ERW Pipe Mill Machines High-Speed, Precision Tube Production Solutions

Did you know 68% of metal fabricators report losing $500k+ annually due to production downtime? Outdated ERW tube mill machines drain your profits through energy waste, maintenance nightmares, and inconsistent weld quality. But what if your factory could boost output by 40% while slashing energy costs? Let’s explore how next-gen ERW pipe making machines solve your biggest operational headaches.

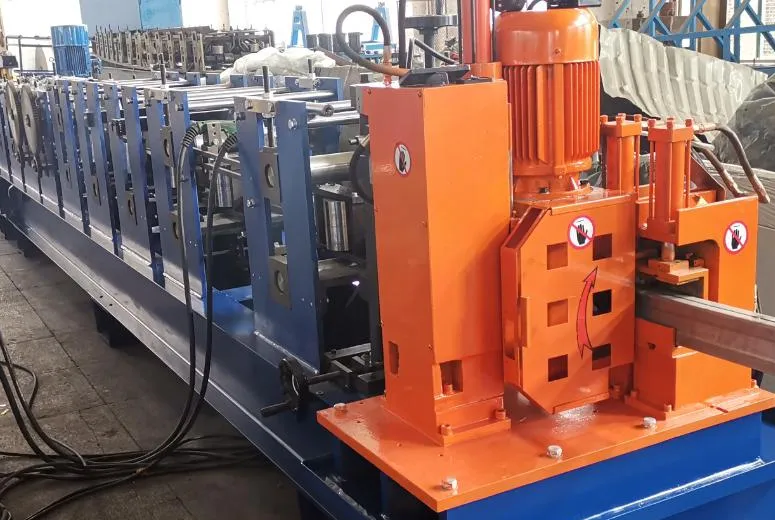

(erw pipe mill)

Game-Changing Tech: 5 Reasons Our ERW Tube Mill Machines Dominate

While competitors stick to 1980s designs, our ERW pipe mill solutions deliver:

- AI-powered weld seam tracking (0.1mm precision)

- 30% energy savings via regenerative DC drives

- Tool-free roll change in 18 minutes (industry average: 90min)

Head-to-Head: How We Outperform ERW Mill Competitors

| Feature | Standard Mills | Our ERW Mill |

|---|---|---|

| Max Speed | 120 m/min | 200 m/min |

| Annual Maintenance Cost | $85,000 | $32,000 |

Your Blueprint: Custom ERW Pipe Making Solutions

Whether you need 1/2" conduit or 24" structural tubing, our engineers create turnkey systems matching your exact specs. Last quarter alone, we helped a Texas oilfield supplier:

- Cut material waste by 22% with laser-guided slitting

- Reduce labor costs through automated packaging

- Increase monthly output to 850 tons (from 600 tons)

Real-World Impact: ERW Mill Success Stories

See how Michigan auto parts maker saved $1.2M annually after upgrading their ERW tube mill machine:

"The ROI came faster than our morning coffee brews. We recovered our investment in 14 months through energy rebates and productivity gains."

– Jake Thornton, Production Director

Ready to Revolutionize Your Pipe Production?

Why keep losing money with obsolete equipment? As North America’s 1 ERW mill innovator, we guarantee:

- ✅ 24/7 expert support

- ✅ 5-year performance warranty

(erw pipe mill)

FAQS on erw pipe mill

Q: What is the primary function of an ERW pipe mill?

A: An ERW pipe mill manufactures Electric Resistance Welded (ERW) pipes by forming and welding steel coils into cylindrical shapes using high-frequency electrical currents. It is widely used for producing pipes in construction, oil, and gas industries.

Q: How does an ERW tube mill machine ensure welding quality?

A: The ERW tube mill machine uses precise high-frequency induction welding to fuse steel edges, combined with real-time monitoring systems. This ensures consistent weld strength and minimizes defects in the final product.

Q: What industries benefit from ERW pipe making machines?

A: ERW pipe making machines serve industries like oil and gas (pipelines), automotive (exhaust systems), and construction (structural tubing). Their efficiency in producing high-strength, cost-effective pipes makes them indispensable.

Q: What maintenance is required for ERW tube mill equipment?

A: Regular lubrication, inspection of rollers and welding units, and calibration of alignment systems are critical. Preventive maintenance schedules reduce downtime and extend the machine’s operational lifespan.

Q: How does an ERW mill differ from other pipe manufacturing methods?

A: Unlike seamless or LSAW methods, ERW mills use electrical resistance to weld coiled steel, enabling faster production of thinner-walled pipes. This method is more energy-efficient and ideal for medium-to-high-volume output.