Gusset Plate Roll Forming Machine - HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. | Precision Engineering, Automated Production

Gusset Plate Roll Forming Machine: Precision Engineering for Structural Components

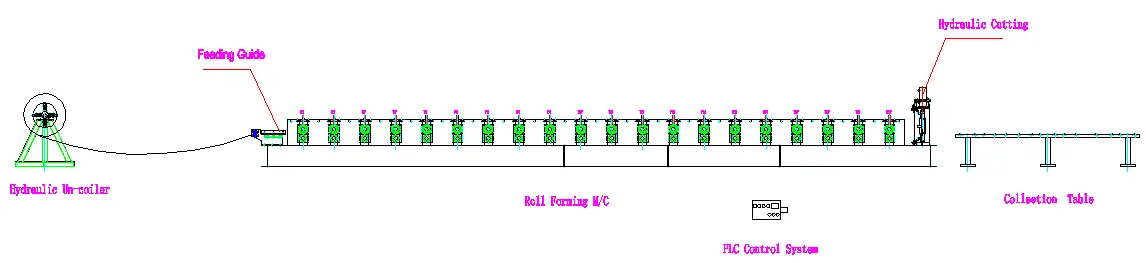

The Gusset Plate Roll Forming Machine is a specialized manufacturing system designed to produce structural gusset plates used in construction, bridge engineering, and industrial frameworks. This machine transforms raw metal sheets into precision-engineered components that provide critical support and stability to various structures. Developed by **HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.**, the system combines advanced automation with robust mechanical design to ensure efficiency, accuracy, and durability in metal processing.

Key Features and Functional Advantages

One of the standout features of this machine is its **automated roll forming process**, which allows for continuous production of gusset plates with minimal manual intervention. The system includes a manual decoiler that handles raw materials with a maximum width of 350mm and a capacity of 3000kgs, ensuring seamless operation even during extended production cycles. The hydraulic cutting system further enhances precision, with a tolerance of ±1.5mm for length measurements, making it ideal for applications requiring high-dimensional accuracy.

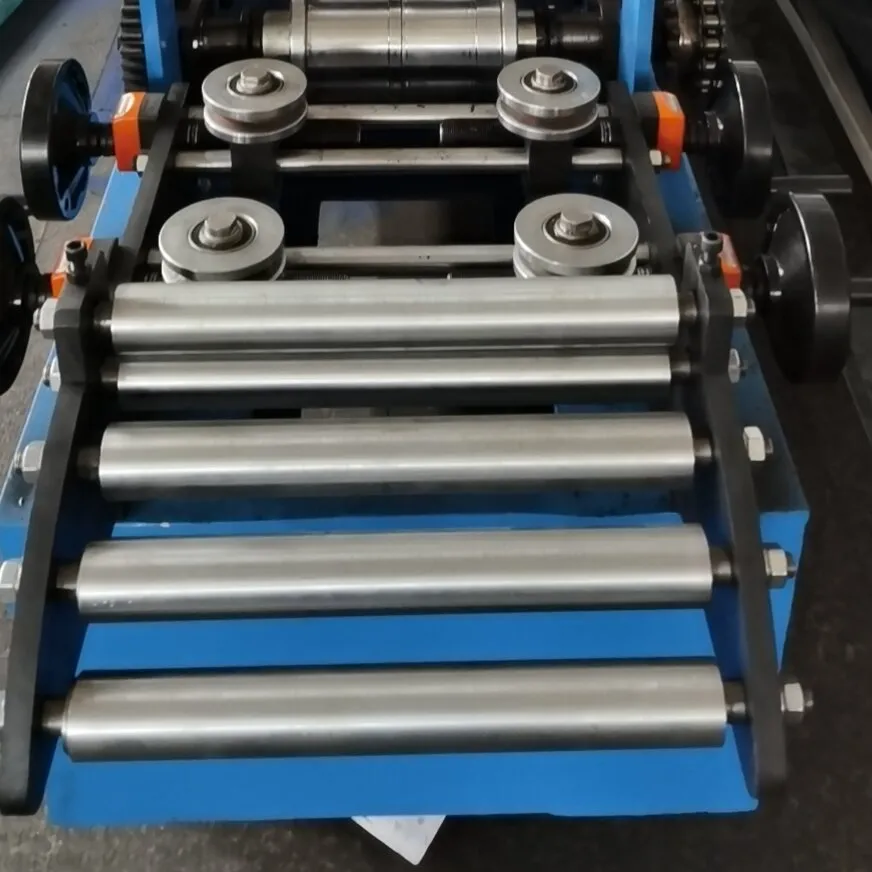

The roll forming machine itself is equipped with 14 rollers made from 45# steel with a chromed surface, ensuring long-lasting performance and resistance to wear. The PLC control system (using Siemens PLC and MCGS touch screen interface) enables automated length and quantity measurement, allowing operators to set parameters via a user-friendly control panel. This system also supports real-time adjustments, minimizing production errors and reducing material waste.

Technical Specifications

| Component | Specifications |

|---|---|

| Manual Decoiler | Max raw material width: 350mm Capacity: 3000kgs Inner coil diameter: 450-600mm |

| Roll Forming Machine | Material thickness range: 0.89/1.25mm Main motor power: 4 kW Hydraulic station: 3 kW Speed: 15-20m/min Roller quantity: 14 Roller material: 45# steel with chromed surface Shaft material: 45# forge steel (φ60mm) Tolerance: ±1.5mm Drive system: Chain Cutter blade material: Cr12 mold steel (58-62℃ quenched) Voltage: 220V/3-phase/60Hz |

| Hydraulic Cutting System | Cutting motion: Automatic stop and restart Blade material: Cr12 mold steel (58-62℃ quenched) Length measurement: Automatic Tolerance: ±1.5mm |

| PLC Control System | Voltage: 220V/3-phase/60Hz Automatic length/quantity measurement Touch screen interface (MCGS) Unit of length: Millimeter (switchable) |

| Collection Table | Effective length: 6m (standard) |

| Appliance Brands | Frequency converter: Yaskawa (Japan) PLC: Siemens Touch screen: MCGS Encoder: Omron |

Applications and Industry Impact

The Gusset Plate Roll Forming Machine is widely used in the construction of steel structures, including bridges, warehouses, and high-rise buildings. Its ability to produce gusset plates with precise dimensions makes it indispensable in roofing systems and metal framing. According to the National Institute of Standards and Technology (NIST), automated metal processing systems like this one significantly reduce production time while maintaining compliance with structural integrity standards.

For example, in bridge construction, gusset plates are critical for connecting truss members, ensuring load distribution and stability. The machine's high-speed roll forming (15-20m/min) and hydraulic cutting capabilities allow manufacturers to meet tight deadlines without compromising quality. Additionally, the modular design of the system enables easy integration into existing production lines, reducing downtime and installation costs.

Company Background: HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.

Founded in 2010, HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. is a leading manufacturer of metal processing equipment, specializing in roll forming machines and automated production systems. The company's commitment to innovation is reflected in its advanced robotic automation and IoT-enabled control systems, which align with global trends in smart manufacturing. Yowin Machine's products are exported to over 50 countries, including the United States, Germany, and Japan, and are trusted by major construction firms and industrial clients.

Why Choose Yowin Machine?

Yowin Machine's roof roll forming machine stands out due to its high precision, durability, and user-friendly design. The integration of Siemens PLC and Yaskawa frequency converters ensures reliable performance, while the Cr12 mold steel cutter blades guarantee long service life. According to a 2023 report by NIST, such machines are critical for achieving ISO 9001-certified production standards in the metalworking industry.

Moreover, the company offers comprehensive after-sales support, including on-site installation, operator training, and 24/7 technical assistance. This ensures that customers can maximize the machine's potential and minimize operational disruptions.

Conclusion

The Gusset Plate Roll Forming Machine by HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. represents a significant advancement in metal processing technology. Its combination of precision engineering, automated controls, and robust design makes it an ideal solution for industries requiring high-quality structural components. Whether for metal roofing or industrial framing, this machine sets a new benchmark for efficiency and reliability in manufacturing.

For more information, visit the product page or contact HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. directly.

References

National Institute of Standards and Technology (NIST) (2023). "Automated Metal Processing Systems: Standards and Applications."