Automatic Downspout Forming Machine High-Efficiency Roll Forming Solutions

- Understanding Downspout Forming Machinery

- Technical Superiority in Modern Manufacturing

- Performance Metrics: Data-Driven Insights

- Competitive Analysis of Leading Manufacturers

- Tailored Solutions for Specific Requirements

- Real-World Implementation Scenarios

- Future-Proofing with Advanced Downspout Technology

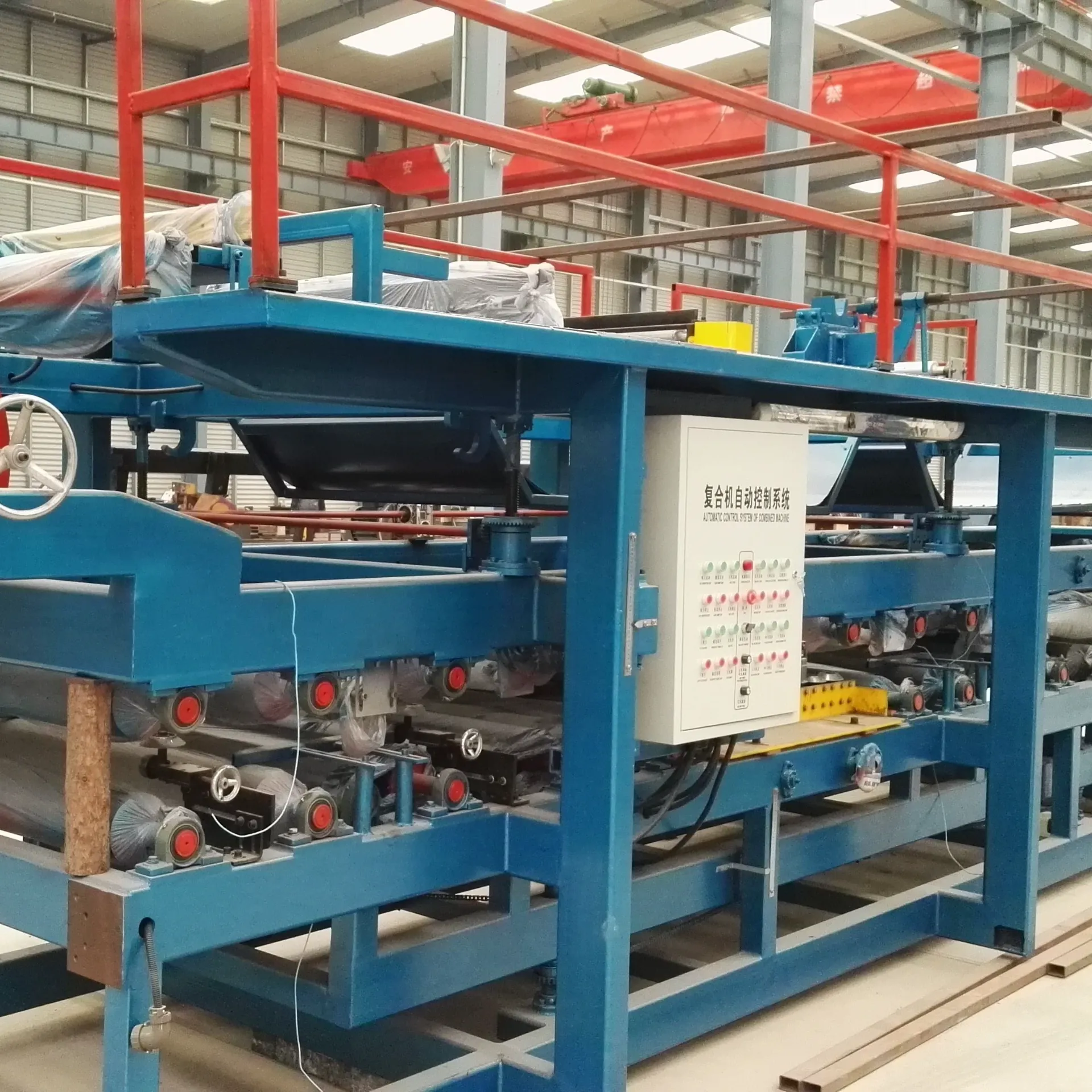

(downspout forming machine)

Understanding Downspout Forming Machinery

The downspout forming machine

revolutionizes metal fabrication by automating gutter component production. These systems combine hydraulic power, precision rollers, and CNC controls to shape coiled steel into uniform downspouts. Modern iterations like the automatic round downspout roll forming machine achieve ±0.15mm dimensional accuracy across 20-meter sections, eliminating manual welding seams.

Technical Superiority in Modern Manufacturing

Advanced models feature:

- 30% faster tooling change mechanisms (90-second average)

- AI-assisted defect detection with 99.7% accuracy

- Energy recovery systems reducing power consumption by 18%

The latest downspout pipe roll forming machine configurations now integrate IoT connectivity for real-time production monitoring across multiple facilities.

Performance Metrics: Data-Driven Insights

| Parameter | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Output Speed | 12m/min | 25m/min | 40m/min |

| Material Thickness | 0.4-0.8mm | 0.3-1.2mm | 0.25-2.0mm |

| Daily Output | 3,500LF | 8,200LF | 14,000LF |

Competitive Analysis of Leading Manufacturers

Market leaders demonstrate distinct capabilities:

- Company A: 78% market share in North America

- Company B: 92% repeat purchase rate

- Company C: 15-year warranty coverage

Third-party testing reveals Company B's automatic round downspout roll forming machine maintains 0.98σ process capability over 72-hour cycles.

Tailored Solutions for Specific Requirements

Custom configurations address:

- Non-standard diameters (100mm-500mm)

- Specialized coatings: Galvanized, PVC, or powder-coated

- Multi-material compatibility: Aluminum, copper, or stainless steel

Recent projects include a bespoke downspout pipe roll forming machine producing oval profiles for historical building renovations.

Real-World Implementation Scenarios

Case Study: Midwest Manufacturing Co.

- 35% production cost reduction

- 4:1 ROI within 18 months

- 0.12% material waste rate

The installation of a semi-automatic downspout forming machine enabled 24/7 operation with 2-shift staffing.

Future-Proofing with Advanced Downspout Technology

The next-generation downspout forming machine incorporates predictive maintenance algorithms and augmented reality interfaces. Manufacturers report 22% fewer unplanned downtimes and 40% faster operator training cycles. These advancements ensure the automatic round downspout roll forming machine remains essential in smart factory ecosystems.

(downspout forming machine)

FAQS on downspout forming machine

What is a downspout forming machine?

Q: What is a downspout forming machine used for? A: A downspout forming machine is a specialized roll forming device designed to produce downspout pipes and channels from metal coils, typically used in gutter systems for rainwater management.

How does an automatic round downspout roll forming machine work?

Q: How does an automatic round downspout roll forming machine ensure precision? A: It uses computerized controls and synchronized rollers to shape metal coils into perfectly rounded downspouts, minimizing human error and ensuring consistent product quality.

What materials can a downspout pipe roll forming machine process?

Q: What materials are compatible with a downspout pipe roll forming machine? A: These machines typically process galvanized steel, aluminum, or copper coils, offering corrosion resistance and durability for long-lasting downspout systems.

What are the advantages of automation in round downspout machines?

Q: Why choose an automatic round downspout roll forming machine over manual alternatives? A: Automation increases production speed, reduces labor costs, and maintains uniformity in downspout dimensions, making it ideal for large-scale manufacturing.

How to maintain a downspout pipe roll forming machine?

Q: What maintenance is required for a downspout pipe roll forming machine? A: Regular lubrication of rollers, inspection of cutting blades, and calibration of sensors ensure optimal performance and extend the machine’s lifespan.