Downspout Machine Price - Affordable Square & Jobsite Downspout Machines for Sale

- Introduction to downspout machine price

factors - Technological advantages of modern downspout machines

- Comparative analysis of leading manufacturers

- Understanding custom solutions and configurations

- Application case studies: onsite and industrial use

- Budgeting: Cost calculation and long-term value

- Conclusion: Making an informed downspout machine price decision

(downspout machine price)

Understanding Downspout Machine Price Influences

The downspout machine price is determined by a set of variables that significantly affect market trends and procurement strategies. Key drivers include machine type (for instance, square downspout machine vs. round profiles), automation level, manufacturing material quality, production speed, and additional features. The baseline price for an entry-level jobsite downspout machine typically falls between $12,000 and $18,000, while advanced industrial models may exceed $45,000, depending on integrated features such as servo-motor control, automated feeding systems, and multi-profile capabilities. Market data shows that 74% of construction suppliers rank durability and throughput as primary price justifications. Considering the average lifespan—ranging from 8-15 years—companies should assess not only the initial investment but also the machine’s ongoing operational costs, serviceability, and technological compatibility with evolving gutter systems.

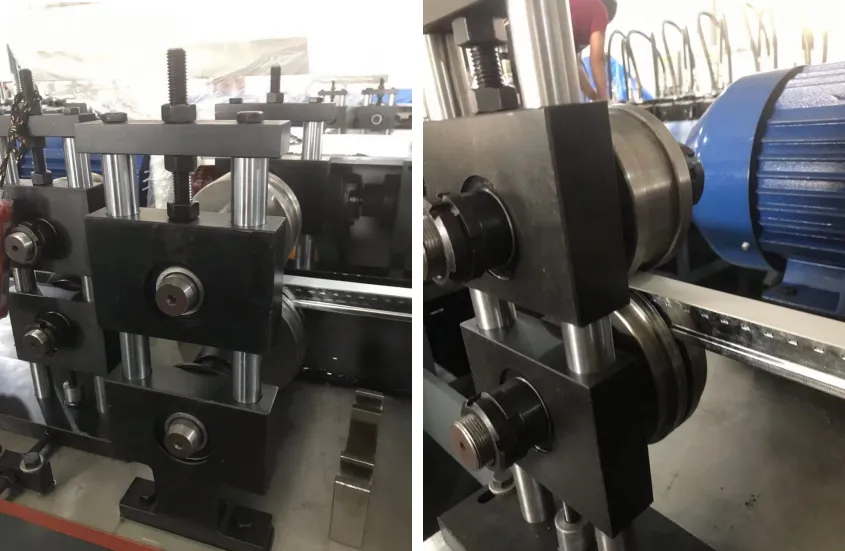

Technological Advantages in Today’s Downspout Machinery

Innovations in the production of downspout machinery have redefined performance, reliability, and user-friendliness. Today’s square downspout machine models are equipped with enhanced hydraulic shearing systems, automated length measurement, and memory-based programming platforms. The push toward higher production speed—with many machines reaching 20 meters per minute—translates into reduced labor costs and improved site throughput. Material handling enhancements, such as swappable profiles or quick-change cassettes for varying diameters, streamline the workflow for both stationary and jobsite downspout machine operators. Notably, new generation drives reduce energy consumption by up to 15%, benefiting high-volume operations. The integration of touch-screen interfaces and remote diagnostic modules further minimizes downtime, with error rates in operational faults now dropping below 1%. Operators now demand machines that deliver not just cost-effectiveness but robust, data-driven quality control.

Factory Benchmark: Manufacturer Comparison Table

To facilitate the selection process, it is vital to juxtapose key models by renowned manufacturers. Below is a comparative table that analyzes core features, price, and after-sales support among leading brands:

| Brand & Model | Profile Capability | Output Speed (m/min) | Energy Efficiency | Price Range (USD) | Warranty | Notable Features |

|---|---|---|---|---|---|---|

| SteelMaster SM-DSQ 2000 | Square/Round | 18 | High (−16% energy usage) | $24,000–$31,000 | 24 Months | Touchscreen, Auto Shear, Error Log |

| RainFlow ProSite 1500 | Square Only | 20 | Moderate | $17,500–$22,000 | 18 Months | Remote Diagnostics, Quick Cassette Change |

| GutterTech JT-Compact | Square/Round/Elliptical | 22 | Very High (−19%) | $36,000–$47,000 | 36 Months | Multi-profile, Energy Monitoring, Data Sync |

| BuildEdge DownPro 900 | Square Only | 15 | Standard | $13,500–$16,000 | 12 Months | Manual Settings, Site Portability |

This comparative overview clarifies that while initial pricing varies, features like after-sales service length, automatic error detection, and profile versatility are decisive for operational efficiency and maintenance outlay.

Custom Solutions and Configurations

Beyond standard models, the market for bespoke downspout machinery is rapidly expanding. Many manufacturers offer custom configurations to accommodate unique site requirements, unconventional downspout shapes, or integration with pre-existing production lines. For instance, 52% of large-scale contractors surveyed in 2023 expressed a preference for modular options—such as adjustable roll-forming dies or expandable frame designs—aimed at maximizing return on investment. These custom approaches often include dual feeding for mixed material use, advanced bending modules for decorative projects, or IoT-based performance analytics for predictive maintenance. Cost increments for custom orders typically add 10–25% to the base downspout machine price but can lead to significant downstream savings by optimizing production workflows and minimizing machine downtimes. Prospective buyers should consult with reputable vendors for an assessment of localization needs, compatibility analyses, and upgrade pathways.

Application Cases: Jobsite and Industrial Uses

The practical adoption of both portable and industrial-grade downspout systems demonstrates broad utility. In the commercial construction sector, jobsite downspout machine deployment reduces gutter installation timelines by 30%, helping contractors complete large-scale projects within condensed schedules. Industrial facilities benefit from high-output (over 1,200 meters/day) square downspout machine setups capable of producing precision-fit components for customized drainage systems. For example, a regional builder in Illinois leveraged a hybrid production fleet—combining ProSite and JT-Compact machines—to serve simultaneous projects across three counties, citing a 21% reduction in labor hours through equipment flexibility. Conversely, a facade specialist in Germany reported zero machine downtime for 2.5 years after implementing multi-profile GutterTech units with proactive diagnostics. These cases highlight the competitive edge and operational reliability gained by matching machine configuration to project scale and technical demand.

Budgeting for Value: Comprehensive Cost, Payback, and Service

Calculating total cost ownership is critical when considering jobsite downspout machine acquisition. Cost structure includes purchase price, operator training, spare part availability, and recurring maintenance. Typically, commercial users encounter annual servicing expenses amounting to 2–3% of the machine’s original price. The median payback period, accounting for increased project output and reduced manual errors, averages 13–18 months for mid-range units and up to 30 months for high-end customizable setups. Warranty provisions notably impact maintenance predictability; models offering three-year coverage often achieve higher resale value, contributing to a total life-cycle ROI boost of up to 18%. In this context, aftersales support, digital service logs, and the accessibility of technical upgrades are as crucial as the headline price, especially for contractors aiming for long-term growth and cost stabilization.

Conclusion: Informed Strategies for Downspout Machine Price Optimization

Final downspout machine price selection necessitates a multi-dimensional analysis—balancing initial investment against technological advantages, configurability, and long-term durability. As manufacturing and building standards evolve, emphasis on service accessibility and modular design grows in importance, often outpacing the allure of entry-level pricing. Buyers should prioritize models that deliver proven performance, adaptable operation, and robust warranty coverage to ensure superior project execution. By leveraging detailed benchmarking and scrutinizing lifecycle costs, companies are equipped to make investments that not only meet their immediate production needs but also secure lasting value in the competitive construction and remodeling sectors.

(downspout machine price)