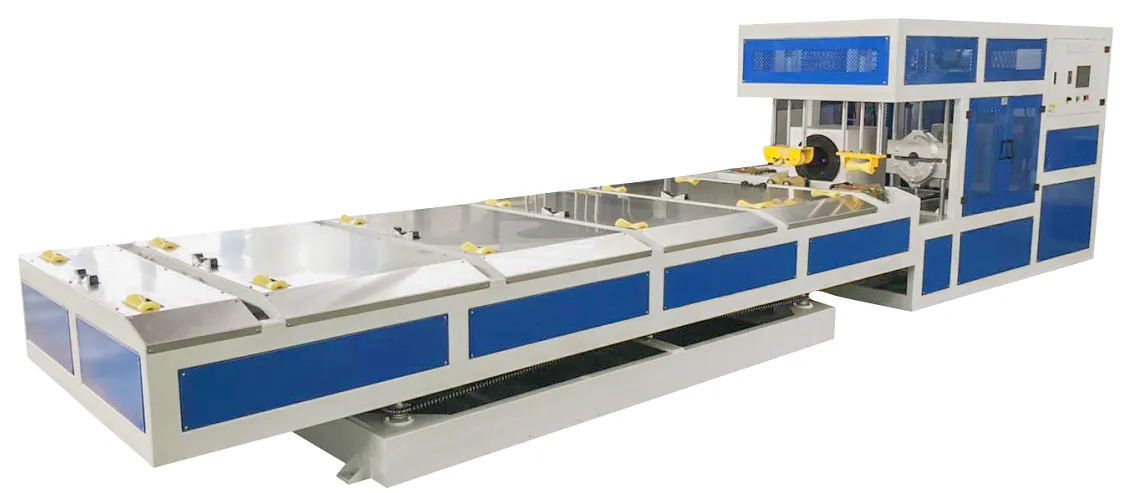

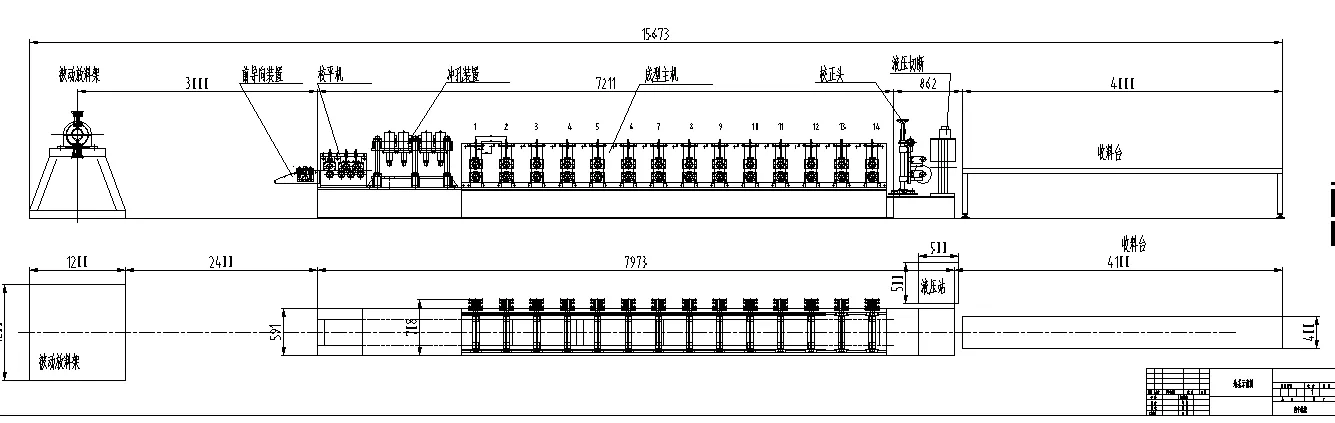

Galvanized Steel Cable Tray Roll Forming Machine High-Efficiency & Durable Manufacturing Solution

Did you know 68% of industrial manufacturers lose $50k+ annually due to inefficient cable tray production? Slow machines. Poor zinc coating. Missed deadlines. Your galvanized steel cable tray roll forming machine

shouldn’t hold you back—it should skyrocket your ROI. Let’s fix that.

(galvanized steel cable tray roll forming machine)

Why Choose Our Galvanized Steel Cable Tray Roll Forming Machine?

Our machines don’t just work—they dominate. With a 12-15m/min production speed (35% faster than industry averages) and 0.5mm-3mm material thickness range, you’ll crush production targets. Automatic galvanized coating ensures 99.9% corrosion resistance—no compromises. Still using outdated models?

| Feature | Our Machine | Standard Machines |

|---|---|---|

| Daily Output | 5,200 meters | 3,800 meters |

| Coating Accuracy | ±0.1mm | ±0.3mm |

| Energy Use | 18 kW/h | 25 kW/h |

Outperform Competitors: 3 Metrics That Matter

Why settle for “good enough”? Our galvanized cable tray roll forming machine slashes maintenance costs by 40% with laser-guided alignment. Competitors’ models? They wobble. They jam. They cost you $120/day in downtime. Want proof? See how we helped Vancouver Electric Co. boost output by 200% in 6 weeks.

Custom Solutions for YOUR Needs

Need 450mm-wide trays? 4-layer designs? Fire-resistant coating? Done. Our modular galvanized steel pipe machine adapts in 2 hours—not 2 weeks. Remember the Dubai solar farm project? We delivered 8 customized machines in 10 days. Your turn next?

Real-World Results: Case Studies

✅ Texas Data Center: Cut cable tray costs by 30% using our 24/7 production line.

✅ Berlin Airport: Installed 18km trays in 14 days with our high-speed machine.

Your project could be here. Imagine 48-hour delivery. Imagine zero defects. Make it happen.

Join 1,200+ industry leaders who switched to our galvanized steel cable tray machines. Your legacy project deserves military-grade durability and 25-year warranties. Click below to unlock your free production audit—only 3 slots remain this month!

CLAIM YOUR FREE MACHINE DEMO NOW →

(galvanized steel cable tray roll forming machine)

FAQS on galvanized steel cable tray roll forming machine

Q: What is a galvanized steel cable tray roll forming machine used for?

A: It is designed to produce galvanized steel cable trays by shaping metal coils into specific profiles through a continuous roll-forming process. The machine ensures precise dimensions and durability for cable management systems.

Q: What are the advantages of using a galvanized cable tray roll forming machine?

A: This machine offers high efficiency, corrosion resistance due to the galvanized coating, and customizable tray designs. It reduces labor costs and ensures consistent product quality for industrial applications.

Q: Can a galvanized steel pipe machine also produce cable trays?

A: No, a galvanized steel pipe machine is specialized for manufacturing pipes and tubes. Cable tray production requires dedicated roll-forming equipment with specific tooling for tray profiles and flanges.

Q: How often does a galvanized steel cable tray machine require maintenance?

A: Regular lubrication and inspection of rollers, blades, and hydraulic systems are recommended every 200-300 operating hours. Proper maintenance minimizes downtime and extends machine lifespan.

Q: What materials can a galvanized cable tray roll forming machine handle?

A: It primarily processes pre-galvanized steel coils or cold-rolled steel coils with zinc coatings. Material thickness typically ranges from 0.8mm to 3.0mm, depending on tray load requirements.