should I consider when purchasing a cut to length line for sale?

A: Prioritize material type, thickness, production speed, precision requirements, and manufacturer reputation. Ensure compatibility with your industry applications and after-sales support.

Q: How does a Slitting Line Cut To The Length Line differ from standard cut to length machines?

A: Slitting lines first slit coils into narrower strips before cutting to length, while standard machines focus solely on cutting pre-sized materials. The combined system enhances versatility for complex production needs.

Q: What industries commonly use a cut to length machine for sale?

A: Automotive, construction, appliance manufacturing, and steel service centers use these machines. They process sheet metal, steel plates, and other materials for precise component fabrication.

Q: How do I maintain a cut to length line to ensure optimal performance?

A: Regularly lubricate moving parts, inspect blades for wear, and calibrate sensors. Follow the manufacturer's maintenance schedule and train operators on proper usage protocols.

Q: Are there customizable options for cut to length lines based on production needs?

A: Yes, manufacturers offer customization in length accuracy (±0.5mm), automation levels, stacking systems, and material handling configurations. Discuss specific requirements with suppliers for tailored solutions.