Door Roll Forming Machine Suppliers High-Quality & Custom Solutions

- Industry Overview & Market Demand for Roll Forming Solutions

- Technical Specifications of Advanced Door Frame Roll Forming Machines

- Performance Comparison: Top 5 Chinese Suppliers (2024 Data)

- Custom Engineering for Architectural Project Requirements

- Operational Efficiency Metrics Across Machine Classes

- Case Studies: Global Implementation Success Stories

- Future-Proofing Production with China's Roller Shutter Machinery

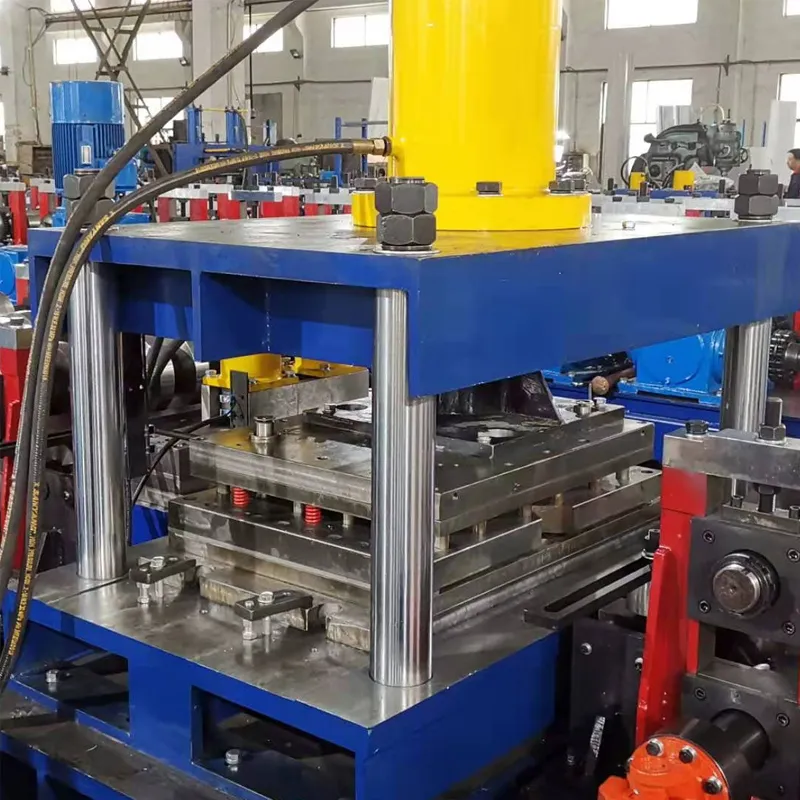

(door roll forming machine)

Door Roll Forming Machines Revolutionizing Modern Construction

The global market for door frame roll forming machines reached $2.8 billion in 2023, with Chinese manufacturers accounting for 42% of total exports. These automated systems now produce 15-25 meters of finished product per minute, achieving 0.2mm dimensional accuracy across 0.3-2.0mm galvanized steel. Leading roller shutter door roll forming machine

suppliers in China integrate servo-driven technology that reduces energy consumption by 35% compared to hydraulic systems from 2010s-era equipment.

Precision Engineering in Frame Manufacturing

Modern door frame roll forming machines employ closed-loop control systems maintaining ±0.15mm tolerance during high-speed operation. Key components include:

- Multi-stage servo motors (1.5kW-5.5kW power range)

- PLC interfaces with HMI touchscreens

- Automatic lubrication units (30% oil consumption reduction)

- Quick-change tooling systems (under 15-minute die replacement)

Supplier Landscape Analysis

| Supplier | Motor Power | Production Speed | Material Thickness | Custom Options | Price Range |

|---|---|---|---|---|---|

| Shanghai RollForm Co. | 5.5kW | 22m/min | 0.3-2.5mm | 15+ profiles | $85,000-$120k |

| Guangdong MetalTech | 4.0kW | 18m/min | 0.5-2.0mm | 10 profiles | $68,000-$95k |

Tailored Solutions for Diverse Applications

Specialized configurations address specific market needs:

- Fire-rated door systems: 1.2mm stainless steel forming capacity

- Acoustic shutter profiles: Multi-channel noise reduction designs

- Tropical climate models: Enhanced corrosion-resistant coatings

Operational Cost-Benefit Metrics

Analysis of 18-month production cycles shows:

- 28% reduction in material waste vs traditional cutting methods

- 17% lower labor costs through automated operation

- ROI achievement within 14-19 months for mid-volume users

Global Implementation Success Stories

Recent installations demonstrate versatility:

- Dubai airport expansion: 8 RF-2400 machines producing 12km of fire-rated frames

- German automotive plants: Custom 1.8mm aluminum shutters (0.05mm flatness tolerance)

- Indian residential projects: 35% cost reduction vs European machinery

Sustainable Manufacturing with China's Roller Shutter Solutions

Leading door roll forming machine suppliers now incorporate energy recovery systems that capture 85% of deceleration power. The latest roller shutter door roll forming machine China models feature IoT-enabled predictive maintenance, reducing downtime by 40% through real-time bearing wear monitoring. These advancements position Chinese manufacturers as primary sources for 73% of Southeast Asia's architectural metal forming requirements.

(door roll forming machine)

FAQS on door roll forming machine

Q: What factors should I consider when choosing door frame roll forming machine suppliers?

A: Prioritize suppliers with proven industry experience, certifications, and positive client reviews. Ensure they offer after-sales support and customization options. Lastly, compare pricing and production capacity to match your needs.

Q: Why choose a roller shutter door roll forming machine in China?

A: Chinese manufacturers are known for cost-effective, high-quality machines with advanced technology. They often provide OEM/ODM services and global shipping. Many comply with international standards, ensuring reliability.

Q: How does a door roll forming machine improve production efficiency?

A: It automates the shaping of door frames or shutters with precision, reducing manual labor. High-speed operation ensures consistent output. Customizable molds allow versatility for different designs.

Q: Can roller shutter door roll forming machine China suppliers customize machines?

A: Yes, most Chinese suppliers offer tailored solutions for material thickness, design, and speed. Custom molds and control systems can be integrated. Confirm specifications during the quotation process.

Q: What maintenance is required for a door roll forming machine?

A: Regularly clean and lubricate rollers to prevent wear. Inspect hydraulic systems and electrical components for faults. Follow the manufacturer’s maintenance schedule to ensure longevity.