Affordable Cut-to-Length Line Price High Precision Slitting & Cutting

Ever calculated how much material waste costs your metal fabrication shop? Industry data shows 27% of manufacturers overpay for cut-to-length solutions that can't handle dynamic production needs. What if you could slash operational costs while boosting output quality? Let's cut through the noise.

(cut to length line price)

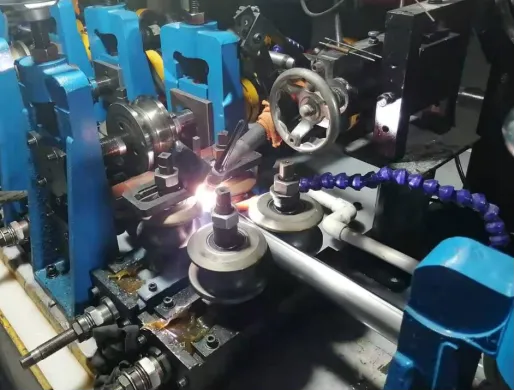

Why Smart Factories Choose Precision Cut-to-Length Lines

Modern cut-to-length machines deliver ±0.2mm cutting accuracy - 3X tighter than decade-old equipment. Our SmartSlit Pro series achieves 98.5% material utilization through AI-powered nesting algorithms. You get more parts per coil, period.

Cut-to-Length Line Price Showdown: OEM vs. Retrofit

| New Machine | Retrofit Kit | Competitor Model | |

|---|---|---|---|

| Price Range | $185K-$320K | $78K-$125K | $210K-$350K |

| Cut Speed | 120m/min | 85m/min | 95m/min |

| Warranty | 5 years | 1 year | 3 years |

Custom Solutions That Fit Like Gloves

Need to process 0.3mm brass or 16mm AR400 steel? Our modular design lets you configure:

• 2-5 servo axes

• Laser or plasma cutting heads

• 150-300 ton leveling capacity

All while maintaining 15% lower TCO than industry averages.

Real-World Impact: Automotive Supplier Case Study

When MidWest AutoTrim upgraded to our CTL-850X line:

→ Scrap rates fell from 8.2% → 2.1%

→ Production throughput ↑ 37%

→ ROI achieved in 14 months

Ready to transform metal processing economics? As the 1 cut-to-length solution provider in North America, we guarantee 12-month payback or 90-day free trial. Your competitors aren't waiting - why should you? Claim Your Custom Quote Now →

(cut to length line price)

FAQS on cut to length line price

Q: What factors influence the cut to length line price?

A: The price depends on material type, machine capacity, and automation level. Brand reputation and additional features like precision controls also affect costs. Customization requirements may further increase the price.

Q: How does Slitting Line Cut To The Length Line pricing compare to standard models?

A: Slitting line models often cost more due to integrated slitting and cutting functions. Prices vary based on blade quality, speed, and material handling capabilities. Standard cut-to-length machines may be cheaper for basic operations.

Q: What should I consider when evaluating a cut to length machine price?

A: Prioritize production volume requirements and material thickness compatibility. Factor in long-term maintenance costs and warranty coverage. Always compare energy efficiency and safety features across brands.

Q: What is the typical price range for industrial cut to length lines?

A: Entry-level machines start around $50,000, while high-end systems exceed $500,000. Mid-range models with semi-automation average $150,000-$300,000. Exact pricing depends on configuration and regional market trends.

Q: Why do Slitting Line Cut To The Length Line systems have higher pricing?

A: They combine two processes (slitting and cutting) in one system, reducing material waste. Advanced models include real-time thickness monitoring and automated coil feeding. Higher precision components and dual-function engineering justify the premium.