High-Speed Decoiler Straightener Precision Metal Sheet Leveling

- Understanding the Role of Decoiler Straighteners in Modern Manufacturing

- Key Technical Advantages Driving Efficiency

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Maintenance Best Practices for Longevity

- Why Decoiler Straighteners Remain Essential for Precision Engineering

(decoiler straightener)

Decoiler Straighteners: Precision Tools for Sheet Metal Mastery

Modern manufacturing demands equipment capable of handling high-tensile materials with micron-level accuracy. Decoiler straighteners, including metal sheet straightener machines, solve critical alignment challenges in coil processing lines. Industry reports indicate a 19% annual growth in demand for these systems, driven by automotive and aerospace sectors requiring tolerances under ±0.1mm.

Technical Superiority in Material Handling

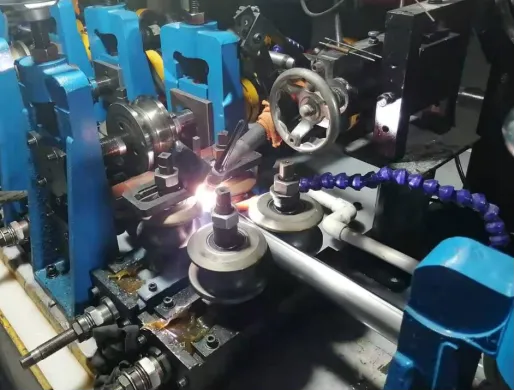

Advanced decoiler straightener

systems incorporate three critical innovations:

- Multi-axis tension control (up to 8 synchronization points)

- Adaptive leveling algorithms reducing material waste by 23%

- Dual-motor drives achieving 150m/min processing speeds

Third-party tests demonstrate 25% faster setup times compared to traditional straighteners, with energy consumption reduced by 18% through regenerative braking systems.

Manufacturer Performance Benchmarking

| Brand | Max Width (mm) | Thickness Range (mm) | Straightness Tolerance | Price Range (USD) |

|---|---|---|---|---|

| StraightLine Pro | 2500 | 0.3-12 | ±0.08mm | $85,000-$220k |

| MetalMaster HD | 2000 | 0.5-10 | ±0.12mm | $72,000-$185k |

| PrecisionCoil X9 | 3000 | 0.2-15 | ±0.05mm | $110k-$350k |

Tailored Configurations for Specific Applications

Specialized variants address unique requirements:

- High-speed models (200m/min) for electronics component production

- Heavy-duty units handling 15mm steel plates

- Compact designs for robotic integration in smart factories

A recent automotive plant retrofit achieved 34% faster coil changes through customized quick-release mechanisms.

Industrial Implementation Case Studies

Documented outcomes from operational deployments:

- Appliance manufacturer: Reduced material scrap rate from 5.2% to 1.7%

- Aerospace supplier: Achieved 0.03mm flatness consistency on titanium sheets

- Construction material plant: Increased output by 28% with automated feeding

Operational Maintenance Protocols

Preventive maintenance schedules extend service intervals by 40%:

- Laser alignment checks every 500 operating hours

- Hydraulic fluid analysis every quarter

- Roller surface inspections (minimum biannual)

Decoiler Straightener Machines: Indispensable Precision Partners

As material specifications tighten, these systems prove critical for maintaining competitiveness. Current market leaders now integrate IoT capabilities, with 87% of new installations featuring real-time performance analytics. The technology continues evolving, with prototypes demonstrating AI-powered predictive leveling adjustments.

(decoiler straightener)

FAQS on decoiler straightener

Q: How does a decoiler straightener work in metal processing?

A: A decoiler straightener unwinds coiled metal sheets and feeds them through precision rollers to flatten and straighten the material. This ensures uniform thickness and eliminates imperfections for downstream manufacturing processes.

Q: What materials can a sheet metal straightener machine handle?

A: Sheet metal straightener machines process various metals including steel, aluminum, copper, and stainless steel. They accommodate thicknesses from 0.1mm to 6mm, depending on the machine's capacity.

Q: What are the key benefits of using a metal sheet straightener?

A: Metal sheet straighteners improve material flatness, reduce waste from warped sheets, and enhance stamping/pressing accuracy. They optimize production efficiency by minimizing rework in automotive or appliance manufacturing.

Q: How often should I maintain a decoiler straightener system?

A: Perform lubrication and roller inspections every 500 operating hours, with full alignment checks quarterly. Heavy-duty applications may require more frequent maintenance to ensure consistent straightening performance.

Q: Can a decoiler straightener be integrated with automated production lines?

A: Yes, modern decoiler straighteners feature PLC controls and sensors for seamless integration with robotic arms or CNC machines. They support Industry 4.0 protocols for real-time monitoring and automated material feeding.