EPS Sandwich Panel Production Line - Automated & Efficient

Navigating the Evolution of EPS Sandwich Panel Production Technology

The construction and infrastructure sectors are experiencing a profound transformation, driven by an escalating demand for sustainable, efficient, and high-performance building materials. At the forefront of this evolution stands the Eps Sandwich Panel Production Line, a sophisticated industrial solution designed to manufacture composite panels celebrated for their exceptional thermal insulation, structural integrity, and ease of installation. These panels, comprising a core of Expanded Polystyrene (EPS) foam sandwiched between two rigid facing layers, typically pre-painted galvanized iron (PPGI) or aluminum sheets, are revolutionizing building practices from residential structures to large-scale industrial complexes. The global market for sandwich panels is projected to grow significantly, fueled by urbanization, increasing energy efficiency regulations, and the rapid pace of modular construction. Understanding the intricacies of an advanced eps panel machine and its capabilities is paramount for businesses aiming to capitalize on this burgeoning market. This comprehensive guide delves into the technical core, operational nuances, and strategic advantages offered by modern eps sandwich panel production lines, providing B2B stakeholders with critical insights into investment justification, operational excellence, and long-term sustainability. We will explore the latest industry trends, detailed technical specifications, diverse application scenarios, and key considerations for selecting a reliable manufacturer, all underpinned by robust data and practical case studies. The efficiency gains, reduced construction timelines, and superior thermal performance achieved through these production lines are not merely incremental improvements but represent a paradigm shift in how we approach construction, emphasizing prefabrication and high-quality factory-controlled environments over traditional, often weather-dependent, on-site construction methods.

Modern `eps panel production line` systems are engineered to address the complexities of high-volume, precision manufacturing, integrating advanced automation and quality control mechanisms. The escalating costs of energy and the imperative for sustainable building solutions have positioned EPS sandwich panels as a preferred choice, given their superior U-values and significantly reduced thermal bridging. This directly translates into lower operational costs for heating and cooling in constructed buildings. Beyond energy efficiency, the inherent properties of EPS—lightweight, durable, and resistant to moisture absorption—make it an ideal core material. The continuous advancement in material science and machinery design has led to `eps sandwich panel machine` systems that are not only faster and more efficient but also capable of producing panels with enhanced fire resistance, soundproofing, and aesthetic versatility. For example, advancements in adhesive technology ensure robust bonding between the EPS core and the facing sheets, preventing delamination and ensuring long-term structural integrity. Furthermore, the ability to customize panel dimensions, thicknesses, and facing materials directly on the `eps sandwich panel line` offers unparalleled flexibility to meet diverse project specifications, from cold storage facilities requiring extreme insulation to architectural facades demanding specific aesthetic appeal. The integration of Industry 4.0 principles, such as IoT sensors for real-time monitoring and predictive maintenance, further elevates the operational efficiency and reliability of these sophisticated production lines, marking a significant leap forward from conventional manufacturing approaches.

Unpacking the Manufacturing Process: A Deep Dive into EPS Sandwich Panel Production

The manufacturing of EPS sandwich panels is a multi-stage, precision-engineered process that begins with raw material preparation and culminates in the finished, cut-to-size panels. A typical eps sandwich panel production line is a continuous operation, meticulously designed to ensure consistent quality and high output. The primary raw materials include pre-painted galvanized iron (PPGI) or aluminum coils for the facing sheets, high-density Expanded Polystyrene (EPS) blocks for the core, and specialized two-component polyurethane (PU) or single-component solvent-based adhesives for bonding. The process commences with uncoiling the metal sheets, which are then fed into a roll-forming machine. This machine precisely shapes the edges of the metal sheets to create interlocking profiles, such as tongue-and-groove or labyrinth joints, crucial for panel assembly and sealing during construction. Concurrently, the EPS blocks are fed into a cutting mechanism, often a hot-wire or CNC router, which precisely cuts the blocks into the desired thickness and width to form the panel's core. The accuracy of this cutting process is paramount to ensuring uniform panel thickness and optimal thermal performance.

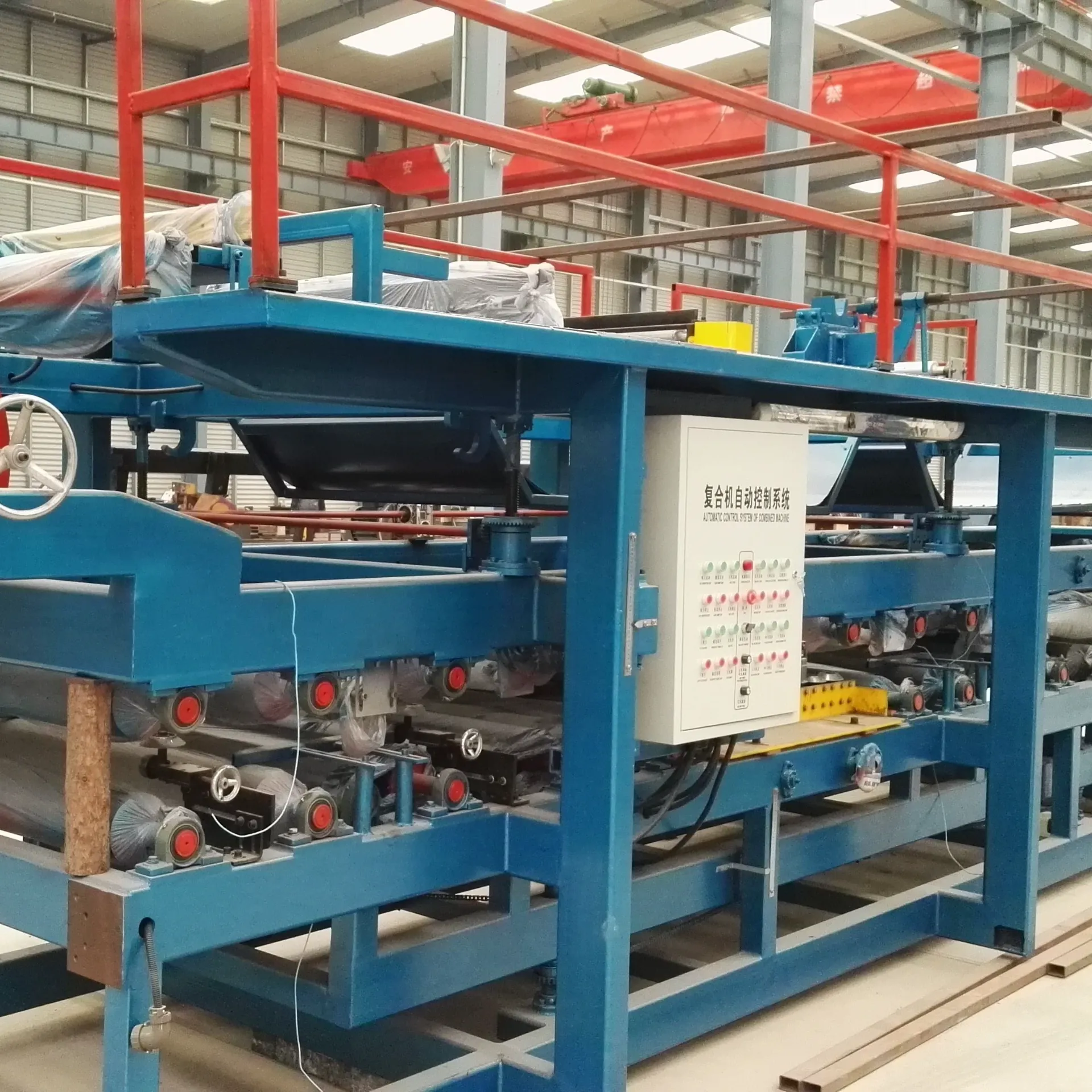

Following the shaping of the metal facings and the cutting of the EPS core, the next critical stage involves adhesive application. High-precision spraying or roller coating systems apply a uniform layer of adhesive onto the inner surfaces of both the top and bottom metal sheets. This adhesive formulation is engineered for strong bonding to both metal and EPS, ensuring the structural integrity of the composite panel over its long service life. The prepared EPS core is then precisely positioned between the two adhesive-coated metal sheets. The entire assembly then moves into a double-belt press, which applies controlled pressure and often heat, facilitating the curing of the adhesive and ensuring a strong, permanent bond between the EPS core and the metal facings. The pressure is carefully calibrated to prevent damage to the EPS while maximizing adhesive penetration and bonding strength. The speed of the line, the temperature of the press, and the curing time for the adhesive are all critical parameters that are continuously monitored and adjusted by the control system to maintain consistent product quality. State-of-the-art `eps panel production line` systems incorporate automated material handling and robotic placement of components to minimize human error and maximize throughput.

After exiting the double-belt press, the continuously formed composite panel proceeds to the cutting section. Here, precise cutting saws, often CNC-controlled, cut the continuous panel into pre-programmed lengths, as specified by customer orders. These saws are designed to deliver clean, burr-free cuts, ensuring perfect fit and finish for construction. Integrated slitting capabilities may also be present for producing panels of varying widths. Quality control measures are embedded throughout the entire production process. This includes real-time monitoring of sheet thickness, adhesive application consistency, panel dimensions, and bonding strength. Inspection standards typically adhere to international norms such as ISO 9001 for quality management systems and specific product standards like EN 14509 for self-supporting double skin metal faced insulating panels. Manufacturers of the `eps sandwich panel machine` often employ robust components, with machine frames constructed from high-strength steel (e.g., Q235 or Q345) and critical moving parts undergoing precision machining (e.g., CNC milling, grinding) and hardening processes to ensure durability and long operational lifespan, typically exceeding 15-20 years with proper maintenance. The selection of materials for the machine itself, such as high-grade tool steel for cutting blades and wear-resistant alloys for rollers, directly impacts the precision and longevity of the production process. The final panels are then stacked, packaged, and prepared for dispatch. The entire manufacturing process, from raw material input to finished product output, is streamlined for efficiency, minimal waste, and consistent quality, making the `eps sandwich panel line` a cornerstone of modern, rapid construction.

Technical Parameters and Core Specifications of Advanced Production Lines

Investing in an eps sandwich panel production line necessitates a thorough understanding of its technical parameters, which directly impact production capacity, panel quality, and operational efficiency. Key specifications include the line speed, panel thickness range, effective panel width, power consumption, and material compatibility. Modern `eps panel machine` systems are capable of continuous production speeds ranging from 4 to 8 meters per minute, with some high-end lines reaching up to 10 meters per minute for specific panel types. This speed directly translates into daily and annual production capacities, which are critical for ROI calculations. The versatility of the line to produce panels of varying thicknesses—typically from 50mm to 250mm, or even up to 300mm for specialized applications like cold storage—is also a significant factor, allowing manufacturers to cater to diverse market demands. Standard effective panel widths often fall between 950mm and 1200mm, aligning with common construction module dimensions. Energy consumption, particularly for heating and motor operations, is a critical operational cost; therefore, manufacturers often specify total power requirements, which can range from 80 kW to 200 kW depending on the level of automation and auxiliary equipment integrated.

Beyond these fundamental parameters, the technical sophistication of an `eps panel production line` is reflected in its control system, typically a PLC (Programmable Logic Controller) with a human-machine interface (HMI). Advanced PLC systems, often from renowned brands like Siemens, Allen-Bradley, or Mitsubishi, enable precise control over every stage of the production process, from roll forming and adhesive application to cutting and stacking. This level of automation ensures repeatable quality and minimizes material waste. The types of facing materials the line can handle are also crucial; while PPGI is standard, some lines can also process galvanized steel, aluminum, or even stainless steel, offering flexibility for specialized projects requiring enhanced corrosion resistance or aesthetic finishes. Core material compatibility extends beyond standard EPS to include fire-retardant EPS (FR-EPS) and sometimes other core materials if the adhesive system is adaptable. The structural components of the `eps sandwich panel machine` are built for heavy-duty industrial use, with precision-engineered rollers, durable cutting blades, and robust conveying systems. For instance, the main frame of the machine typically employs welded steel structures (e.g., H-beam or square tube) that undergo stress relief treatment to ensure long-term stability and prevent deformation under continuous operation. The hydraulic and pneumatic systems, responsible for applying pressure in the press and operating various clamps and cutters, feature high-quality pumps, valves, and cylinders to ensure reliable and consistent performance.

Detailed product specifications often include the maximum coil width and weight the uncoilers can accommodate, dictating the raw material handling capabilities. The number of forming stations in the roll former, typically 12-18 sets, determines the complexity of profiles it can create. Adhesives are typically two-component polyurethane (PU) systems, and the `eps sandwich panel line` integrates a precise mixing and dispensing unit to ensure optimal adhesive properties and curing. The curing tunnel or double-belt press length is another key indicator of production quality, with longer presses allowing for more effective curing at higher line speeds, contributing to superior panel bonding strength. For comprehensive data, a typical technical specification table for a mid-range production line is presented below, illustrating the critical performance metrics and system capabilities. These parameters are crucial for potential buyers to assess whether a specific `eps sandwich panel production line` aligns with their production volume targets, quality standards, and material specifications. Understanding these details empowers informed decision-making, ensuring the chosen equipment provides a competitive edge in the fast-evolving construction materials market, meeting current demands while offering scalability for future growth.

Typical Technical Specifications of an Advanced EPS Sandwich Panel Production Line

| Parameter | Specification Range | Notes |

|---|---|---|

| Production Speed | 4 - 8 meters/min (adjustable) | Dependent on panel thickness and adhesive curing time. |

| Panel Thickness Range | 50mm - 250mm | Customizable to 300mm+ for special orders. |

| Effective Panel Width | 950mm, 1000mm, 1150mm, 1200mm | Standard widths; customization available. |

| Facing Material Thickness | 0.3mm - 0.8mm (PPGI/Aluminum) | Max. 1.0mm for certain types of steel. |

| Coil Loading Capacity | Max. 5-10 Tons per uncoiler | Ensures continuous feeding. |

| Total Installed Power | Approx. 120 kW - 180 kW | Excludes adhesive mixing station. |

| Adhesive System | Two-component PU (Polyurethane) | High-pressure mixing and spraying. |

| Control System | PLC (Siemens/Mitsubishi/Allen-Bradley) with HMI | Fully automatic, precise control. |

| Line Length (Approx.) | 40 - 60 meters | Including uncoilers, roll former, press, and cut-off. |

| Operational Lifetime | 15-20+ years (with proper maintenance) | Robust components, high-quality manufacturing. |

Versatile Applications and Unparalleled Advantages of EPS Sandwich Panels

The widespread adoption of panels produced by an eps sandwich panel production line is a testament to their exceptional versatility and a multitude of inherent advantages across various industries. These panels are not just building materials; they are integrated solutions that address critical demands for energy efficiency, speed of construction, durability, and cost-effectiveness. In the commercial and industrial sectors, they are extensively used for factory buildings, warehouses, cold storage facilities, and cleanrooms. For cold storage, the superior thermal insulation provided by thick EPS panels (often 150mm to 250mm) significantly reduces energy consumption for refrigeration, leading to substantial operational cost savings. In contrast to traditional construction methods which might involve multiple layers of insulation and cladding, the single-component nature of an EPS sandwich panel simplifies the building envelope, offering both structural support and insulation in one prefabricated unit. This contributes to faster project completion times and reduced labor costs on site. The lightweight nature of the panels also lessens the structural load on foundations, potentially reducing overall construction material requirements.

Beyond large industrial structures, the output from an `eps panel production line` finds critical application in residential and modular building. Prefabricated homes, temporary shelters, and even multi-story residential buildings increasingly leverage these panels for their rapid assembly capabilities and thermal performance. In the agricultural sector, they are ideal for constructing livestock shelters, greenhouses, and food processing units, where controlled environments and hygiene are paramount. The metal facings, particularly PPGI with its protective coatings, offer excellent resistance to corrosion, moisture, and chemical exposure, making them suitable for environments found in petrochemical facilities, food processing plants, and water treatment works where traditional materials might degrade rapidly. Their low thermal conductivity (typically 0.038 - 0.045 W/m·K for EPS foam) directly translates into significant energy savings for heating and cooling, which is a key driver for adoption in regions with extreme climates. For instance, a 100mm thick EPS panel can provide insulation equivalent to a much thicker brick wall, while being significantly lighter and quicker to install.

The technical advantages provided by a quality `eps sandwich panel machine` and its output are multifaceted. Panels offer exceptional anti-corrosion properties due to the pre-painted galvanized or alu-zinc steel sheets, which are coated with protective layers (e.g., polyester, PVDF, SMP). This is particularly critical in aggressive environments like coastal areas or industrial zones. The fire-retardant grade of EPS (FR-EPS) can be used to improve fire safety ratings, meeting various building codes. Sound insulation properties, while not as high as rock wool panels, are still significant, contributing to a quieter interior environment. Furthermore, the ease of handling and installation significantly reduces labor requirements and construction timelines, leading to substantial cost efficiencies for developers and contractors. This prefabrication aspect minimizes on-site waste, aligns with sustainable building practices, and allows for greater quality control in a factory setting. For applications such as cleanrooms in the pharmaceutical or electronics industry, the smooth, non-porous surface of the metal facings facilitates easy cleaning and sterilization, preventing particle accumulation. The long service life of these panels, often exceeding 20-30 years, coupled with minimal maintenance requirements, further enhances their economic attractiveness, making the `eps sandwich panel line` a cornerstone for future-proof construction.

Innovations and Technological Superiority in EPS Panel Production

The continuous innovation within the `eps sandwich panel production line` sector is driven by demands for higher efficiency, greater precision, and enhanced product versatility. Modern production lines are a testament to advanced engineering, incorporating sophisticated automation, intelligent control systems, and robust mechanical designs. One significant advancement is the integration of high-speed, precision roll-forming technology. This ensures that the metal facing sheets are formed with exact profiles, crucial for seamless panel interlocking during installation and for maintaining structural integrity. The use of advanced servo-driven cutting systems allows for extremely accurate panel lengths and minimizes material waste, critical for optimizing raw material utilization and reducing operational costs. These systems can execute precise cuts on the fly, adapting to varying production speeds and panel length requirements without interruption. Furthermore, automated stacking and packaging systems reduce labor intensity at the end of the line, improving safety and overall throughput. The automation extends to real-time process monitoring, where sensors track parameters such as adhesive application rate, temperature, and pressure within the curing press.

Another area of technological superiority lies in the adhesive application system of the `eps panel machine`. Precision metering pumps ensure the correct mixing ratio of two-component polyurethane adhesives, vital for optimal bonding strength and curing time. Advanced spray nozzles or roller coating systems ensure a uniform and controlled application of adhesive across the entire surface of the metal sheets, preventing inconsistencies that could lead to delamination. The double-belt press, a core component of any `eps panel production line`, has also seen significant improvements. Modern presses feature segmented heating zones and adaptive pressure controls, allowing for precise temperature and pressure profiles to be applied along the panel's length, optimizing adhesive curing for different panel thicknesses and environmental conditions. This ensures superior adhesion and panel flatness, which are critical for both aesthetic appeal and structural performance. The robust construction of these presses, often utilizing high-strength alloy steels for the main components and precise mechanical alignment, ensures long-term stability and minimal deformation under continuous high-pressure operation.

The adoption of Industry 4.0 principles is increasingly evident in the latest generation of `eps sandwich panel machine` systems. This includes the implementation of IoT sensors for real-time data collection on machine performance, energy consumption, and material flow. This data is fed into centralized control systems, enabling predictive maintenance, fault diagnosis, and operational optimization. For example, anomaly detection in motor current draw or temperature readings can signal impending mechanical issues, allowing for proactive maintenance and minimizing costly downtime. The HMI (Human-Machine Interface) systems have become more intuitive, providing operators with comprehensive visual feedback and control over every parameter of the `eps sandwich panel line`. Remote access capabilities via secure network connections allow manufacturers or technical support teams to diagnose issues and provide assistance from anywhere in the world, significantly reducing response times for troubleshooting. These technological advancements collectively enhance the reliability, efficiency, and overall productivity of the production line, ensuring a consistent output of high-quality EPS sandwich panels that meet stringent international standards and provide superior value to end-users in the construction sector. The ability to monitor production data, adjust parameters on the fly, and integrate with enterprise resource planning (ERP) systems represents a substantial leap in manufacturing intelligence, positioning modern production lines as smart factories capable of responding dynamically to market demands.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer for an eps sandwich panel production line is a critical strategic decision that impacts not only the initial investment but also long-term operational success, product quality, and return on investment. The market offers a diverse range of suppliers, from established industry leaders to emerging innovators, each with unique strengths. Key criteria for manufacturer comparison include their track record and industry reputation, the level of technological sophistication in their `eps panel machine` offerings, post-sales support, spare parts availability, and customization capabilities. A reputable manufacturer will typically have a well-documented history of successful installations, positive client testimonials, and industry certifications such as ISO 9001 for quality management and CE marking for European compliance. Visiting their manufacturing facility, if possible, provides invaluable insight into their engineering capabilities, quality control processes, and the robustness of their machine components. It's crucial to assess the origin and quality of critical components, such as PLC systems (e.g., Siemens, Mitsubishi), electrical components (e.g., Schneider, ABB), and hydraulic systems (e.g., Rexroth), as these significantly influence the reliability and longevity of the `eps panel production line`.

Beyond standard offerings, the ability of a manufacturer to provide customized solutions is a major differentiator. While standard `eps sandwich panel machine` models cater to general market demands, specific business models or project requirements may necessitate tailored configurations. This could include higher production speeds, broader panel thickness ranges, specialized roll-forming profiles for unique interlocking designs, or integration with specific ERP systems for streamlined operations. For instance, a client focusing on cold storage solutions might require a line optimized for producing thicker panels (up to 300mm), while another specializing in architectural facades might prioritize aesthetics and require special facing material handling capabilities. A proactive manufacturer will engage in thorough consultations to understand a client's specific needs, offering modular designs that allow for future upgrades or expansions. This flexibility ensures that the initial investment is future-proof and scalable with business growth. Customization extends to aspects like the length of the curing press, the type and number of uncoilers, and the level of automation desired at the stacking and packaging end.

After-sales support and spare parts availability are non-negotiable considerations. Even the most robust `eps sandwich panel line` will eventually require maintenance or replacement parts. A strong manufacturer will offer comprehensive installation supervision, operator training programs, and readily available technical support (remote and on-site). A well-stocked inventory of spare parts, especially for wear-and-tear components like cutting blades, rollers, and critical electrical/hydraulic parts, is crucial to minimize downtime. Long-term service contracts and preventive maintenance programs can also offer peace of mind and ensure optimal machine performance over its entire lifespan. Companies like YOWIN MACHINE, with a demonstrated commitment to innovation, quality manufacturing, and extensive global service networks, stand out in this competitive landscape. Their long service years and established client base serve as a strong indicator of reliability and trustworthiness. Engaging with a manufacturer that not only sells equipment but also offers expertise in optimizing production processes and material sourcing can be invaluable, fostering a true partnership that goes beyond a transactional relationship and ensures sustained operational excellence for your eps sandwich panel production line.

Ensuring Trust and Authority: Quality Assurance, Certifications, and Support

For B2B buyers of a sophisticated capital investment like an eps sandwich panel production line, establishing trust and verifying the manufacturer's authority are paramount. This goes beyond technical specifications to encompass the company's commitment to quality, its adherence to international standards, and the robustness of its post-sales support infrastructure. A credible manufacturer will proudly display their certifications, such as ISO 9001:2015 for Quality Management Systems, indicating a systematic approach to ensuring product and service quality. Compliance with regional standards like CE (Conformité Européenne) marking for machinery sold in the European Economic Area demonstrates adherence to essential health, safety, and environmental protection requirements. For the EPS panels themselves, relevant product standards like EN 14509 (Self-supporting double skin metal faced insulating panels) provide a benchmark for performance, fire resistance, and durability. Reputable manufacturers will also have a history of successful client installations and can provide references or case studies demonstrating their `eps panel machine`'s performance in real-world scenarios.

Authoritativeness is further reinforced by the manufacturer's long service history, significant market share, and strategic partnerships with leading component suppliers (e.g., Siemens for PLC, Rexroth for hydraulics). Companies that have been operating in the industry for several decades typically possess a depth of experience and technical expertise that newer entrants might lack. They have refined their `eps panel production line` designs over time, incorporating feedback from a vast customer base and adapting to evolving industry requirements. Test data, often generated by independent third-party laboratories, on parameters such as panel bonding strength, thermal conductivity, and fire ratings, provides objective evidence of quality and performance. Manufacturers should be transparent about their testing protocols, whether they adhere to ASTM, ANSI, or other relevant international standards. Service case studies detailing successful installations in diverse geographical locations and challenging environments further build confidence, showcasing the manufacturer's global reach and adaptability. This level of detail and transparency in documentation and historical performance builds a strong foundation of trust.

Trustworthiness extends significantly to the after-sales services. A robust warranty program, typically ranging from 12 to 24 months for major components, signals confidence in the `eps sandwich panel machine`'s reliability. Clear and precise statements regarding delivery cycles, often 60-90 working days depending on customization, manage client expectations effectively. Crucially, a responsive customer support system, including readily available technical assistance (via phone, email, or dedicated online portals), on-site installation and commissioning services, and comprehensive operator training, ensures smooth transitions and sustained production. The provision of detailed operation manuals, troubleshooting guides, and recommended spare parts lists empowers clients to manage their `eps sandwich panel line` effectively. A well-organized spare parts supply chain is vital to minimize downtime, and a reliable manufacturer will often stock essential wear parts for immediate dispatch. Ultimately, the cumulative effect of these quality assurances, certifications, authoritative industry presence, and unwavering customer support transforms a transactional purchase into a long-term, trustworthy partnership, ensuring the client's investment in an eps sandwich panel production line yields maximum returns and operational stability.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an Eps Sandwich Panel Production Line?

A: The standard lead time for manufacturing and delivery typically ranges from 60 to 90 working days, depending on the level of customization and the specific configuration of the `eps sandwich panel production line`. This period includes design, component sourcing, fabrication, assembly, and initial factory testing.

- Q: What kind of after-sales support can I expect?

A: Comprehensive after-sales support includes on-site installation supervision and commissioning, extensive operator and maintenance training, readily available technical assistance (online and phone support), and a robust spare parts supply chain. We also offer optional long-term maintenance contracts for sustained peak performance of your `eps panel machine`.

- Q: What are the power requirements for operating an `eps panel production line`?

A: The total installed power for a typical `eps panel production line` ranges approximately from 120 kW to 180 kW. This depends on the specific machine configuration, the extent of automation, and the inclusion of auxiliary equipment like the adhesive mixing station. Specific power requirements will be provided in the detailed technical proposal.

- Q: Can the production line handle different types of metal facing sheets?

A: Yes, our `eps sandwich panel machine` systems are designed to be versatile. While pre-painted galvanized iron (PPGI) is standard, the lines can typically process various types of metal sheets including galvanized steel, aluminum, and sometimes stainless steel, depending on the specific roll former design and material handling capabilities required by the customer.

- Q: What is the expected lifespan of the `eps sandwich panel line`?

A: With proper regular maintenance and operation according to manufacturer guidelines, an advanced `eps sandwich panel production line` is designed for a long operational lifespan, typically exceeding 15 to 20 years. This longevity is ensured by using high-quality, durable components and robust engineering practices in the machine's construction.

Conclusion and Future Outlook for EPS Sandwich Panel Production

The increasing global emphasis on sustainable construction, energy efficiency, and rapid deployment of infrastructure continues to position the eps sandwich panel production line as a cornerstone technology for modern building materials manufacturing. As explored throughout this article, these sophisticated lines represent a fusion of advanced mechanical engineering, intelligent automation, and precise material handling, culminating in the efficient production of high-performance EPS sandwich panels. The panels themselves offer a compelling array of benefits, including superior thermal insulation, structural integrity, resistance to environmental factors like corrosion, and significant reductions in construction timelines and labor costs. The versatility of an `eps panel machine` to produce panels of varying thicknesses, profiles, and facing materials ensures adaptability to a wide spectrum of applications, from temperature-controlled environments to aesthetically driven architectural projects. For B2B stakeholders, the decision to invest in an advanced `eps panel production line` is not merely an equipment purchase but a strategic commitment to operational excellence, market competitiveness, and long-term sustainability in the evolving construction landscape.

Looking ahead, the future of the `eps sandwich panel machine` industry is poised for further innovation. We anticipate continued advancements in automation, potentially incorporating more AI-driven analytics for predictive maintenance and even self-optimization of production parameters. The development of new adhesive technologies that offer faster curing times or enhanced environmental properties will further boost production efficiency and material versatility. Furthermore, the integration of advanced robotics for complex tasks like panel stacking and bespoke cutting will lead to even greater precision and labor savings. As regulatory frameworks continue to push for greener building practices, the emphasis on producing EPS panels with enhanced fire resistance, improved recyclability, and lower embodied energy will intensify, driving research and development efforts within the `eps sandwich panel line` sector. The capacity for these production lines to facilitate modular and prefabricated construction will become increasingly critical in addressing global housing shortages and accelerating infrastructure development, making them indispensable assets for forward-thinking manufacturers.

Ultimately, partnering with a reputable and technologically advanced manufacturer is crucial for realizing the full potential of an eps sandwich panel production line. Such a partnership transcends the initial transaction, encompassing comprehensive technical support, training, and a commitment to ongoing innovation. The ability to customize a line to specific production needs, coupled with robust after-sales service and a transparent approach to quality assurance, ensures that the investment delivers consistent, high-quality output and a strong competitive edge. As the construction industry continues its trajectory towards smarter, faster, and more sustainable methods, the continuous EPS sandwich panel production line will undoubtedly remain a pivotal technology, driving efficiency and innovation worldwide. The strategic implementation of these advanced manufacturing solutions will be key for businesses aiming to meet the escalating demands for modern, energy-efficient, and durable building materials across diverse global markets.

References

- Grand View Research: Sandwich Panels Market Size, Share & Trends Analysis Report (For market growth projections and trends analysis).

- International Organization for Standardization (ISO): ISO 9001 - Quality management (For general quality management system standards).

- European Commission: CE Marking (For European compliance and safety regulations for machinery).

- CEN European Committee for Standardization: EN 14509 (For specific product standards related to self-supporting metal faced insulating panels).