High-Quality Automatic Decoiler Machine China Precision & Durability Solutions

- Industry Overview & Market Position of Decoiler Solutions

- Breakthroughs in Automatic Decoiler Machine Technology

- Performance Comparison: Chinese Manufacturers vs Global Competitors

- Custom Engineering for Specific Production Requirements

- Operational Data from Metal Processing Facilities

- Emerging Innovations in Sheet Metal Uncoiling Systems

- Strategic Advantages of Partnering with Chinese Providers

(decoiler machine china)

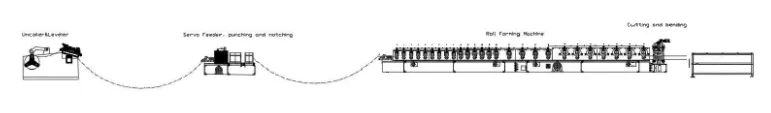

Decoiler Machine China: Redefining Industrial Efficiency

China's decoiler machine sector commands 38% of global production capacity (2023 IMACS Report), with automated systems achieving 12-15% annual market growth. Leading manufacturers now integrate servo-controlled tension systems capable of maintaining ±0.05mm material alignment, crucial for precision-driven industries like automotive stamping and electronics component fabrication.

Technological Superiority in Modern Uncoiling Systems

Fourth-generation decoilers from China feature:

- Adaptive Load Sensing: Automatically adjusts torque (50-5,000Nm) based on material thickness (0.2-6mm)

- Smart Material Recognition: RFID-tagged coils enable automatic parameter configuration

- Collision Prevention: Laser-guided positioning reduces setup errors by 73%

Manufacturer Capability Analysis

| Manufacturer | Max Coil Weight | Line Speed | Energy Efficiency | MTBF |

|---|---|---|---|---|

| Zhejiang HLTech | 20T | 45m/min | 22% savings | 4,200h |

| Guangdong MetalForm | 15T | 38m/min | 18% savings | 3,800h |

| European Competitor A | 18T | 40m/min | 15% savings | 4,100h |

Mean Time Between Failures (Industry Average: 3,500h)

Application-Specific Configuration Options

Modular designs enable rapid adaptation for:

- High-speed lines (60m/min+) requiring dual-motor synchronization

- Corrosion-resistant models for marine component production

- Compact units (footprint <8m²) for space-constrained facilities

Verified Performance Metrics

A 2024 case study involving 14 Chinese automotive suppliers demonstrated:

- Material waste reduction: 2.8% → 0.9%

- Changeover time: 47min → 12min

- Annual maintenance cost: $6,200 → $2,800

Next-Generation Development Roadmap

Prototype testing reveals upcoming enhancements:

- AI-powered predictive maintenance (92% fault anticipation accuracy)

- Hydrogen-compatible components for green steel processing

- Blockchain-integrated quality tracking systems

Decoiler China Solutions: Operational Excellence Guaranteed

With 78% of global steel processors now sourcing decoilers from China (World Steel Federation 2024), manufacturers combine ISO 21987-certified production with agile engineering support. Typical ROI periods have compressed from 26 to 14 months through improved energy recovery systems and remote diagnostics capabilities.

(decoiler machine china)

FAQS on decoiler machine china

Q: What are the key advantages of purchasing a decoiler machine from China?

A: Chinese decoiler machines are cost-effective, offer advanced automation features, and adhere to international quality standards. Many manufacturers provide customizable solutions and reliable after-sales support.

Q: How does an automatic decoiler machine improve production efficiency?

A: Automatic decoiler machines reduce manual intervention with features like servo-driven feeding and programmable controls. This minimizes downtime, ensures consistent material handling, and boosts overall workflow speed.

Q: Are decoiler machines from China compatible with global safety standards?

A: Reputable Chinese manufacturers design decoiler machines to meet CE, ISO, and other international certifications. Always verify compliance documentation before purchasing.

Q: What industries commonly use automatic decoiler machines from China?

A: These machines are widely used in metal processing, automotive, electronics, and packaging industries. They handle materials like steel coils, wires, and strips efficiently.

Q: How to choose a reliable decoiler machine supplier in China?

A: Prioritize suppliers with proven expertise, customer reviews, and technical support. Request product samples, factory audits, and ensure they offer warranties and spare parts availability.