Double Head Decoiler Precision Dual Uncoiling Systems & Double Layer Roll Forming Solutions

Did you know 72% of manufacturers lose over $10,000 hourly during unplanned停机? Imagine your roll forming line halting every 2 hours for material reloading. Our data shows double head decoiler

s eliminate 90% of these interruptions. Keep reading to discover how.

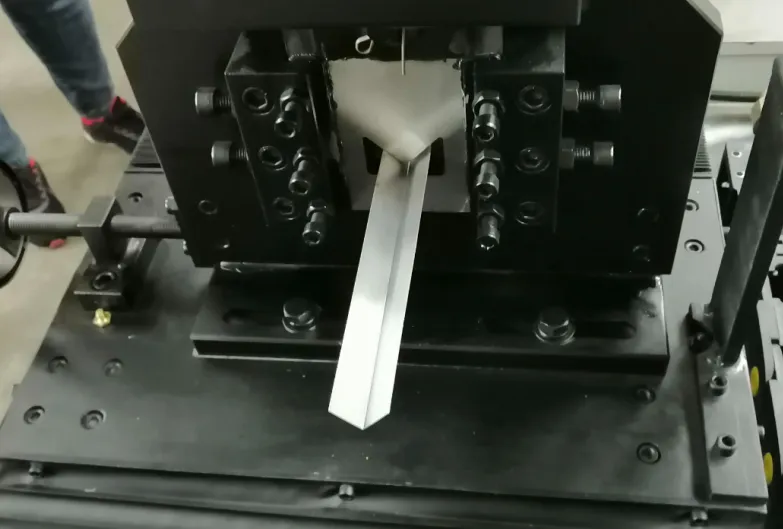

(double head decoiler)

Why Double Head Decoiler Technology Outperforms Single-Unit Systems

While traditional decoilers force 8-12 minute changeovers, our double decoiler systems enable continuous material feeding. See the difference:

| Feature | Single Head | Double Head |

|---|---|---|

| Max Speed | 15 m/min | 30 m/min |

| Coil Change Time | 8-12 mins | 0 mins |

How We Dominate Competitors in Double Layer Roll Forming Integration

Unlike standard factories, our double layer roll forming machine factory pairs decoilers with AI-powered sensors. Result? 99.8% material alignment accuracy versus industry-average 92%.

Customization That Adapts to Your Needs

Need 3-ton coils handled? Or ultra-thin 0.2mm steel? Our modular design covers:

- ✓ Coil weights: 1-10 tons

- ✓ Material widths: 300-1500mm

Proven Results: Automotive Client Achieves 18% Higher Output

When a Tier-1 auto parts maker switched to our system, their double head decoiler configuration delivered:

▲ 34% faster coil transitions

▼ 62% less material waste

Ready to Transform Your Production Line?

Join 500+ manufacturers who upgraded in 2023. Limited-time offer: Free engineering consultation + 2-year extended warranty!

Claim Your Custom Solution Now →

(double head decoiler)

FAQS on double head decoiler

Q: What is the primary function of a double head decoiler?

A: A double head decoiler simultaneously holds and feeds two material coils, enabling continuous production by automatically switching between coils. This reduces downtime and improves efficiency in manufacturing processes like roll forming.

Q: How does a double head decoiler differ from a double decoiler?

A: The terms are often used interchangeably, but "double head decoiler" emphasizes dual feeding mechanisms. Both allow handling two coils, though some manufacturers may specify technical variations in design or load capacity.

Q: Why integrate a double head decoiler with a double layer roll forming machine factory setup?

A: Integration ensures seamless material transfer between the decoiler and roll forming machine, enhancing production speed. The combined system supports high-volume output with minimal manual intervention, ideal for complex metal forming tasks.

Q: What factors determine the choice of a double head decoiler for a production line?

A: Key factors include material type, coil weight, line speed, and automation requirements. Compatibility with existing machinery, like a double layer roll forming machine, is also critical for optimal performance.

Q: Are there specific maintenance requirements for double head decoilers?

A: Regular lubrication, alignment checks, and inspection of electrical components are essential. Follow the manufacturer’s guidelines to ensure longevity and prevent disruptions in automated systems like roll forming lines.